Urethane resin and polishing pad using polyrotaxane

A urethane, polyrotaxane technology, applied in the field of polishing pads, to achieve the effects of low hysteresis loss, low scratch resistance, and excellent polishing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

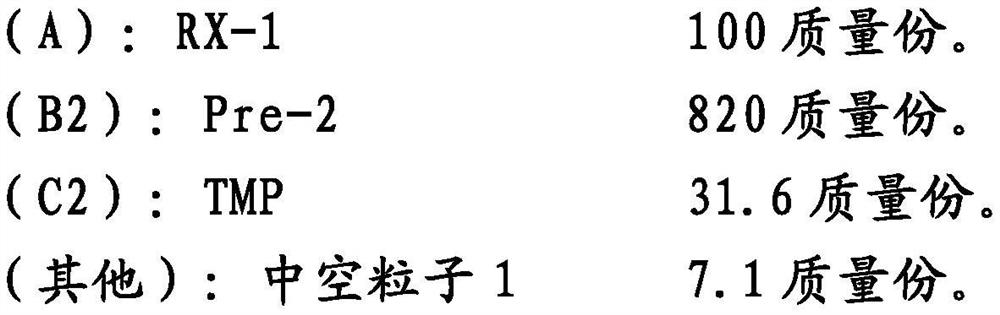

[0308] Next, the present invention will be described in detail using examples and comparative examples, but the present invention is not limited to these examples. In the following examples and comparative examples, evaluation methods and the like are as follows.

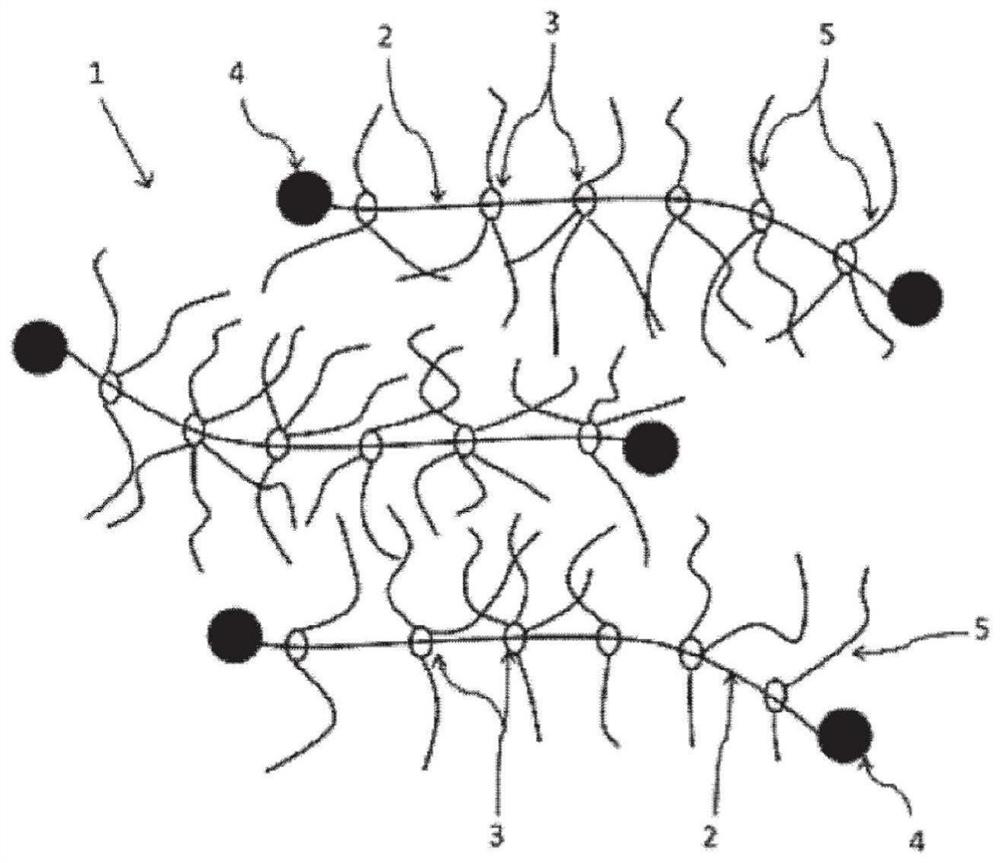

[0309] (Polyrotaxane (A) used)

[0310] RX-1: a polyrotaxane having a side chain having a hydroxyl group, an average molecular weight of about 350, a weight average molecular weight of 200,000, and a hydroxyl value of 87 mgKOH / g.

[0311] RX-2: A polyrotaxane having a side chain having a hydroxyl group, having a molecular weight average of about 650, a weight average molecular weight of 350,000, and a hydroxyl value of 55 mgKOH / g.

