Catalyst for hydrogen production from methane steam reforming and preparation method and application thereof

A methane water vapor, reforming hydrogen production technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of affecting the activity and stability of methane water vapor and other problems, to achieve the effects of inhibiting the formation of sintering and carbon deposits, increasing surface oxygen vacancies, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

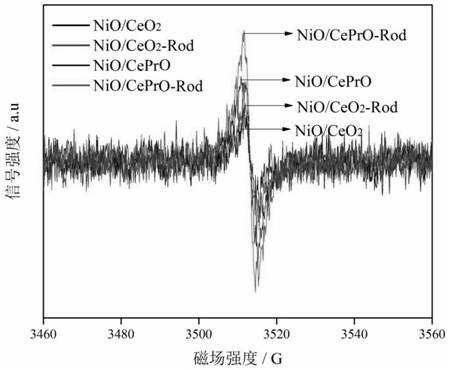

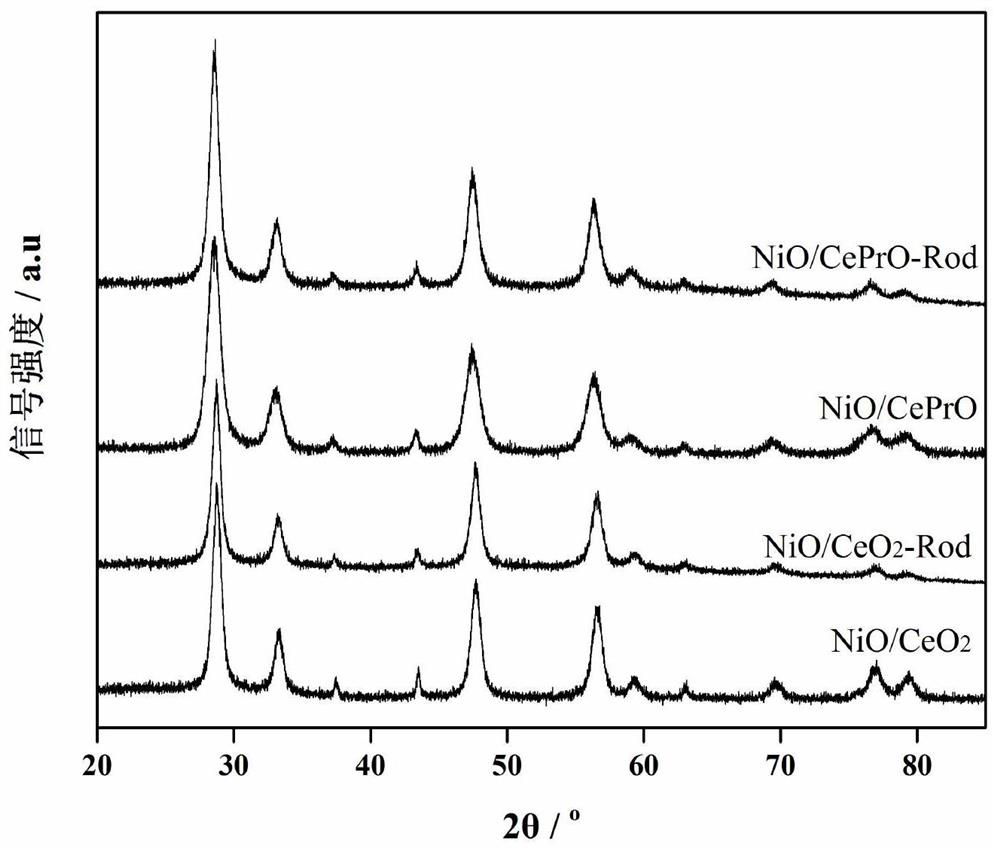

[0041] (1) Preparation of catalyst

[0042] In this specific embodiment, a catalyst in which nickel oxide is supported on a cerium oxide carrier is prepared. The cerium oxide carrier is in the form of nanoparticles and nanorods respectively, and the cerium oxide carrier is doped or not doped with praseodymium. The Ni loading in the final catalyst was 10% based on the total mass of the catalyst. The prepared catalyst is dried, roasted, pressed into tablets and sieved, and packed into a fixed bed. The purity of the chemical reagents described in the present invention are all analytical pure.

Embodiment 1

[0046] Embodiment 1: the preparation of NiO / CePrO catalyst

[0047] The preparation method of the catalyst in Example 1 is similar to that of the comparative example catalyst, except that 1.67 grams of praseodymium nitrate hexahydrate were added simultaneously in the step (1), and the doping of praseodymium in the prepared NiO / CePrO catalyst The impurities are 20%. Wherein, the preparation of the NiO / CePrO catalyst sample of other praseodymium doping amounts is basically the same as this embodiment, only the quality of the praseodymium nitrate hexahydrate added is slightly adjusted, and the present invention adjusts the nitric acid hexahydrate added between 1.67-6.7 grams According to the quality of praseodymium, NiO / CePrO catalysts with different doping amounts were obtained.

Embodiment 2

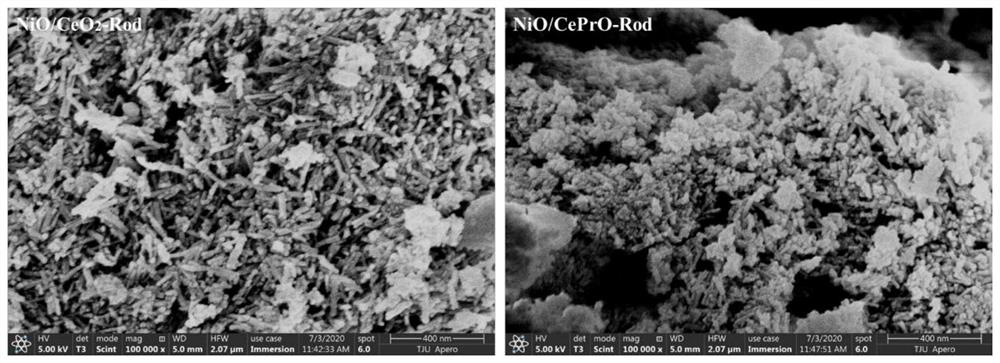

[0048] Example 2: NiO / CeO 2 - Preparation of Rod catalyst

[0049] (1) The cerium nitrate hexahydrate that takes by weighing 1.74g is dissolved in the water of 5ml, the sodium hydroxide that takes by weighing 19.2g is dissolved in the water of 20ml, then both are mixed, then add the water of 15ml again, mix and stir 30min, will The homogeneously stirred solution was transferred to a 100ml hydrothermal crystallization kettle, and kept at 100°C for 24h for crystallization. After the crystallization is completed, filter and wash with deionized water until neutral, collect the solid, dry the solid at 80°C for 12 hours, and then place it in a muffle furnace for 4 hours, and the final solid powder is cerium oxide The nanorods are denoted as CeO 2 -Rod, Rod means that the catalyst has a rod-like structure.

[0050] (2) Weigh 1.483g of nickel nitrate hexahydrate, make a solution of 1.5ml, weigh 2.7g of CeO 2 -Rod carrier, add the configured nickel nitrate hexahydrate solution drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com