Method for preparing idebebone and microcrystalline cellulose composite carrier and cosmetic

A technology of microcrystalline cellulose and idebenone, applied in cosmetics, cosmetic preparations, medical preparations containing active ingredients, etc., can solve the problems of difficult loading and release, achieve excellent biological safety, reduce Irritant, good biocompatibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a preparation method of idebenone and microcrystalline cellulose composite carrier, comprising the following steps:

[0036] Step 1, taking microcrystalline cellulose powder and dispersing it in an aqueous solution to form a suspension containing microcrystalline cellulose particles;

[0037] Specifically, the microcrystalline cellulose powder is dispersed in an aqueous solution using ultrasonic waves, the mass concentration of the microcrystalline cellulose is 1%-5%, and shear dispersion is performed at 300rpm-500rpm to form a uniform suspension.

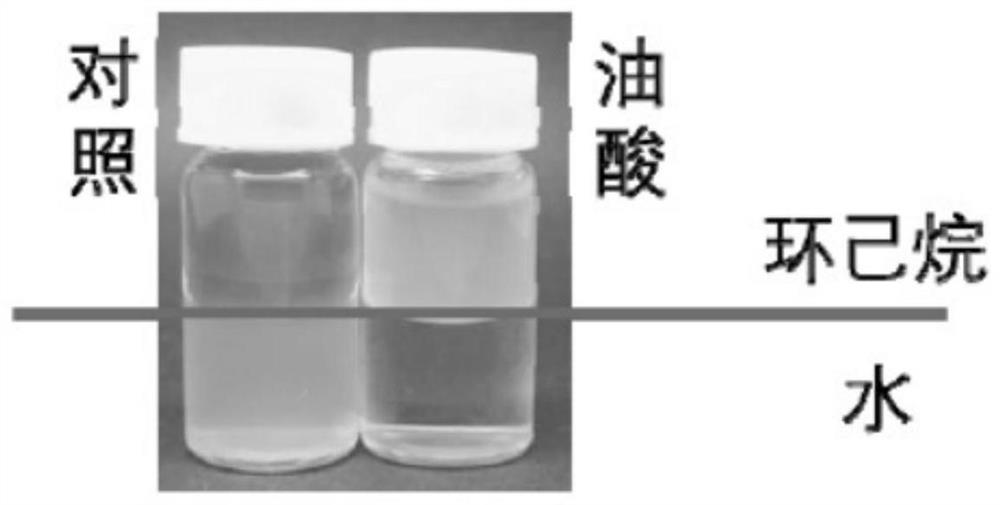

[0038] Step 2. Add oleic acid ethanol solution dropwise to the suspension, stir and mix the surface of microcrystalline cellulose particles with oleic acid, wash and centrifuge to obtain oleic acid-coated microcrystalline cellulose particles;

[0039] Specifically, the suspension needs to be heated to 60°C, and then 0.5%-2% by mass percentage of oleic acid ethanol solution is added dropwise, stirred fo...

Embodiment 1

[0044] The microcrystalline cellulose particle of embodiment 1 oleic acid modification