[0312] From the value of the hydroxyl value, the total number of moles (ns2) of active hydrogen-containing groups in the side chain of the polyrotaxane (A) can be calculated

[0313] (Molecular weight measurement: gel permeation chromatography (GPC measurement))

[0314] For the measu...

manufacture example

[0318] Manufacturing example (manufacturing of RX-1)

[0319] (1-1) Preparation of PEG-COOH:

[0320] Linear polyethylene glycol (PEG) with a molecular weight of 10,000 was prepared as a polymer for forming the shaft molecule.

[0321] Prepare the following prescriptions:

[0322] PEG 10g

[0323] TEMPO (2,2,6,6-tetramethyl-1-piperidinyloxy radical) 100mg

[0325] The ingredients were dissolved in 100 mL of water. To this solution, 5 mL of a commercially available sodium hypochlorite aqueous solution (5% available chlorine concentration) was added, followed by stirring at room temperature for 10 minutes. Then, ethanol was added in a range of up to 5 mL to terminate the reaction. Then, 50 mL of dichloromethane was used for extraction, and then the dichloromethane was distilled off, dissolved in 250 mL of ethanol, and then reprecipitated at a temperature of -4° C. for 12 hours to recover dry PEG-COOH.

[0326] (1-2) Preparation of polyrotaxane:...

manufacture example P

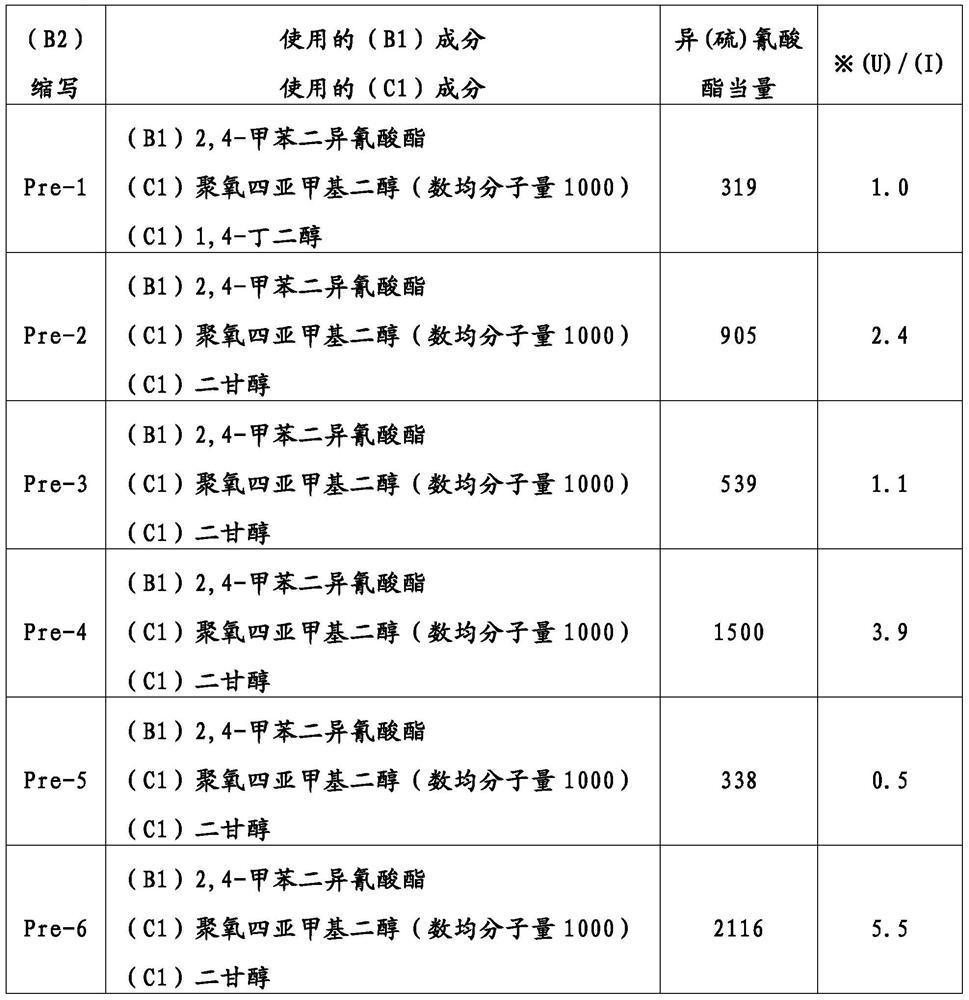

[0363] Production example of production example Pre-1

[0364] In a flask equipped with a nitrogen introduction tube, a thermometer, and a stirrer, 50 g of 2,4-toluene diisocyanate, 32 g of polyoxytetramethylene glycol (number average molecular weight: 1000) and 1,4-butylene were mixed under a nitrogen atmosphere. 10 g of diol was reacted at 80°C for 8 hours to obtain an isocyanate-terminated urethane prepolymer having an iso(thio)cyanate equivalent of 319 (pre-1 was obtained).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com