Seawater desalination material based on polyurethane foams and preparation method thereof

A technology of polyurethane foam and polyurethane sponge, which is applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problem of low evaporation efficiency, achieve simple operation, reduce cost, and improve heat absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

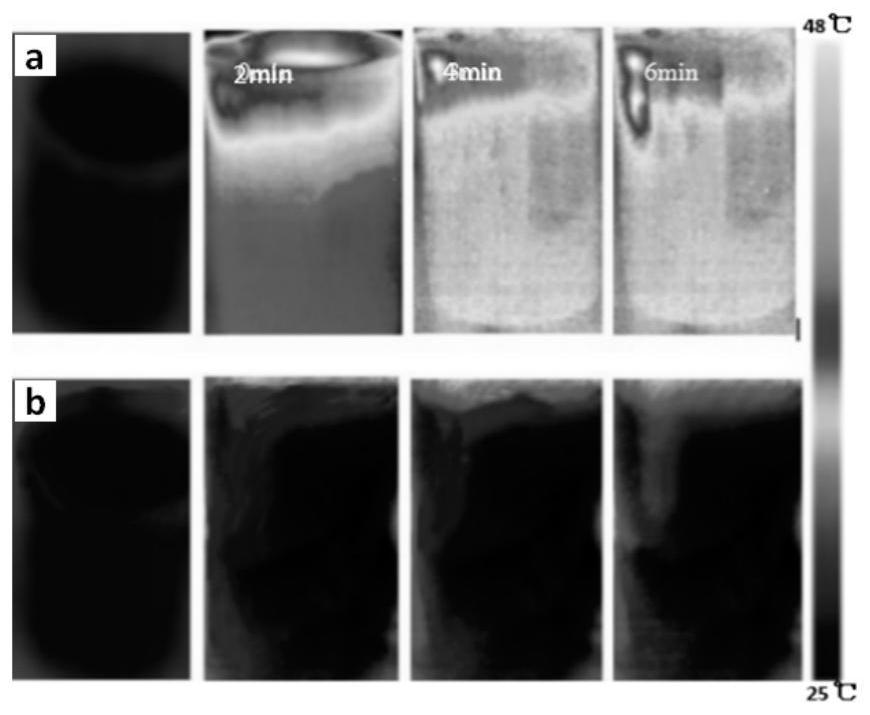

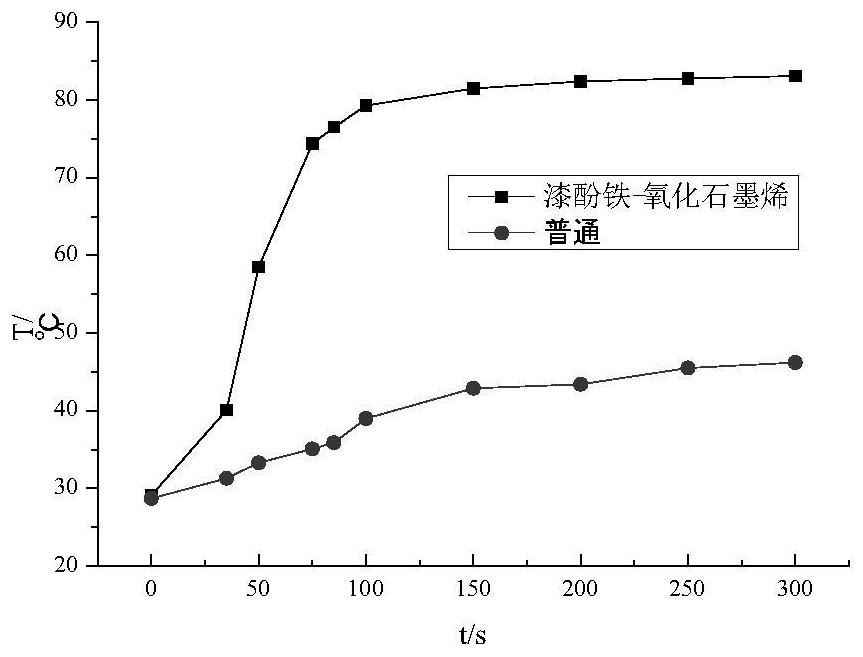

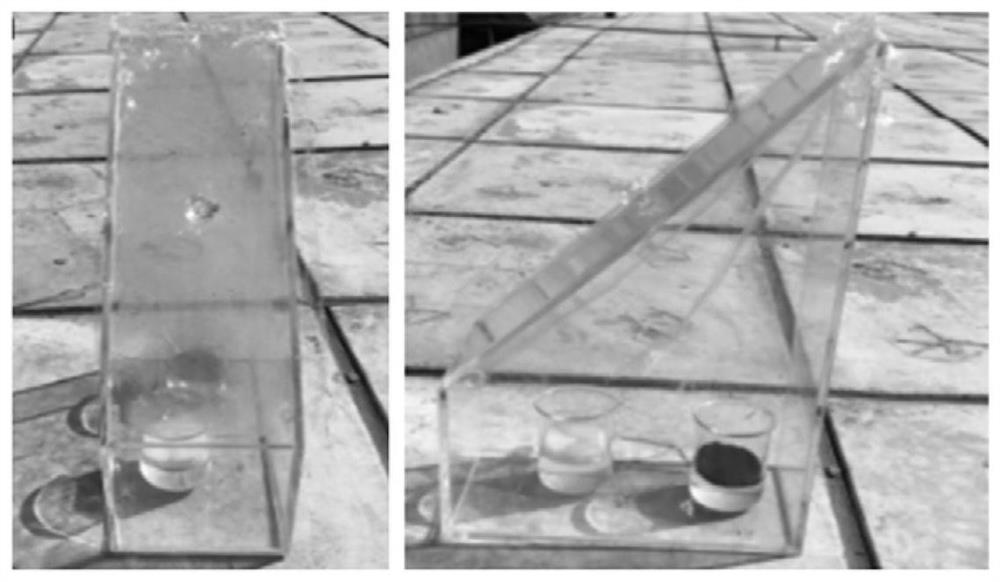

Examples

preparation example Construction

[0028] A preparation method of seawater desalination material based on polyurethane foam, comprising the following steps:

[0029] 1) Preparation of polyurethane sponge grafted with reduced graphene oxide;

[0030] 1-1) Add graphene oxide into a three-necked flask, then add deionized water, and ultrasonically disperse to obtain solution A;

[0031] 1-2) Put the polyurethane sponge in absolute ethanol for ultrasonic treatment, then place it in deionized water for ultrasonic treatment after drying, and then dry; add the pretreated polyurethane sponge to solution A, and heat Stir in a constant temperature water bath for 30-40min to coagulate;

[0032] 1-3) Raise the temperature of the constant temperature water bath to 95-105°C, and add 20 μl of hydrazine hydrate per mg of graphene oxide for in-situ reduction for 1-1.2 hours;

[0033] 1-4) Take out the polyurethane sponge and dry it at 50-55°C for 24-30 hours to obtain a polyurethane sponge grafted with reduced graphene oxide; ...

Embodiment 1

[0041] A preparation method of seawater desalination material based on polyurethane foam, comprising the following steps:

[0042] Step 1. Add 0.1 g of graphene oxide into a 250 mL three-necked flask, add 80 ml of deionized water, and ultrasonically disperse the mixed solution for 10 minutes to obtain solution A;

