Lightweight high-strength concrete and preparation method thereof

A concrete and high-strength technology, applied in the field of concrete, can solve the problems of low concrete strength and heavy quality, and achieve the effects of preventing concrete cracking, increasing compressive and flexural strength, and improving anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] see Figure 1-10 As shown, the present embodiment is a preparation method of lightweight high-strength concrete, and the lightweight high-strength concrete includes the following components in parts by weight:

[0043] 8 parts of activated silica, 5 parts of activated alumina, 35 parts of aluminum silicate ceramic fiber, 30 parts of modified fly ash, 60 parts of shell powder, 2 parts of carbon nanotubes, 5 parts of nano silicon dioxide, fatty alcohol polyoxygen 1 part of vinyl ether, 70 parts of cement, 50 parts of gravel, 20 parts of ferric oxide, 70 parts of water, 20 parts of additives and 130 parts of sand;

[0044] The lightweight high-strength concrete is prepared by the following steps:

[0045] Step 1, preparation auxiliary agent:

[0046] S11: Weigh the following raw materials by weight: 5 parts of steel fiber, 2 parts of methacrylate, 2 parts of isophorone diisocyanate, 4 parts of bisphenol A epoxy resin, 3 parts of magnesium oxide, 4 parts of ethyl acrylate...

Embodiment 2

[0057] see Figure 1-10 As shown, the present embodiment is a preparation method of lightweight high-strength concrete, and the lightweight high-strength concrete includes the following components in parts by weight:

[0058] 12 parts of activated silica, 7 parts of activated alumina, 40 parts of aluminum silicate ceramic fiber, 40 parts of modified fly ash, 70 parts of shell powder, 3 parts of carbon nanotubes, 7 parts of nano-silica, fatty alcohol polyoxygen 2 parts of vinyl ether, 80 parts of cement, 70 parts of gravel, 30 parts of ferric oxide, 90 parts of water, 30 parts of additives and 160 parts of sand;

[0059] The lightweight high-strength concrete is prepared by the following steps:

[0060] Step 1, preparation auxiliary agent:

[0061] S11: Weigh the following raw materials by weight: 6 parts of steel fiber, 3 parts of methacrylate, 3 parts of isophorone diisocyanate, 5 parts of bisphenol A epoxy resin, 4 parts of magnesium oxide, 5 parts of ethyl acrylate , 0.7...

