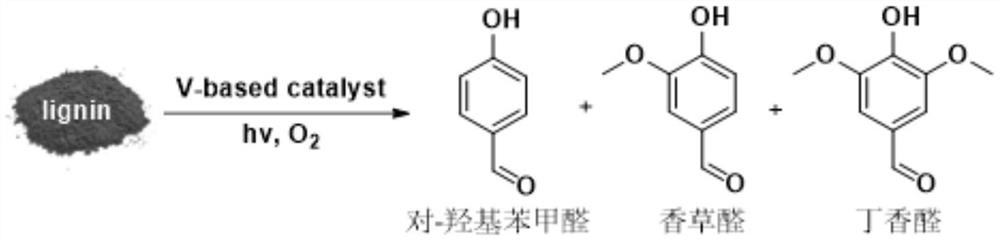

Method for preparing aromatic aldehyde through visible light catalytic oxidation of lignin

A technology of catalytic oxidation and lignin, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve unstudied problems such as the catalytic conversion process and mechanism of vanadium photocatalysts, and achieve wide application value and conditions Gentle, responsive and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

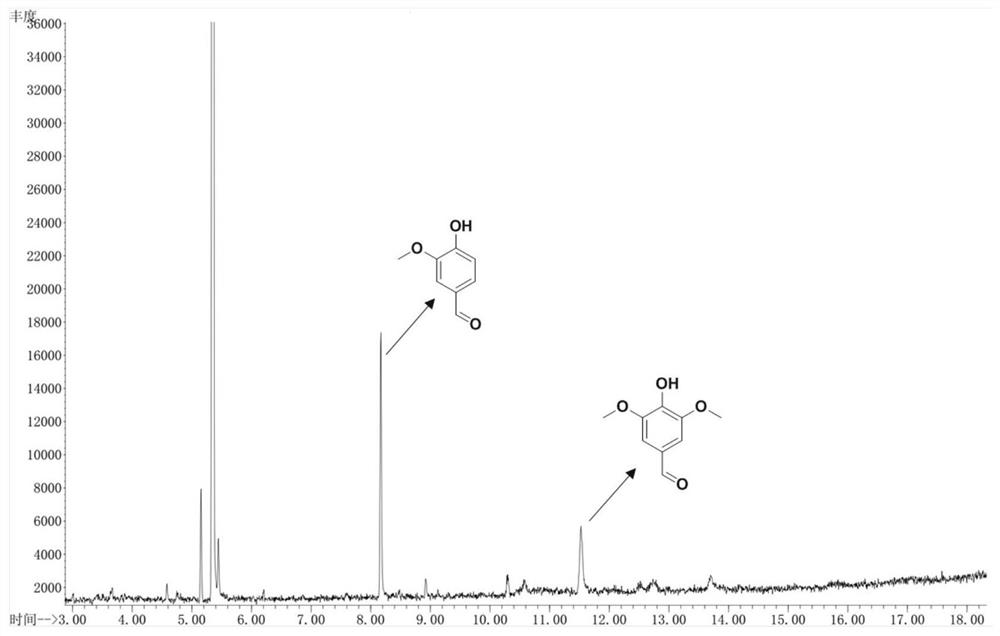

[0025] Add the birch lignin that 20mg dioxane extracts in the quartz photoreaction tube, 2mg acetylacetonate vanadyl catalyst, magneton, and add 1mL solvent acetonitrile (substrate concentration is 20g / L, catalyst and substrate feed mass ratio are 10%). Oxygen replaces the upper air in the reaction tube, and the oxygen pressure is 1 bar. After sealing, put it under the light of 455nm LED light, the stirring speed is 540r / min, the temperature is stable at 30-35 degrees, and react for 24 hours. After the reaction, the liquid product was detected by gas chromatography-mass spectrometry after taking the liquid filter membrane. The products were mainly vanillin and syringaldehyde. The mass yields are shown in Table 1.

Embodiment 2

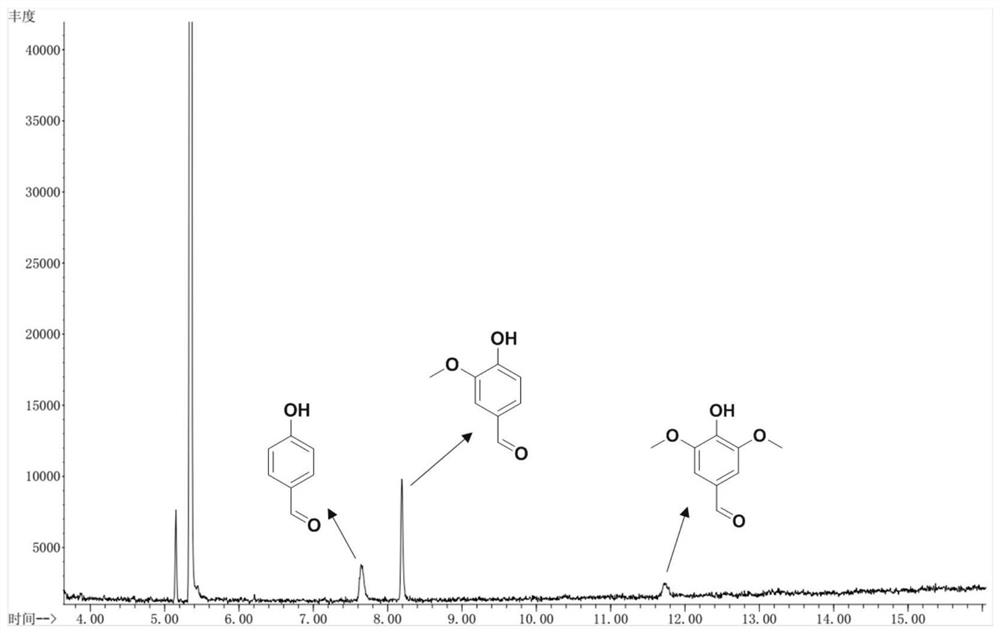

[0027]Add 20mg of extracted birch lignin, 2mg of vanadyl acetylacetonate catalyst, magnetons, and add 1mL of acetone and methanol (volume ratio 9:1) mixed solvent (substrate concentration is 20g / L, catalyst and substrate mass ratio of 10%). Oxygen replaces the air above the reaction tube, the oxygen pressure is 1bar, after sealing, place it under the light of 455nm LED light, the stirring speed is 540r / min, the temperature is stable at 30-35 degrees, and the reaction is 24h. After the reaction, the liquid products were detected by gas chromatography-mass spectrometry. The products were mainly vanillin and syringaldehyde. The mass yields are shown in Table 1.

Embodiment 3

[0029] Add 20 mg of birch lignin extracted in a quartz light reaction tube, 2 mg of vanadyl acetylacetonate catalyst, magneton, and add 1 mL of solvent acetone (substrate concentration is 20 g / L, catalyst and substrate mass ratio is 10%). Oxygen replaces the air above the reaction tube, the oxygen pressure is 1bar, after sealing, place it under the light of 455nm LED light, the stirring speed is 540r / min, the temperature is stable at 30-35 degrees, and the reaction is 24h. After the reaction, the liquid products were detected by gas chromatography-mass spectrometry. The products were mainly vanillin and syringaldehyde. The mass yields are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com