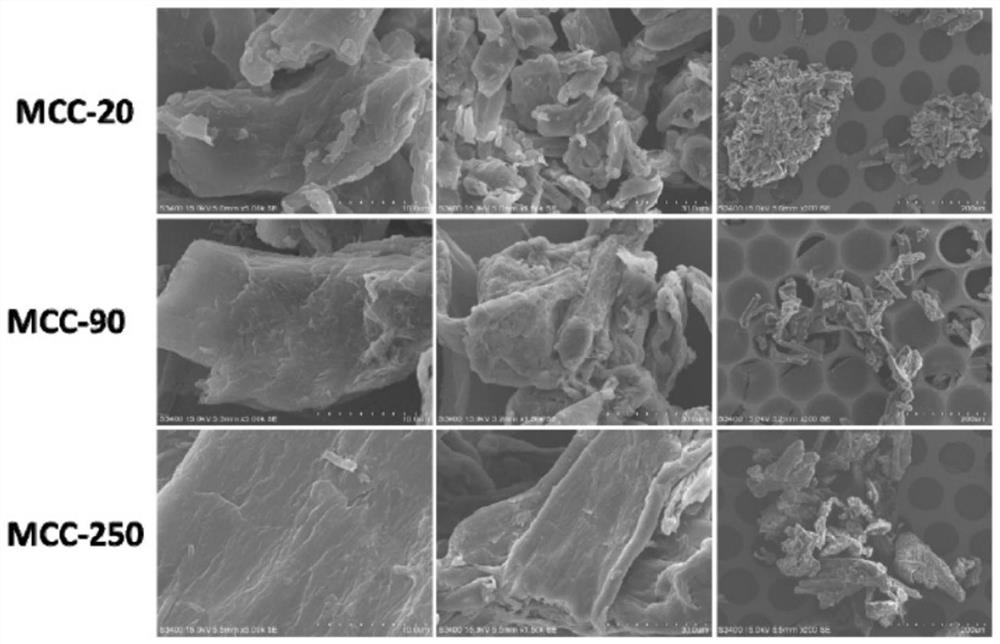

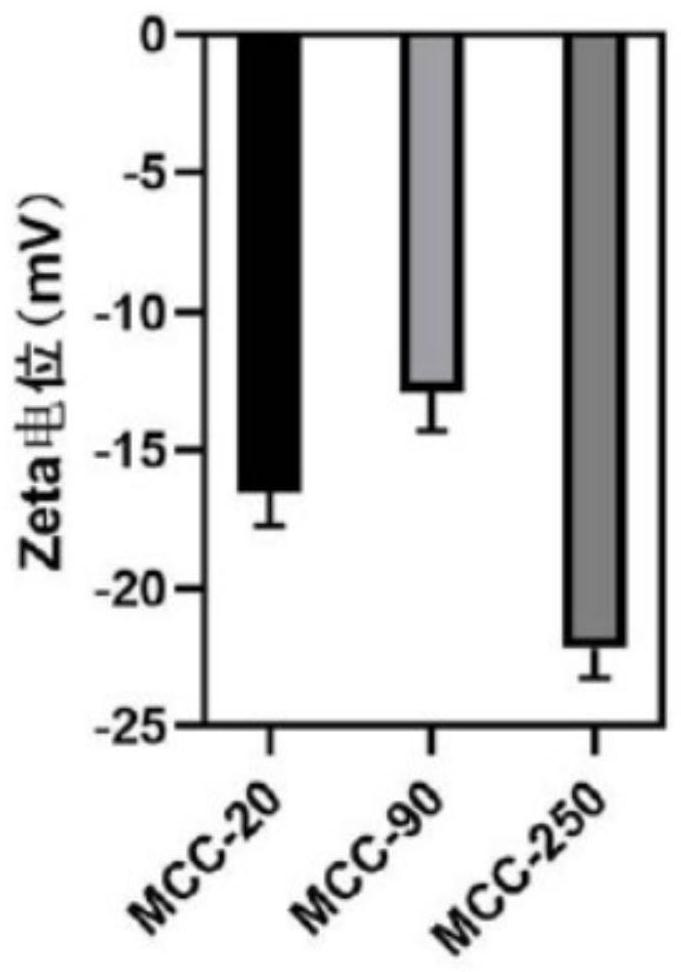

[0045] 1) Weigh three solid microcrystalline cellulose powders (MCC-20, MCC-90, MCC-250) with different particle sizes, and disperse them in the aqueous solution so that the final mass concentration is between 5%, ultrasonically disperse Finally, shear and disperse at 300rpm-500rpm to form a uniform suspension.

[0046] 2) Heat the suspension to 60°C, add 2% mass percent oleic acid ethanol solution (volume ratio 1:1), and add it dropwise to the suspension, stir for 1 hour, and wash with deionized water after adsorption equilibrium The obtained oleic acid-modified microcrystalline cellulose particles were collected by centrifugation after repeated 5 times and dried.

[0047] Microcrystalline cellulose itself has a certain adsorption capacity. By introducing oleic acid, oleic acid can be adsorbed and combined with the surface of microcrystalline cellulose, thereby forming microcrystalline ...

Embodiment 2

[0056] Determination of adsorption capacity of microcrystalline cellulose microparticles modified by embodiment 2 oleic acid

[0057] 1) Select 20 micron microcrystalline cellulose MCC-20 as the carrier, disperse it in the aqueous solution so that the final mass concentration is between 5%, after ultrasonic dispersion, shear and disperse at 300rpm-500rpm to form a uniform suspension;

[0058] 2) Heating the suspension to 60°C, adding 2% mass percent oleic acid ethanol solution (volume ratio 1:1), and adding it dropwise to the microcrystalline cellulose suspension, and stirring for 1 hour. After adsorption equilibrium, the obtained oleic acid-modified microcrystalline cellulose particles were washed with deionized water, repeated 5 times, collected by centrifugation and dried;

[0059] 3) Disperse the oleic acid-modified particles in an ethanol solution, introduce idebenone at 10 mg / mL, load for 72 hours, and centrifuge and dry to obtain the idebenone / microcrystalline cellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com