A kind of synthetic method and equipment for tetramethylammonium hydroxide

A technology of tetramethylammonium hydroxide and synthesis method, which is applied in the direction of electrolytic components, electrodes, electrolytic organic production, etc., can solve the problems of short service life of graphite anode and low efficiency of electrolytic current, and achieve improved mechanical strength and good current Efficiency, the effect of improving the current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

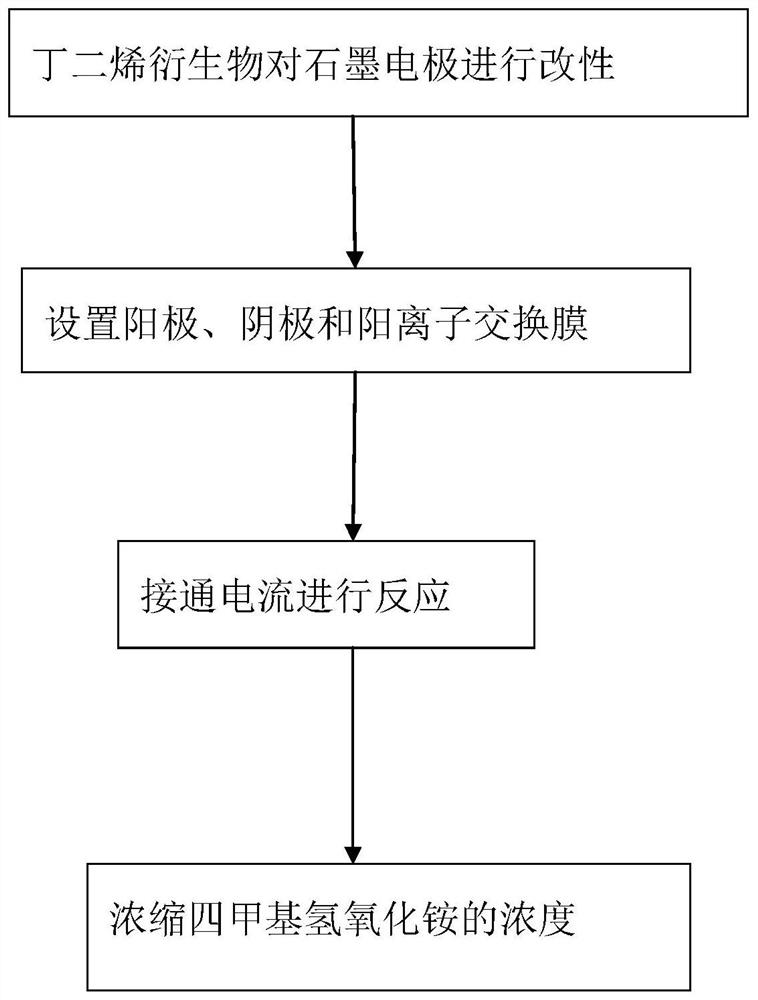

[0031] Such as figure 1 Shown, a kind of synthetic method for tetramethylammonium hydroxide comprises the following steps:

[0032] (1) butadiene derivatives are dissolved in an organic solvent to prepare an electrode electrolyte, a graphite electrode is used as a reaction electrode, platinum is used as a counter electrode, and a silver / silver chloride electrode is used as a reference electrode and put into the electrode electrolyte, Power on at -0.3V (vs.Ag / Ag+) for polymerization. After the reaction is over, a yellow film is formed on the surface of the graphite electrode to obtain a modified graphite electrode. Take it out and dry it, and place it in the anode chamber;

[0033] (2) The anode chamber and the cathode chamber are separated by a cation exchange membrane, and a cathode is placed in the cathode chamber;

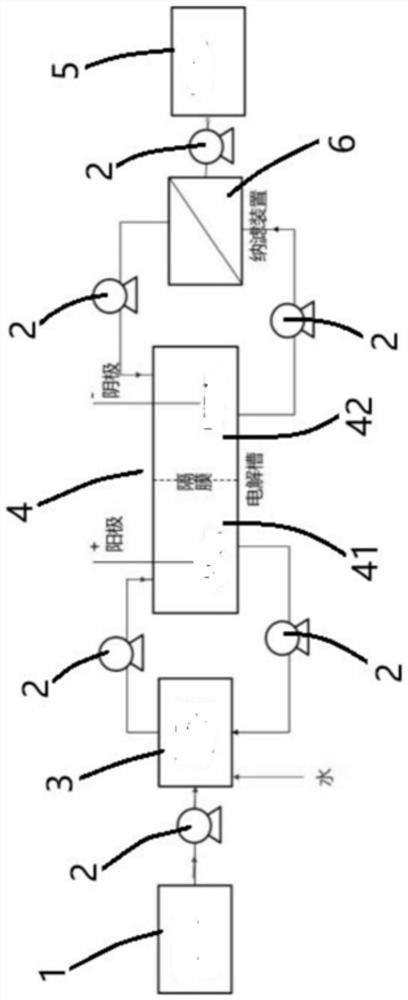

[0034] (3) Connect the current between the modified graphite electrode and the cathode, use tetramethylammonium chloride solution as raw material, pump it into...

Embodiment 1

[0050] Dissolve 1,1,4,4-tetrachloro,2,3-difluorobutadiene and lithium tetrafluoroborate in tetrahydrofuran to prepare electrode electrolyte, use graphite electrode as reaction electrode, platinum as counter electrode, silver / The silver chloride electrode is used as a reference electrode and placed in the electrode electrolyte, and is energized at -0.3V (vs.Ag / Ag+) for 1 hour for polymerization. After the reaction is completed, a yellow film is formed on the surface of the graphite electrode to obtain a modified graphite electrode. , take it out and dry it, and place it in the anode chamber.

[0051] A stainless steel plate is placed in the cathode chamber as the cathode, and the anode chamber and the cathode chamber are separated by a cation exchange membrane. Connect the current between the modified graphite electrode and the cathode, use tetramethylammonium chloride solution as the raw material, pump it into the anode chamber through the anolyte raw material tank and the an...

Embodiment 2

[0054] Except that 1,1,4,4-tetrachloro,2,3-difluorobutadiene was replaced by hexachlorobutadiene, the rest was the same as that of Example 1.

[0055] During this synthesis process, the current efficiency of electrolysis was 93.0%, and the lifetime of the modified graphite electrode was 91 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com