A kind of weight loss meal replacement nutritional powder and its production process

A production process and nutrition powder technology, which is applied in the production process field of the nutrition powder, can solve the problems that the weight loss meal replacement nutrition powder is not suitable for weight loss, low production efficiency, uneven mixing, etc., and achieve high crushing and mixing efficiency and uniform materials The effect of high stability and uniform pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The meal replacement nutrition powder is composed of the following components by weight: 200-300 parts of isolated milk protein, 30-80 parts of konjac powder, 80-180 parts of crystalline fructose, 200-300 parts of water-soluble dietary fiber, 30-60 parts of vegetable oil powder, 2-8 parts of multivitamins, 2-6 parts of zinc gluconate, 3-5 parts of calcium carbonate, 10-50 parts of psyllium husk, 10-60 parts of collagen peptide, 3-6 parts of magnesium carbonate, skimmed milk 20-50 parts of wolfberry powder, 20-50 parts of wolfberry powder, 20-60 parts of solid malt extract, 10-30 parts of jujube powder, 10-40 parts of barley powder, 10-35 parts of gorgon powder, 15-40 parts of red bean powder, 15-50 parts of yam powder;

[0067] It also includes sodium chloride, whose content is 0.5-2% of the mass sum of all the aforementioned components.

[0068] The multivitamin can be more than one combination of vitamin C, vitamin A, vitamin E, niacin, vitamin B2, pantothenic acid, ...

Embodiment 2

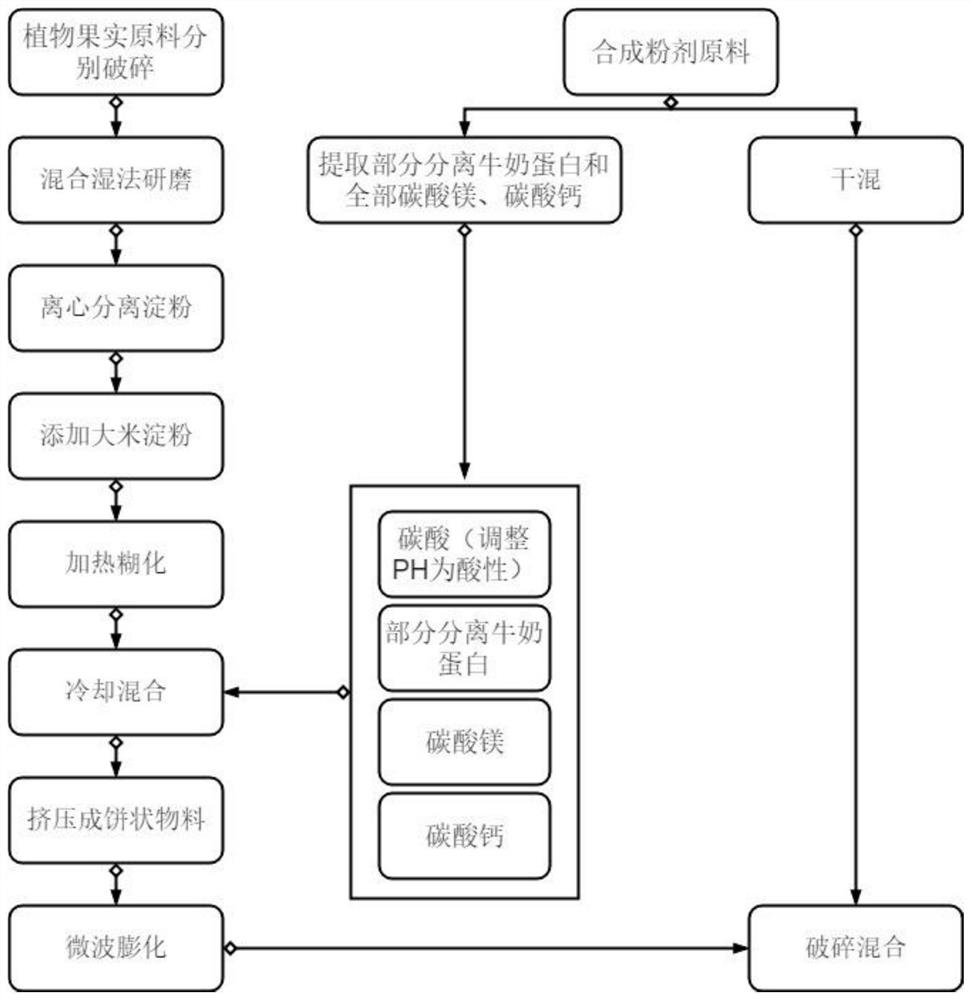

[0071] Production process:

[0072] Divide all components into plant fruit raw materials and synthetic powder raw materials; plant fruit raw materials include wolfberry, jujube, barley, gorgon, red bean, and yam; the remaining materials are included in synthetic powder raw materials, which can be block or powder. The finished product is dry and easily crushed.