[0043] Put the polyurethane sponge in absolute ethanol for ultrasonic treatment, after drying, put it in deionized water for ultrasonic treatment, and then dry;

[0044] Add three dried sponges (about 0.5 g) to solution A, and stir in a constant temperature water bath at 30°C for 30 min to coagulate;

[0045] Raise the temperature of the constant temperature water bath to 100°C, and add 20 μl hydrazine hydrate per mg of graphene oxide for in-situ reduction for 1 hour;

[0046] Take out the polyurethane sponge, put it in a low-temperature drying oven at 50°C for 24 hours to dry, and obtain a polyurethane sponge grafted with reduced graphene oxide;

[0047] Step 2. ...

Embodiment 2

[0052] A preparation method of seawater desalination material based on polyurethane foam, comprising the following steps:

[0053] Step 1. Add 0.1 g of graphene oxide into a 250 mL three-necked flask, add 80 ml of deionized water, and ultrasonically disperse the mixed solution for 10 minutes to obtain solution A;

[0054] Put the polyurethane sponge in absolute ethanol for ultrasonic treatment, after drying, put it in deionized water for ultrasonic treatment, and then dry;

[0055] Add three dried sponges (about 0.5 g) to solution A, and stir in a constant temperature water bath at 30°C for 30 min to coagulate;

[0056] Raise the temperature of the constant temperature water bath to 100°C, and add 20 μl hydrazine hydrate per mg of graphene oxide for in-situ reduction for 1 hour;

[0057] Take out the sponge, put it into a low-temperature drying oven at 50°C for 24 hours to dry, and obtain a polyurethane sponge grafted with reduced graphene oxide;

[0058] Step 2. Dissolve 0.25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com