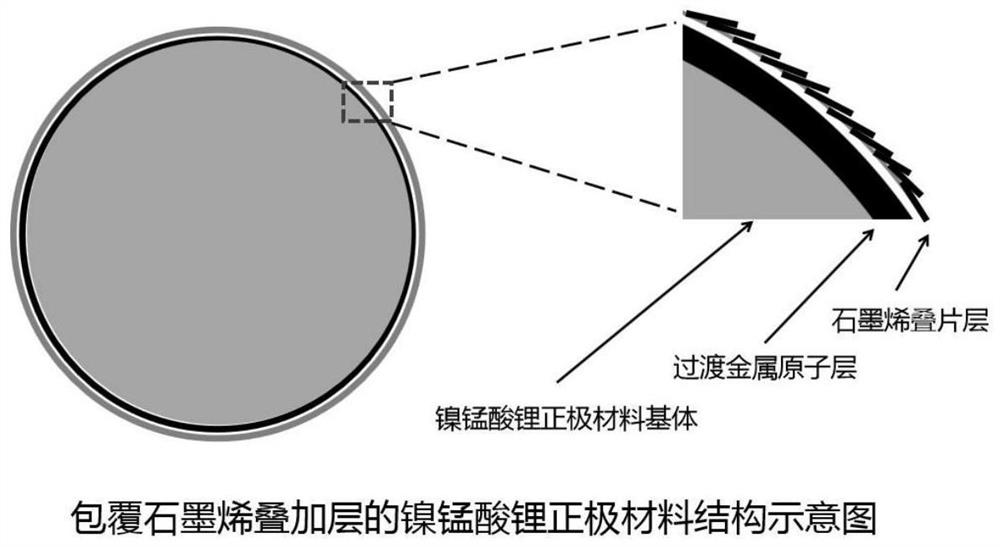

A kind of graphene-coated lithium nickel manganate cathode material and preparation method thereof

A graphene-coated, positive electrode material technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor electronic conductivity, complex process, and improvement of rate performance, so as to increase electronic conductivity and improve ionic strength. Effects of conductivity and rate performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the above-mentioned graphene-coated lithium nickel manganate positive electrode material, comprising the following steps:

[0042] A) The mixed gas formed by mixing the reducing gas and the carbon source gas is passed into the lithium nickel manganate cathode material for heating treatment;

[0043] B) raising the heating treatment temperature, adjusting the flow rate of the mixed gas, and continuing the reaction to obtain a graphene-coated lithium nickel manganate positive electrode material.

[0044] Specifically, the present invention firstly mixes the reducing gas and the carbon source gas to form a mixed gas. Wherein, the reducing gas is selected from hydrogen and / or carbon monoxide;

[0045] The carbon source gas is selected from one or more of methane, ethylene, acetylene, propane and liquefied petroleum gas.

[0046] Then, the mixed gas is passed into the lithium nickel manganate positive electrode mat...

Embodiment 1

[0059] 1) After mixing hydrogen and ethylene according to a molar ratio of 0.01:1, pass it into the heated lithium nickel manganate matrix, the flow rate of the mixed gas is 5ml / min, and the heating temperature is 250°C.

[0060] 2) After 1 hour, the heating temperature was raised to 900°C, and the flow rate of the mixed gas was adjusted to 10ml / min.

[0061] 3) After 0.5 hours, cooling and sieving to obtain the lithium nickel manganate positive electrode material of the present invention coated with the graphene superimposed layer.

