Method for improving near-infrared emission intensity of up-conversion material

A technology for converting materials and emission intensity, applied in luminescent materials, chemical instruments and methods, nanotechnology, etc., to achieve simple and easy preparation process, improve imaging sensitivity and penetration depth, and reduce autofluorescence and scattering loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

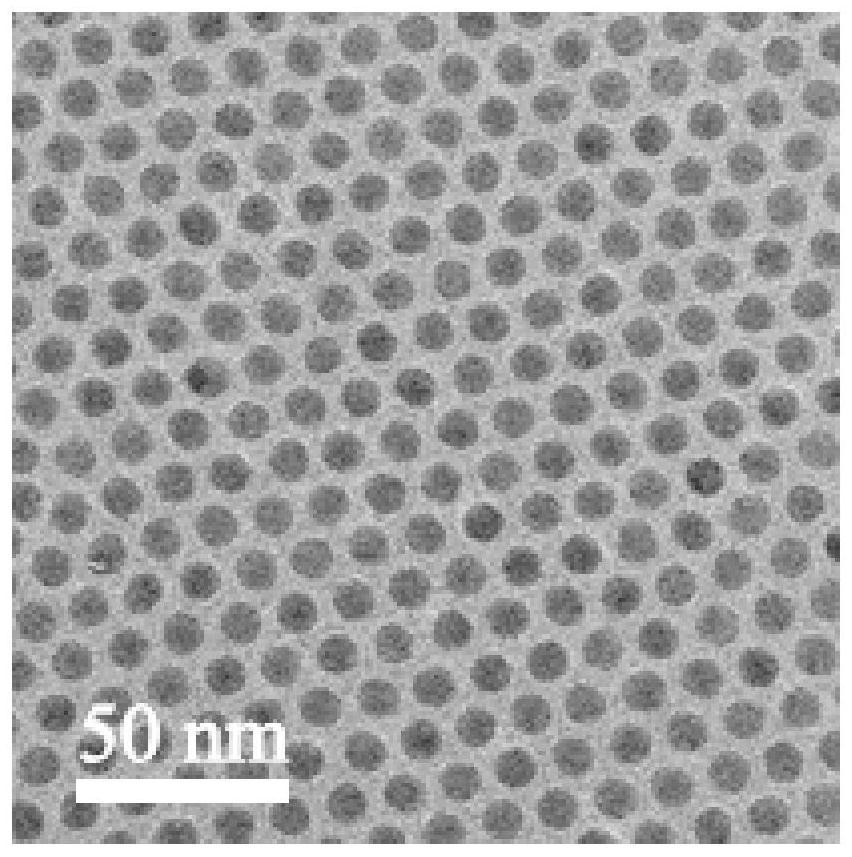

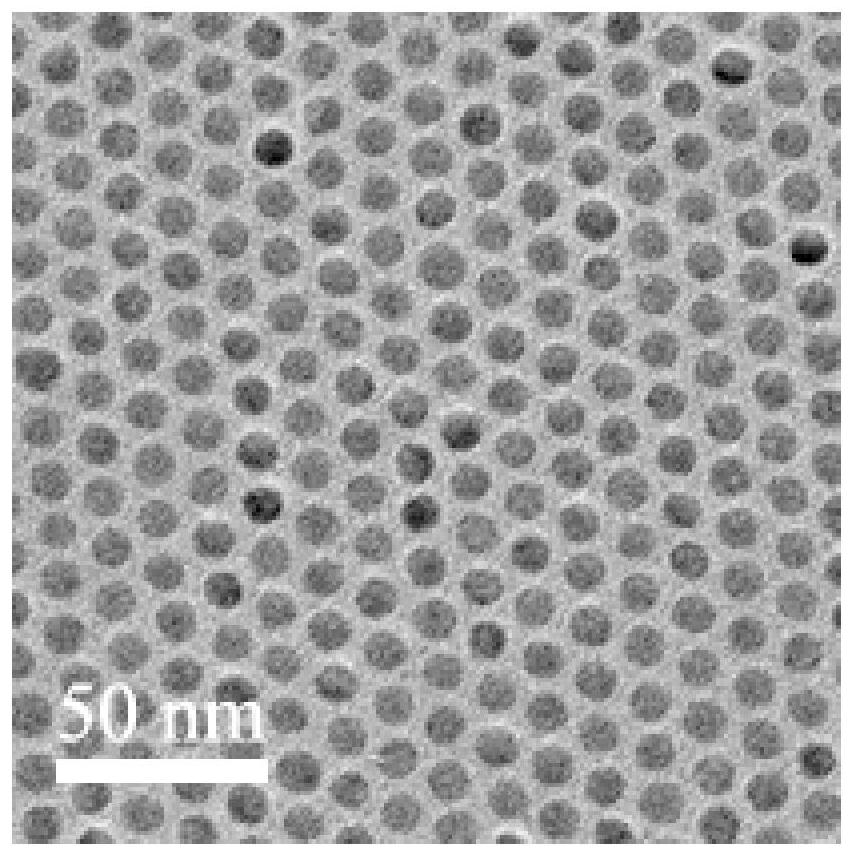

[0028] 1. Add 0.3011g (0.810mmol) GdCl 3 ·6H 2 O, 0.0013g (0.005mmol) Ga(NO 3 ) 3 , 0.0698g (0.18mmol) YbCl 3 ·6H 2 O, 0.0019g (0.005mmol) TmCl 3 ·6H 2 After O was dissolved in 20mL of absolute ethanol, pour it into a flask, add 0.85g (3mmol) stearic acid into it, raise the temperature to 70°C under vigorous