High-temperature-resistant composite diaphragm for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and composite diaphragms, applied in secondary batteries, battery pack components, circuits, etc., can solve the problem of not being able to fully utilize the high-temperature resistant nanofiber porous membrane, increase the thermal dimensional stability of the diaphragm, and the self-discharge rate of the battery Advanced problems, to achieve the effect of simple and easy preparation process, improved mechanical properties, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

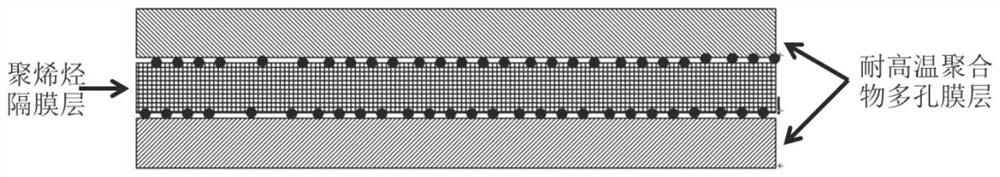

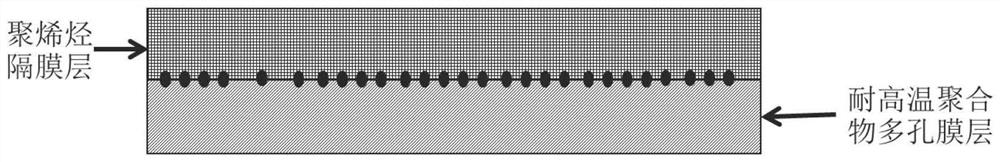

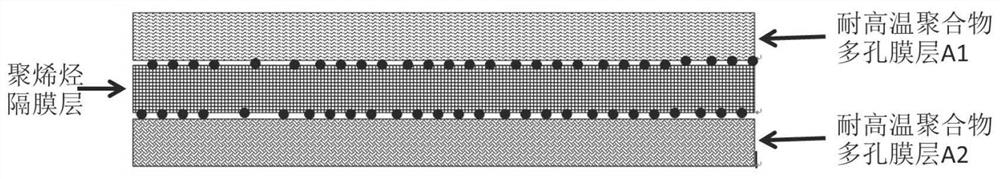

Method used

Image

Examples

Embodiment 1

[0034] A: Preparation of polymer porous membrane by electrospinning method:

[0035] 10g of PAN with a molecular weight of 150,000 was added to 90g of N-methylpyrrolidone (NMP), stirred at 25°C until the PAN was completely dissolved, the solution became transparent, and an electrospinning solution with a mass fraction of 10% was obtained. The spinning solution was injected into the electrospinning machine to carry out electrospinning under the conditions of 15KV voltage and a distance of 5 cm between the spinning head and the receiving substrate to obtain a polymer nanofiber porous membrane. After rolling, the porosity was adjusted to 35%, and the thickness was 10 μm. High temperature resistant polymer porous membrane (A 1 1), high temperature resistant polymer porous membrane (A 2 1);

[0036] B: The two surfaces of the polyethylene diaphragm B1 with a thickness of 12 μm are modified, and the surface is coated with a PVDF adhesive solution with a concentration of 4%, and th...

Embodiment 2

[0039] A: Preparation of polymer porous membrane by electrospinning method:

[0040] The polyimide precursor is synthesized by solution condensation polymerization in DMF solvent with diamine and dibasic acid anhydride monomers at a molar ratio of 1:1

[0041] ——Polyamic acid solution, to obtain a polyamic acid electrospinning solution with a solid content of 25%, inject the prepared electrospinning solution into an electrospinning machine and perform electrospinning under the conditions of 50KV voltage and a distance of 20cm from the spinning head to the receiving substrate , to make a polyamic acid nanofiber membrane; place the prepared polyamic acid nanofiber membrane in a hot furnace, raise the temperature to 450°C, and keep it for 0.1h to obtain a polyimide (PI) nanofiber porous membrane with a thickness of 2 microns, porosity 60%; as a high temperature resistant polymer porous membrane (A 1 2), high temperature resistant polymer porous membrane (A 2 2);

[0042] B: Th...

Embodiment 3

[0045] A: Preparation of polymer porous membrane by electrospinning method:

[0046] Add 8g of P84 with a molecular weight of 300,000 to 92g of N-methylpyrrolidone (NMP), stir at 70°C until completely dissolved, the solution becomes transparent, and an electrospinning solution with a mass fraction of 8% is obtained. The prepared electrospinning The silk liquid is injected into the electrospinning machine to carry out electrospinning under the condition of 36KV voltage and 15cm distance between the spinning head and the receiving substrate to obtain a polymer nanofiber porous membrane with a thickness of 10 μm and a porosity of 85% as a high temperature resistant polymer porous membrane ( A 1 3), high temperature resistant polymer porous membrane (A 2 3);

[0047] B: Modify the polyethylene separator B3 with a thickness of 25 μm, and apply 2kw plasma to irradiate the polyolefin separator for 5 minutes to make the surface have polar groups, so as to have better interfacial adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com