Shrinkage-reducing polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of building materials, can solve the problems of adverse effects of concrete strength, difficulty in determining the amount of expansion agent used, etc., and achieve the effects of improving shrinkage phenomenon, high reproducibility and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A shrinkage-reducing polycarboxylate water reducer proposed by the present invention includes the following raw materials in parts by weight: 100 parts of polyethylene glycol monomethyl ether, 9 parts of methacrylic acid, 0.06 parts of dibutyl maleate, 2,6 -0.8 parts of nonadienol, 0.6 parts of sodium 4-cumene sulfonate, 1.5 parts of initiator, 0.18 parts of catalyst, 1.4 parts of diafenthiuron, 1.4 parts of 4-hydroxymethylimidazole hydrochloride, 10 parts of isopropanol parts, 78 parts of water;

[0022] Among them, the average molecular weight of polyethylene glycol monomethyl ether is 5000; the initiator is composed of potassium permanganate and oxalic acid with a mass ratio of 1:1; the catalyst is composed of ferric iron tetroxide and 1,10-Phenanthroline is compounded, and the specific compounding method is as follows: Take ferric oxide with corresponding specific gravity, add absolute ethanol with 5 times the mass of ferric oxide, raise the temperature to 70°C, sti...

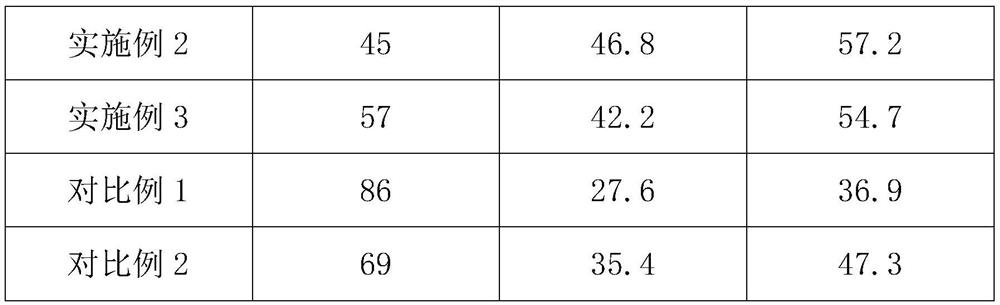

Embodiment 2

[0028] A shrinkage-reducing polycarboxylate water-reducer proposed by the present invention includes the following raw materials in parts by weight: 96 parts of polyethylene glycol monomethyl ether, 12 parts of methacrylic acid, 0.1 part of dibutyl maleate, 2,6 -0.5 parts of nonadienol, 0.4 parts of sodium 4-cumene sulfonate, 2 parts of initiator, 0.16 parts of catalyst, 1.9 parts of diafenthiuron, 0.9 parts of 4-hydroxymethylimidazole hydrochloride, 12 parts of isopropanol parts, 75 parts of water;

[0029] Among them, the average molecular weight of polyethylene glycol monomethyl ether is 5000; the initiator is composed of potassium permanganate and oxalic acid with a mass ratio of 1:1; the catalyst is composed of ferric iron tetroxide and 1,10-Phenanthroline is compounded, and the specific compounding method is as follows: Take ferric oxide with corresponding specific gravity, add absolute ethanol with 6 times the mass of ferric oxide, raise the temperature to 70°C, stir fo...

Embodiment 3

[0035] A shrinkage-reducing polycarboxylate water reducer proposed by the present invention includes the following raw materials in parts by weight: 92 parts of polyethylene glycol monomethyl ether, 18 parts of methacrylic acid, 0.14 parts of dibutyl maleate, 2,6 -0.3 parts of nonadienol, 0.2 parts of sodium 4-cumene sulfonate, 2.5 parts of initiator, 0.14 parts of catalyst, 2.4 parts of diafenthiuron, 0.7 parts of 4-hydroxymethylimidazole hydrochloride, 15 parts of isopropanol parts, 72 parts of water;

[0036] Among them, the average molecular weight of polyethylene glycol monomethyl ether is 5000; the initiator is composed of potassium permanganate and oxalic acid with a mass ratio of 1:1; the catalyst is composed of ferric iron tetroxide and 1,10-Phenanthroline is compounded, and the specific compounding method is as follows: Take ferric oxide with corresponding specific gravity, add absolute ethanol with 8 times the mass of ferric oxide, raise the temperature to 70°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com