Method for recovering lithium from lithium-containing wastewater

A technology for recovering lithium and waste water, applied in the field of lithium recovery, can solve problems such as high investment cost, equipment corrosion, difficult stripping, etc., and achieve the effect of short process flow, low equipment investment and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for reclaiming lithium from lithium-containing wastewater, comprising the steps of:

[0033] (1) Adopt sulfuric acid to adjust the pH of lithium-containing waste water to be 2.0, detect wherein Li + =3.7g / L, Na + =21g / L;

[0034] (2) 40% C272 (bis(2,4,4-trimethylpentyl) phosphonic acid), 20% TBP (tributyl phosphate) and 40% sulfonated kerosene are formulated into an organic phase by mass percentage, Take 100mL of the organic phase and saponify it with 5mol / L sodium hydroxide according to 1.4 times the lithium concentration in the lithium-containing wastewater. After saponification, no phase separation is required. Place 100mL of the organic phase after saponification and 100mL of the lithium-containing wastewater into a separatory funnel. Vibrate at a rotation speed of 240 rpm, extract at a temperature of 40° C. for 4 minutes, and stand still to separate phases to obtain an organic phase containing lithium ions and a raffinate.

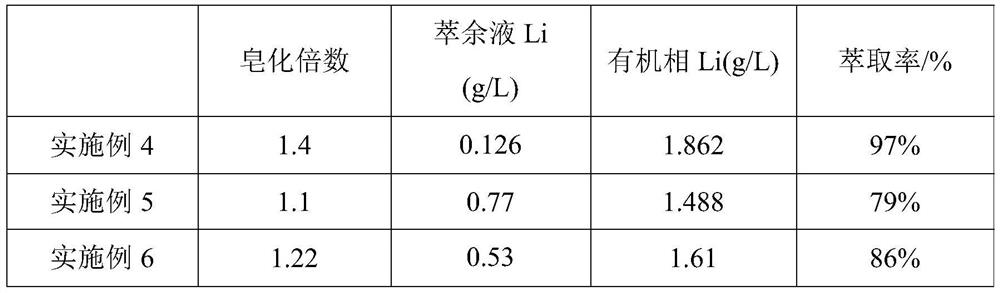

[0035] The detection results...

Embodiment 2

[0037] A method for reclaiming lithium from lithium-containing wastewater, comprising the steps of:

[0038] (1) Adopt sulfuric acid to adjust the pH of lithium-containing waste water to be 4.0, detect wherein Li + =3.7g / L, Na + =21g / L;

[0039] (2) 40% C272 (bis(2,4,4-trimethylpentyl) phosphonic acid), 20% TBP (tributyl phosphate) and 40% sulfonated kerosene are formulated into an organic phase by mass percentage, Take 100mL of the organic phase and saponify it with 5mol / L sodium hydroxide according to 1.4 times the lithium concentration in the lithium-containing wastewater. After saponification, no phase separation is required. Take 100mL of the saponified organic phase and 100mL of the lithium-containing wastewater and place them in a separatory funnel. Shake at a rotation speed of 240 rpm, extract at a temperature of 40° C. for 4 minutes, and stand still to separate phases to obtain an organic phase containing lithium ions and a raffinate.

[0040] The detection results...

Embodiment 3

[0042] A method for reclaiming lithium from lithium-containing wastewater, comprising the steps of:

[0043] (1) Sulfuric acid is used to adjust the pH of lithium-containing wastewater to 6.0, and Li + =3.7g / L, Na + =21g / L;

[0044] (2) 40% C272 (two (2,4,4-trimethylpentyl) phosphonic acid), 20% TBP (tributyl phosphate) and 40% sulfonated kerosene by volume percentage are made into an organic phase, Take 100mL of the organic phase and saponify it with 5mol / L sodium hydroxide according to 1.4 times the lithium concentration in the lithium-containing wastewater. Shake at 240rpm, extract at 40°C for 4min, and stand still to separate the phases to obtain an organic phase containing lithium ions and a raffinate.

[0045] The detection results of lithium content in the raffinate are shown in Table 1, and the extraction rate of lithium is 58.6%.

[0046] Table 1 Extraction of lithium-containing wastewater by C272 and TBP combined extractant at different pH

[0047] Wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com