Liquid catalyst for room-temperature catalytic ozonolysis as well as preparation method and application thereof

A liquid catalyst, ozone decomposition technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., to achieve the effect of low cost, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

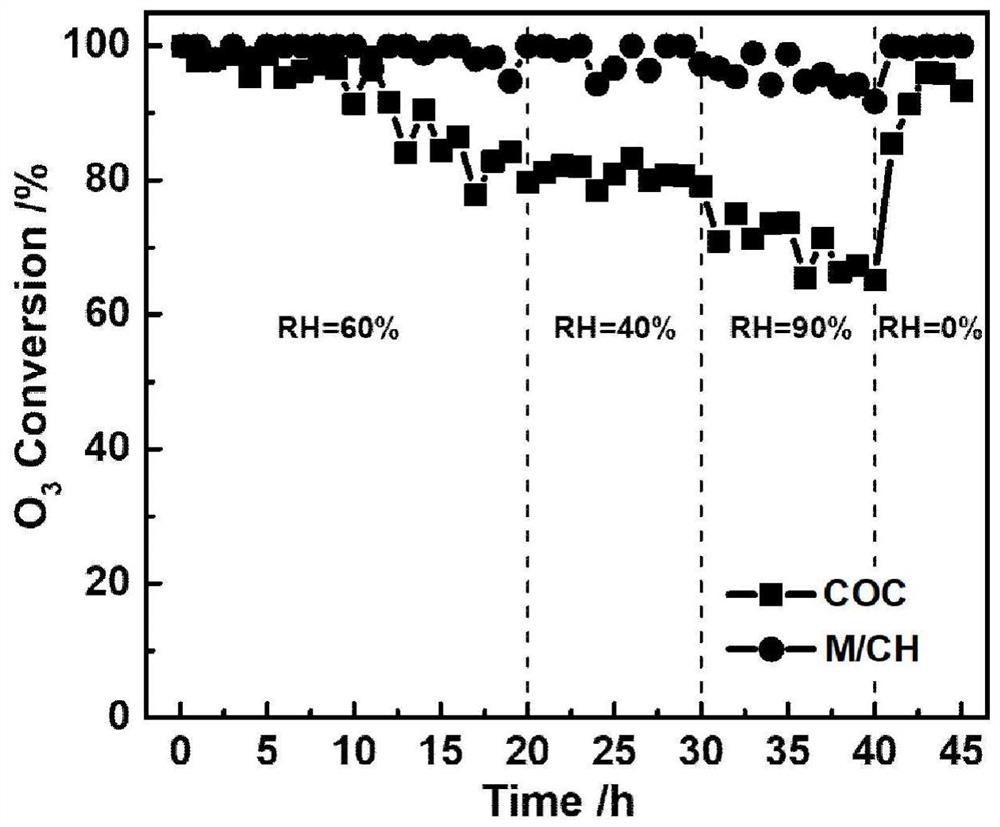

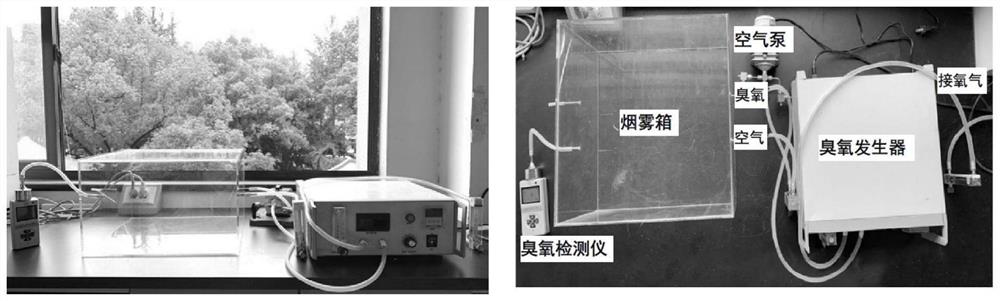

Examples

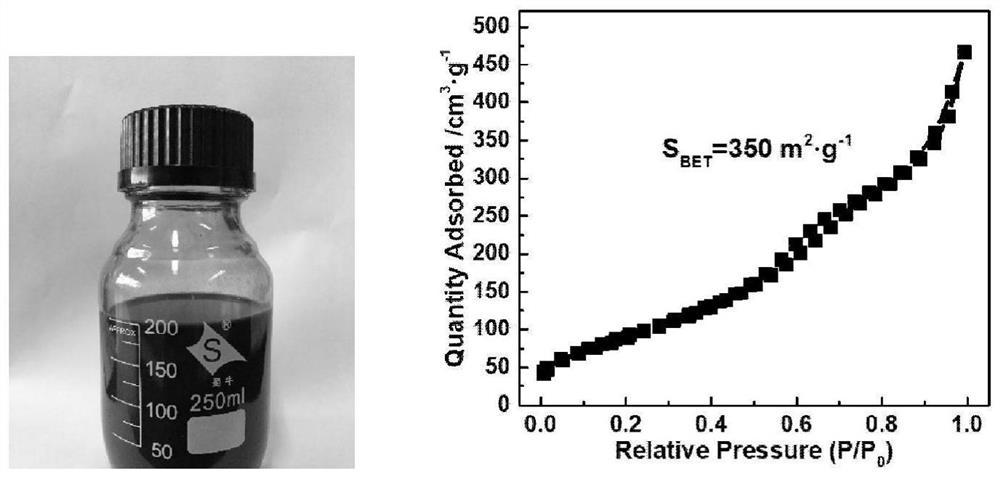

Embodiment 1

[0038] Mix 7.55g manganese sulfate with 1.46g EDTA, 2.75×10 -3 g sodium pyrophosphate plus 22.7mL water to form a solution, put it in a 70°C water bath and stir for 20min, add 37.8mL water and absolute ethanol mixture (volume ratio 1:1) after cooling and transfer to a crystallization kettle, place at 180°C Crystallize in an oven for 3 hours, and then carry out suction filtration after cooling to room temperature. Add 55mL of ethanol to the obtained solid to disperse, and obtain a concentration of 5×10 -2 g / mL manganese oxide room temperature ozonolysis liquid catalyst.

Embodiment 2

[0040] 6.30g manganese chloride, 10.10g ferric nitrate and 6.75g oxalic acid, 8.29×10 -2 g sodium tripolyphosphate plus 49.2mL water to form a solution, placed in a 90°C water bath and stirred for 30min, after cooling, added 164mL water and ethylene glycol mixture (volume ratio 1:1) and transferred to a crystallization kettle, placed at 120°C Crystallize in an oven for 8 hours, and after cooling to room temperature, carry out suction filtration, add 4140mL of water to the obtained solid to disperse, and obtain a concentration of 1×10 -3 g / mL ferromanganese binary composite oxide liquid catalyst for ozonolysis at room temperature.

Embodiment 3

[0042] 14.32g manganese nitrate, 8.08g ferric nitrate, 1.09g cerium nitrate and 12.0g citric acid, 7.32×10 -2g sodium hexametaphosphate plus 2.3mL water to form a solution, add 164.4mL of absolute ethanol and transfer to a crystallization kettle, place in a 140°C oven for crystallization for 4 hours, cool to room temperature and perform suction filtration, and add 180mL of acrylic acid to the obtained solid Alcohol is dispersed to obtain a concentration of 2×10 -2 g / mL manganese-iron-cerium ternary composite oxide liquid catalyst for ozonolysis at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com