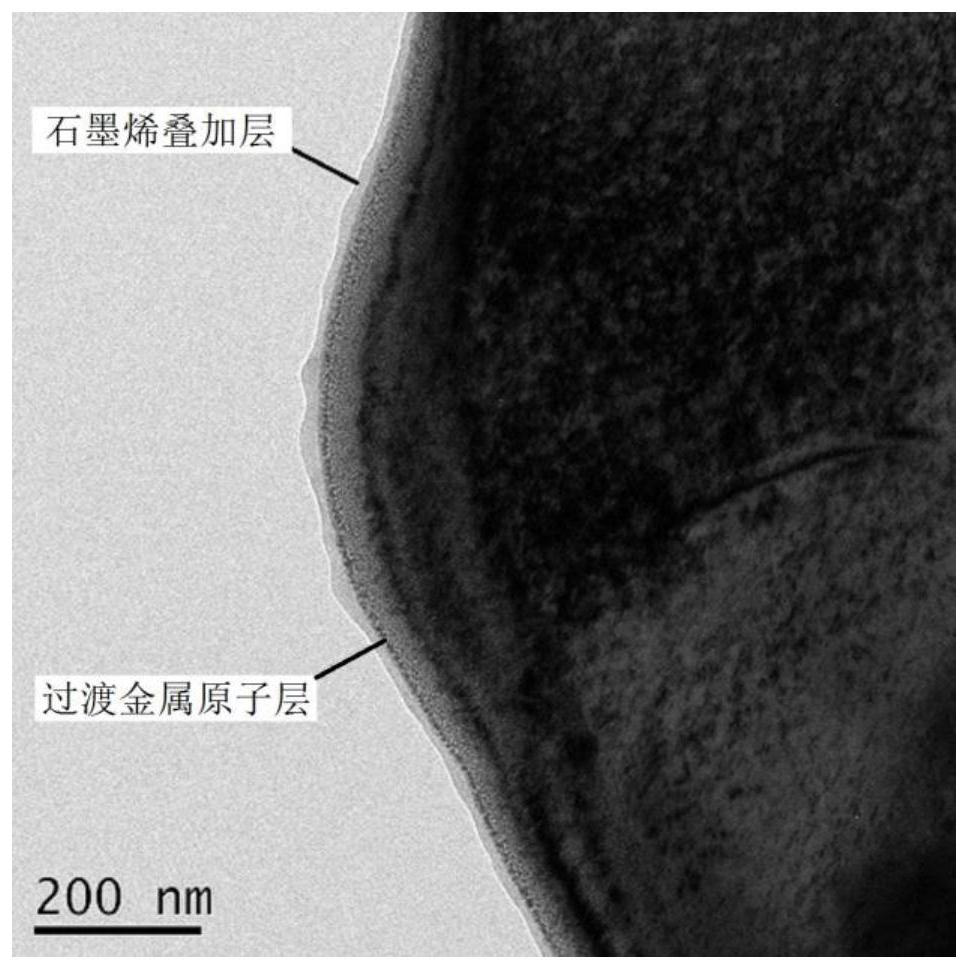

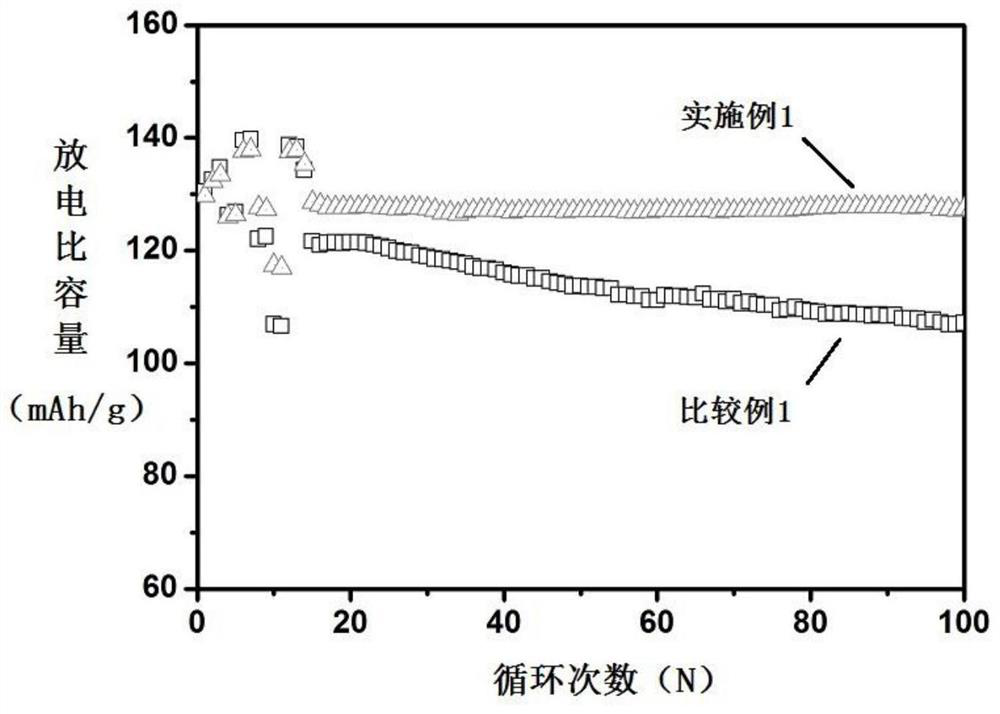

[0062] The transmission electron microscope of the lithium nickel manganate positive electrode material coated with graphene superimposed layer prepared in Example 1 is as follows: figure 2 shown, by figure 2 It can be seen that there is a transition metal atomic layer with a thickness of about 5 nm and a graphene superimposed coating layer with a thickness of about 15 nm on the outermost surface of the lithium nickel manganate cathode materia...

Embodiment 2

[0067] 1) After hydrogen and acetylene are mixed according to the molar ratio of 0.02:1, they are passed into the heated lithium nickel manganate matrix, the flow rate of the mixed gas is 8ml / min, and the heating temperature is 200°C.

[0068] 2) After 0.5 hours, the heating temperature was raised to 950°C, and the flow rate of the mixed gas was adjusted to 20ml / min.

[0069] 3) After 0.2 hours, cooling and sieving to obtain the lithium nickel manganate cathode material of the present invention coated with the graphene superimposed layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com