[0073] Plant fruit raw materials are cleaned and sterilized separately;

[0074] The natural plant fruit raw materials in step 1 are directly mixed and then wet-ground to form a mixed slurry, the solid content of the slurry is 50-80%; the wet-ground materials are mixed more uniformly;

[0075] Add water to the slurry in step 2 to a solid content of 30-50%, and centrifuge to separate the starch from the slurry. In actual operation, after determining the solid content, adjust the two parameters of centrifugation speed and time, according to the starch content in the separated liquid It is determined that the separated ...

Embodiment 3

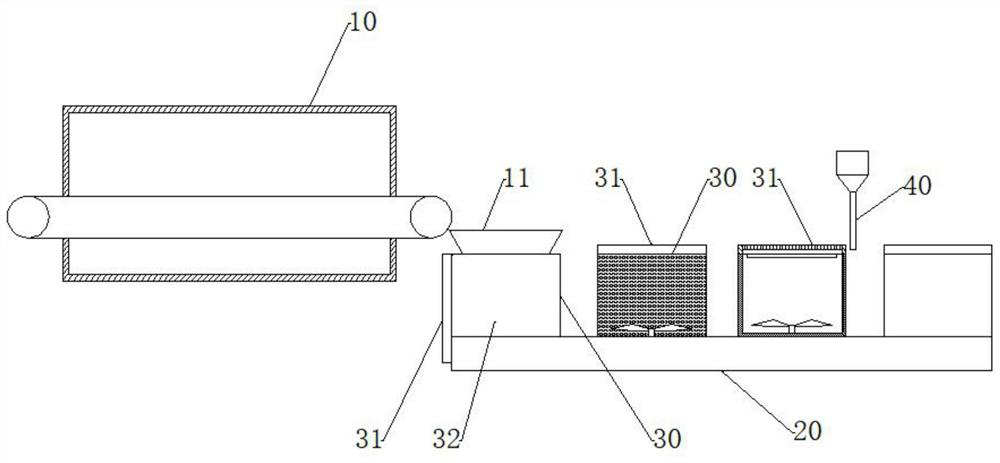

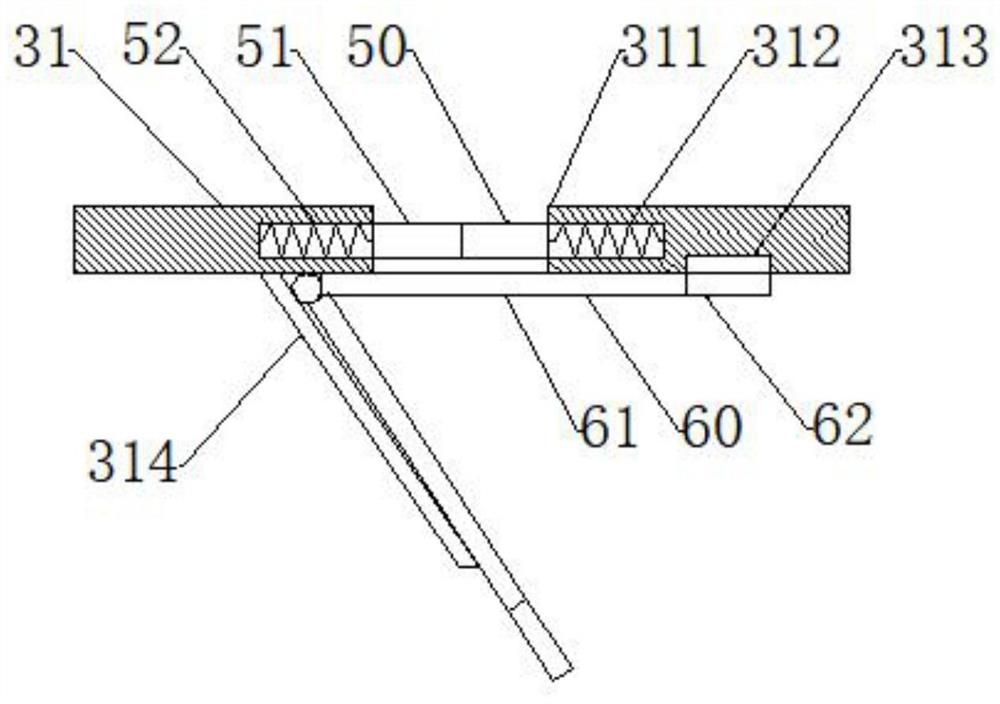

[0083] The cake-like material in step 7 can be made into small pieces, each with a diameter of 10-50cm; the microwave puffing equipment in step 8 uses a tunnel-type microwave puffing machine to continuously puff the material; A single piece of material or multiple pieces of material are crushed in multiple small crushing devices. After crushing, the synthetic powder raw materials are added to mix directly. Evenly divided. For specific equipment, see Figure 2-5 .

[0084] Provide a kind of equipment used in steps 7 to 9, including a tunnel microwave extruder 10, a turntable 20, a crushing tank 30, and a feeding pipe 40;

[0085] The tunnel microwave puffing machine 10 is used for microwave puffing the cake-shaped material extruded in step 7, and at the same time transporting the material to the next process;

[0086] The feeding end of the microwave puffing machine 10 has a feeding hopper 11;

[0087] The turntable 20 is fixed or detachably fixed evenly spaced crushing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com