Electrochemical recycling method for indium gallium zinc oxide target material

An indium gallium zinc oxide and electrochemical technology, applied in the field of electrochemical metallurgy, can solve the problems of environmental hazards and cumbersome recycling process, and achieve the effect of avoiding separation steps, simple process flow and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

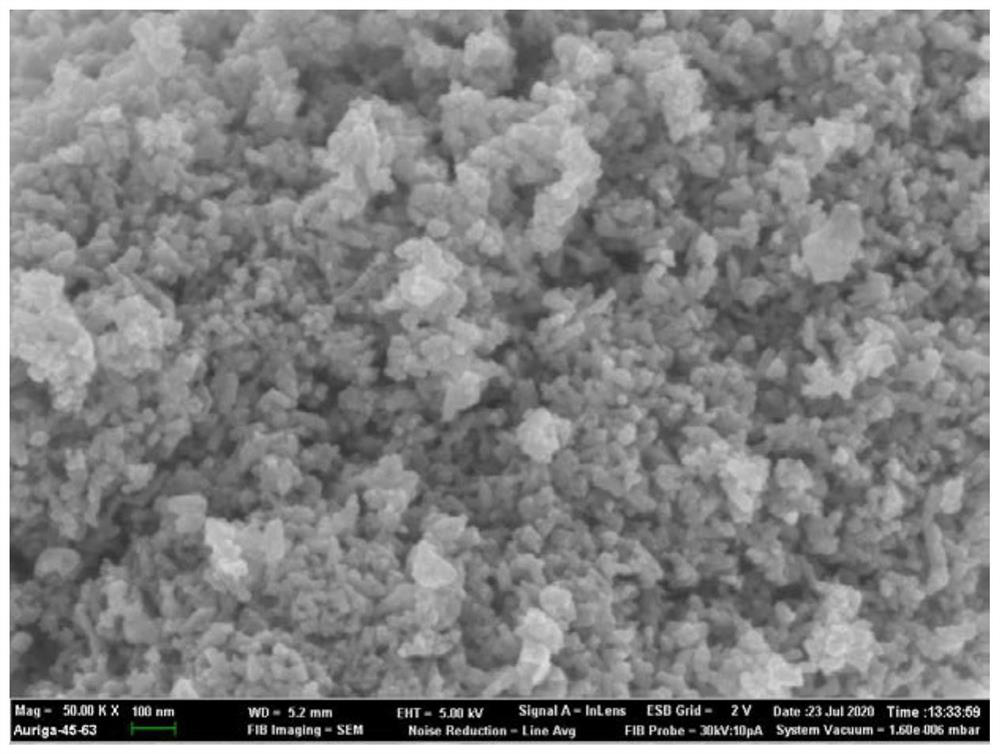

[0056] figure 1 It is a scanning electron microscope image of the indium gallium zinc oxide composite powder disclosed in Example 1. Electrochemical methods for recycling InGaZn targets include:

[0057] CaCl 2 Put the corundum crucible, put the crucible into a vacuum heating box, set the vacuum degree to 100Pa, and keep it at 300°C for 24h;

[0058] Electrolyte CaCl after drying 2 Put it into a high-temperature electrolytic furnace, use the discarded indium gallium zinc oxide as the cathode, and the graphite rod as the anode, and connect the electrolysis power supply;

[0059] Adjust the argon flow rate to 20ml / min, and the heating temperature to 850°C;

[0060] Heat the electrolyte to a molten state, set the voltage to 2.7V for constant potential electrolysis, and obtain an indium-gallium-zinc alloy;

[0061] Prepare NH with a concentration of 1mol / L 4 Cl aqueous solution;

[0062] With the obtained indium gallium zinc alloy as the anode and graphite as the cathode, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com