Embodiment 3

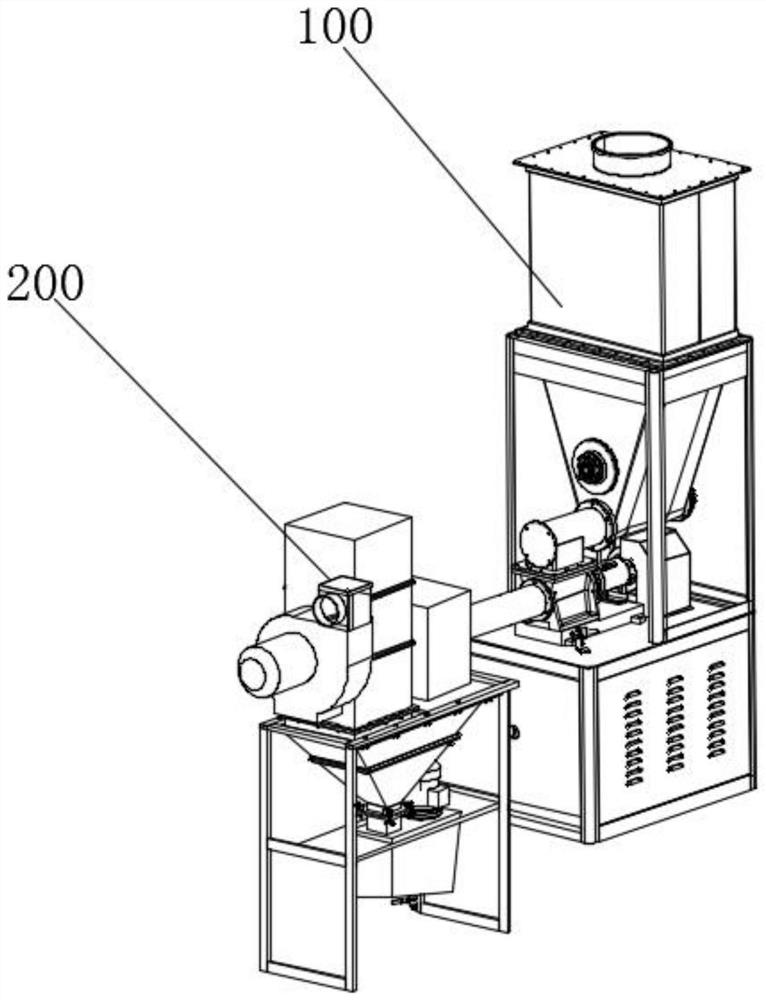

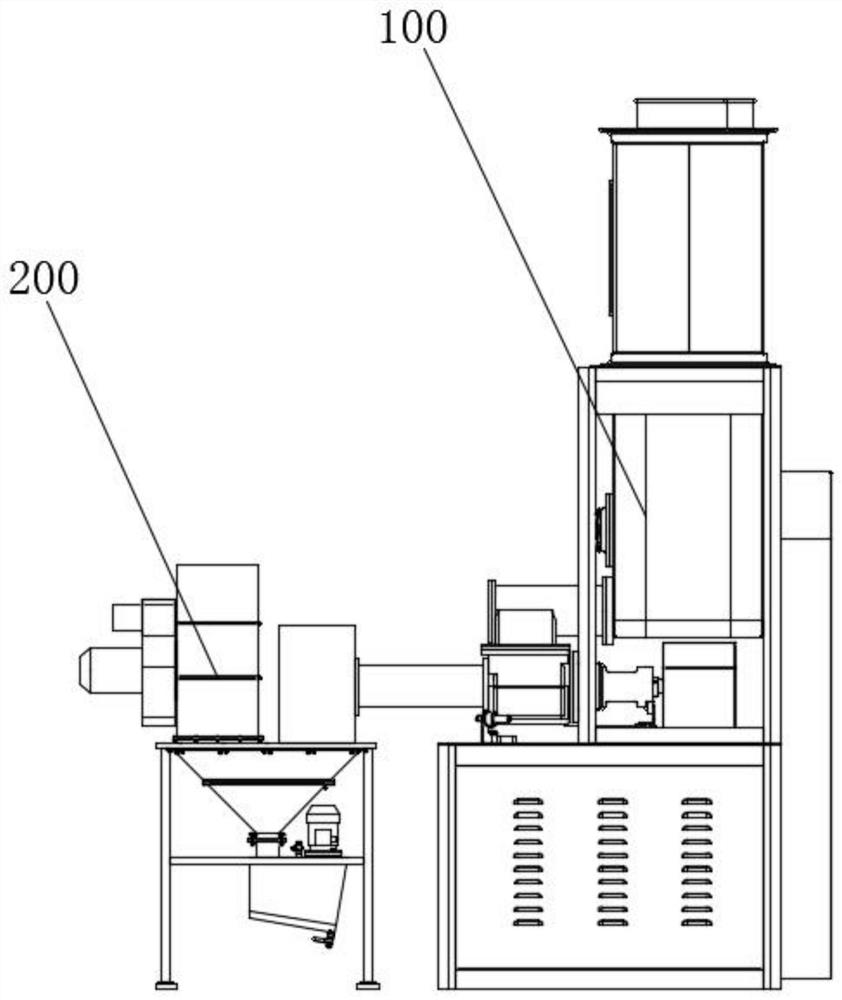

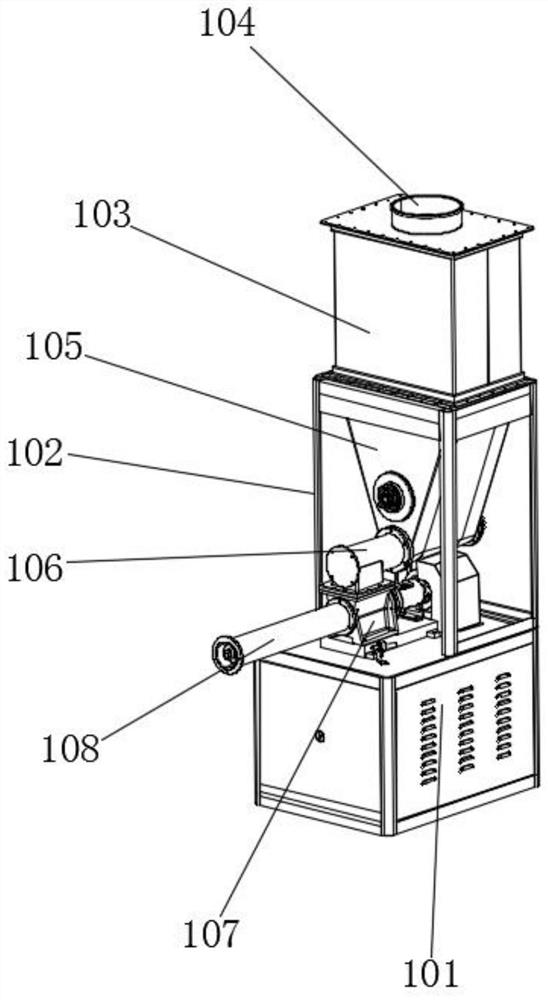

[0072] see Figure 1-10 As shown, the crushing and refining device in this embodiment includes a crushing mechanism 100 and a screening mechanism 200, and the crushing mechanism 100 is connected to the screening mechanism 200;

[0073] Wherein, the crushing mechanism 100 includes a mounting box 101, a first mounting frame 102, a storage box 103, a feed port 104, a crushing bin 105, a first conveying pipe 106, a mounting seat 107, a second conveying pipe 108, a transmission box 109, the first driving motor 110, the first driving pulley 111, the first driven pulley 112, the second driving motor 113, the second driving pulley 114, the second driven pulley 115, the driving sprocket 116, from Moving sprocket 117, the first transmission shaft 118, the first shearing blade 119, the second transmission shaft 120, the cutting knife 121, the second shearing blade 122, the third transmission shaft 123, the stirring shaft 124, the installation box The top of 101 is equipped with the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com