Preparation method of amphoteric polyacrylic acid retanning agent

A technology of polyacrylic acid retanning agent and acrylic acid, which is applied in the fields of small hide/big hide/leather/fur treatment, tanning treatment, small hide/big hide/leather skin/fur chemical treatment, etc., to achieve good filling performance and combination High fastness and the effect of improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

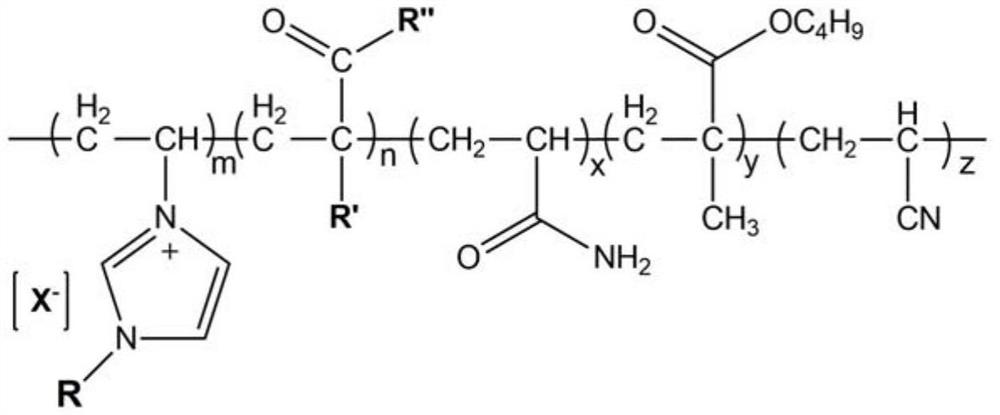

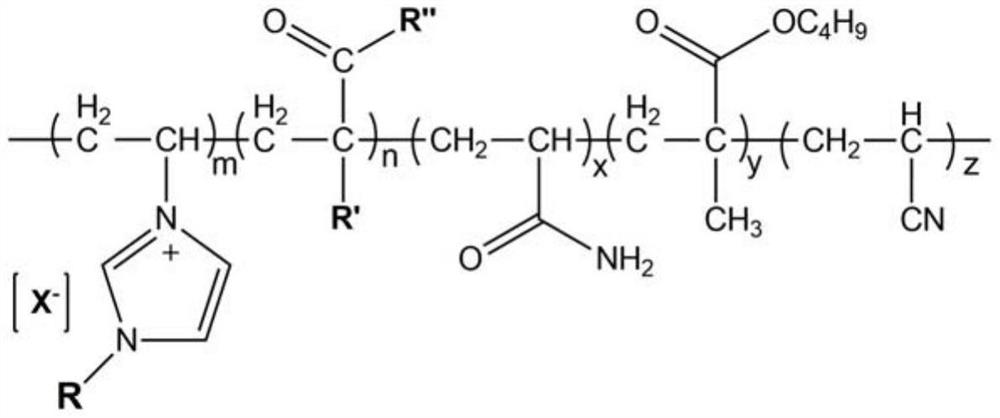

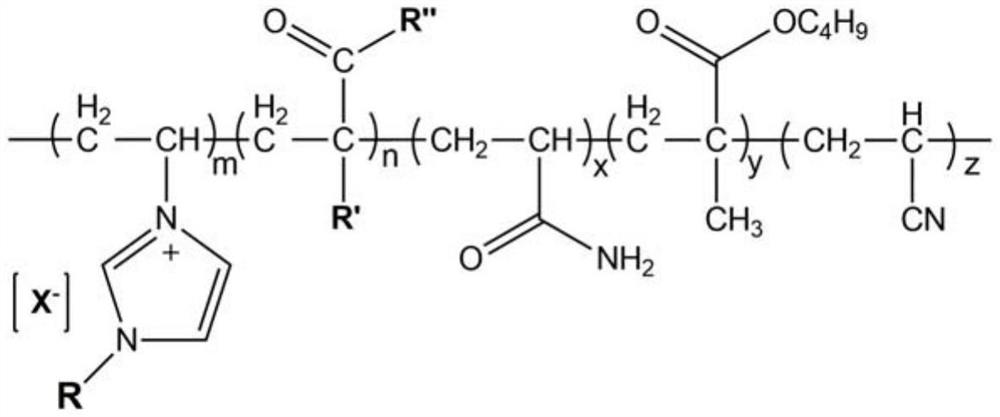

[0026] A preparation method of amphoteric polyacrylic acid retanning agent, it comprises the following steps:

[0027] S1: Provide monomers for preparing the amphoteric polyacrylic acid retanning agent, the monomers include the following components in parts by weight: Vinyl ionic liquid monomer: 12-35 parts, one of acrylic acid and methacrylic acid One or two: 15-45 parts, acrylamide: 10-25 parts, butyl methacrylate: 15-22 parts, and acrylonitrile: 12-18 parts;

[0028] S2: Stir and mix the vinyl ionic liquid monomer, acrylonitrile, and butyl methacrylate at a certain temperature to obtain a uniform mixed solution A;

[0029] S3: dissolving one or both of acrylic acid and methacrylic acid and acrylamide in a certain amount of pure water to obtain a uniform aqueous solution B;

[0030] S4: Add the mixed solution A and the aqueous solution B into the reaction kettle, and mix them evenly under nitrogen;

[0031] S5: Provide initiators, chain transfer agents, and neutralizing ag...

Embodiment 1

[0044] Weigh 16g of vinyl ionic liquid 1-vinyl-3-butylimidazole bromide, 12g of acrylonitrile, and 17g of butyl methacrylate into the reaction kettle, and stir at 30°C for 1 hour until a uniform mixed solution is obtained A;

[0045] Weigh 35g of acrylic acid and 20g of acrylamide into 165g of water, stir at room temperature for 1 hour to obtain a uniform aqueous solution B;

[0046] Aqueous solution B is joined in the reactor that mixed solution A is housed, and under the condition of nitrogen bubble, continue to stir for 30 minutes, then add 0.5g initiator potassium persulfate, 2g chain transfer agent dodecyl mercaptan , stir and mix evenly, increase the reaction temperature to 60°C, and keep the temperature for 18 hours to ensure complete polymerization of monomers. Remove the heat source, cool the reaction kettle to room temperature, and adjust the pH value of the product to 6.5 to 7.5 with 10% sodium hydroxide solution to obtain the amphoteric polypropylene retanning age...

Embodiment 2

[0049] Weigh 25g of vinyl ionic liquid 1-vinyl-3-methylimidazole chloride, 15g of acrylonitrile, 20g of butyl methacrylate into the reaction kettle, stir at 30°C for 1 hour until a uniform mixed solution is obtained A;

[0050] Weigh 25g of acrylic acid and 15g of acrylamide into 100g of water, stir at room temperature for 1 hour to obtain a uniform aqueous solution B;

[0051] The aqueous solution B was added to the reaction kettle equipped with the mixed solution A, and under the condition of nitrogen bubbling, the stirring was continued for 30 minutes, followed by adding 1.0 g of the initiator ammonium persulfate, 3.0 g of the chain transfer agent cetyl sulfide Alcohol, stir and mix evenly, increase the reaction temperature to 60°C, and keep it warm for 12 hours to ensure complete polymerization of the monomer. Remove the heat source, cool the reaction kettle to room temperature, and adjust the pH value of the product to 6.5 to 7.5 with 30% ammonia water to obtain the amph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com