Heavy metal ion adsorption material and preparation method and application thereof

A technology for heavy metal ions and adsorption materials, which is applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc. Gentle, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment includes the following steps

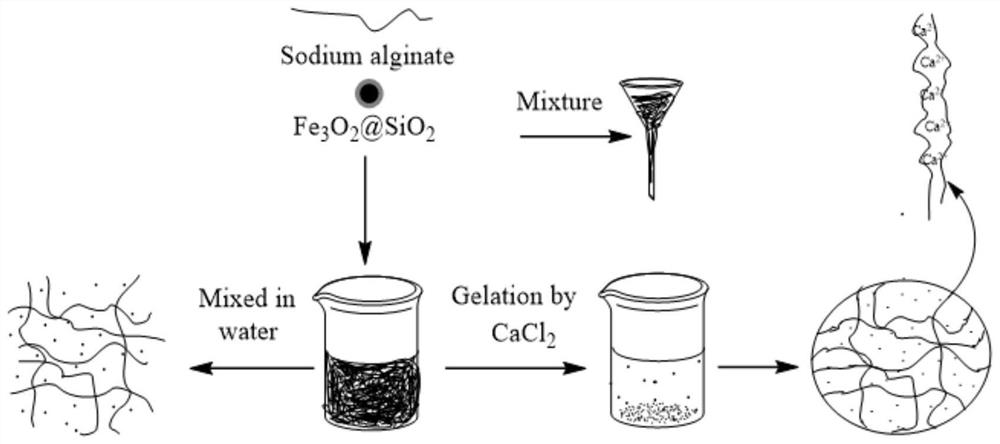

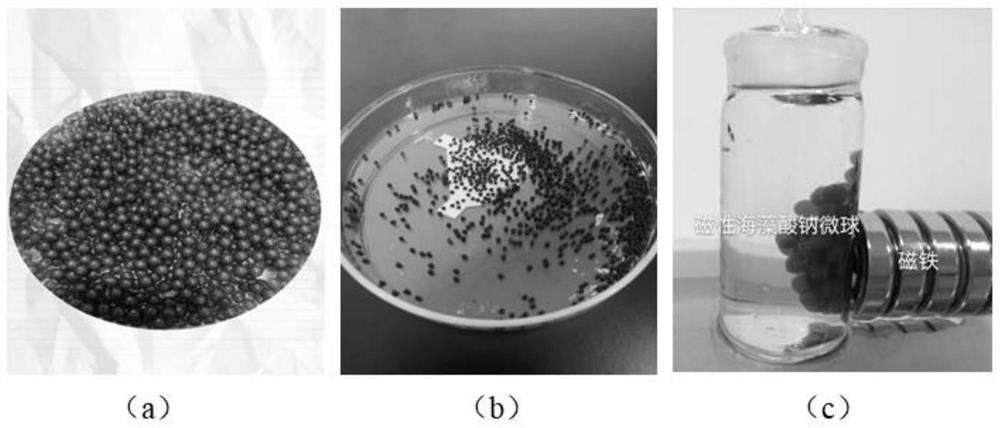

[0036] (1) Preparation of magnetic sodium alginate composite material

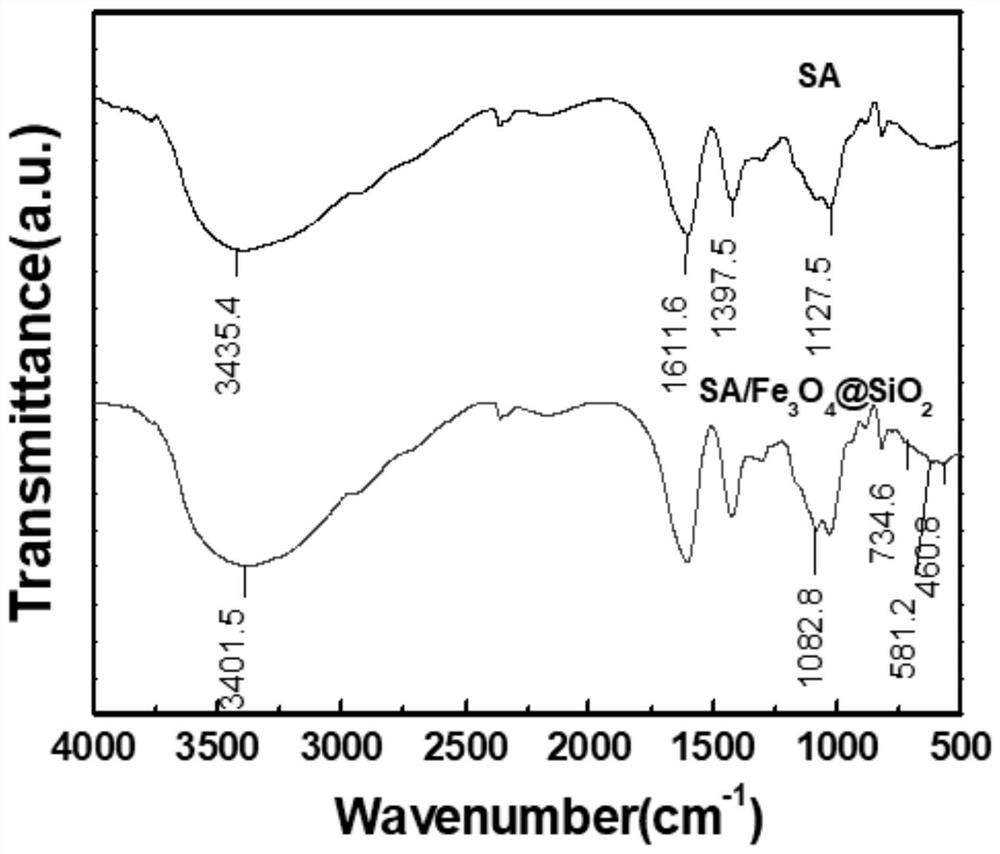

[0037] Using physical blending method to prepare magnetic sodium alginate composite material (SA / Fe 3 O 4 @SiO 2 ), preparation materials: sodium alginate (SA), Fe 3 O 4 @SiO 2 , Calcium chloride (CaCl 2 ). First, dissolve SA in deionized water with a mass ratio of 2%, and stir it magnetically, and then according to the mass ratio SA: Fe 3 O 4 @SiO 2 5:1, take Fe 3 O 4 @SiO 2 Pour the solid into the sodium alginate solution and stir to make it evenly dispersed. At the same time, prepare CaCl with a concentration of 0.2mol / L 2 Solution. Finally, use a separatory funnel to fill the magnetic sodium alginate suspension, and drop it into the prepared CaCl 2 In the solution, let stand for 10h to make Ca 2+ Further infiltrate into the pellets, gelation reaction occurs, and magnetic sodium alginate (SA / Fe 3 O 4 @SiO 2 ) The gel beads, and then the prepared gel bead...

Embodiment 2

[0049] This embodiment includes the following steps

[0050] (1) The mechanism of magnetic sodium alginate composite material to adsorb heavy metal ions

[0051] The main mechanisms for the adsorption of heavy metal ions on magnetic sodium alginate composites include functional groups such as -OH and -COOH and Pb 2+ , Co 2+ , Cu 2+ And other metal ions form complexes to make Ca 2+ With Pb 2+ , Co 2+ When metal ions undergo ion exchange, see the specific process Figure 8 .

[0052] (2) The effect of pH on the adsorption of metal ions by the magnetic sodium alginate composite

[0053] Lead ion solutions of different pH have a very important effect on the adsorption of lead ions by the hydrogel. Due to the different pH value of the lead ion solution, the adsorption performance of the hydrogel to lead ions will be different. In this test, under the same other conditions (adsorption time 120min, lead ion concentration 500mg / L, temperature 15℃), the pH of the metal ion solution is used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com