A kind of method for preparing methyl nitrite from nitric acid

A technology of methyl nitrite and nitric acid, applied in the direction of nitrite preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of dilute nitric acid pollution, large environmental impact, difficult to handle, etc. Good stability, high activity and selectivity, the effect of solving dilute nitric acid pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

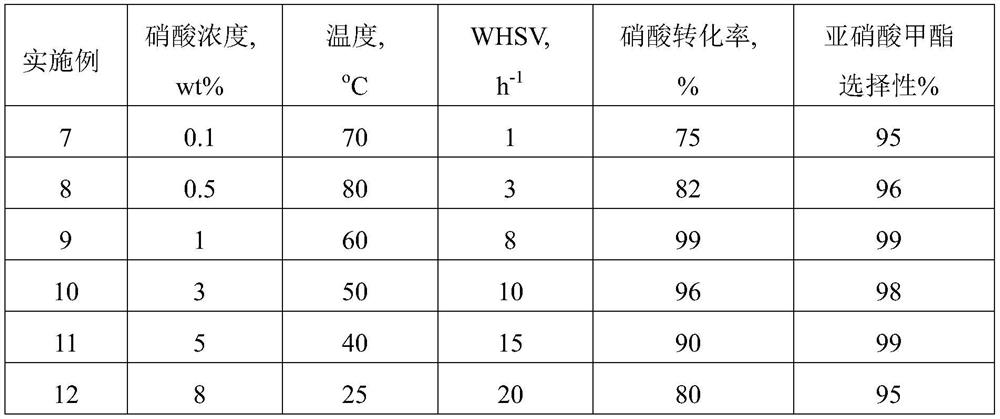

Examples

Embodiment 1

[0026] Add 50g of 10-20 mesh silica, 0.2g of vinylpyrrolidone-vinyl acetate copolymer, and 100g of ethyl acetate into a 250ml reaction flask, keep a constant temperature water bath at 70°C, stir mechanically, add 10g of vinylpyrrolidone and 75mg of an initiator coupler. Nitrogen bisisobutyronitrile was reacted under nitrogen protection for 6 hours, cooled to room temperature and filtered. The obtained solid was dried at 100 °C for 24 hours and then passed through a 10-20 mesh sieve to obtain 59 g of a nitrogen-containing organic polymer-coated silicon-containing inorganic compound, namely a polymer Vinylpyrrolidone-coated silica, denoted as PVP@SiO 2 .

[0027] Take 5g PVP@SiO 2 , add 5ml of ruthenium trichloride aqueous solution prepared with 0.5g of hydrated ruthenium trichloride, stir evenly, let stand for 24h, dry at 100°C for 12h, N 2 It was calcined at 450 °C for 3 h under the protection to obtain a core-shell catalyst, that is, a nitrogen-doped carbon-coated core-shel...

Embodiment 2~6

[0030] The specific practices of Examples 2 to 6 are similar to those of Example 1, except that the prepared nitrogen-doped carbon-coated core-shell supported metal catalysts have silicon dioxide or silicon carbide as the core and ruthenium or gold as the metal.

Embodiment 2

[0032] The difference from Example 1 is that 50 g of 10-20 mesh silicon carbide, 0.2 g of vinylpyrrolidone-vinyl acetate copolymer, and 100 g of ethyl acetate were added to a 250 ml reaction flask. Finally, a nitrogen-doped carbon-coated core-shell silicon carbide-supported ruthenium catalyst was obtained, denoted as Ru-N-C@SiC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com