magnetic stirring, reflux at constant temperature for 15min, and then slowly add 10mL of 0.3mol / L NaOH The aqueous solution takes about 30 minutes to add dropwise. After the dropwise addition, continue to reflux at 70°C for 100 minutes to obtain a white suspension. Then it was filtered under reduced pressure, and dried in an oven for 12 hours to obtain a rare earth stearate precursor.

[0029]2. Add the rare earth stearate precursor obtained in step 1, 10mL oleic acid and 10mL octadecene into a 100mL three-necked flask, and stir at 160°C for 60min under an anhydrous, oxygen-free, and argon protective atmosphere to form a uniform slightly Light yellow transparent so...

Embodiment 2

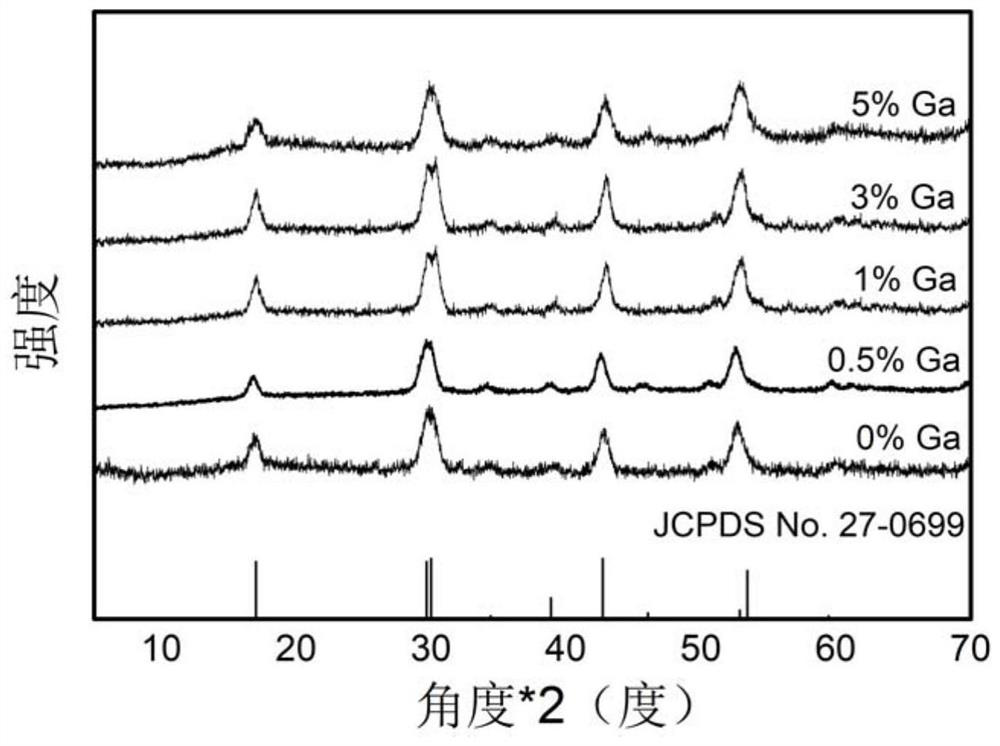

[0031] In this example, GdCl 3 ·6H 2 The amount of O was reduced to 0.805mmol, Ga(NO 3 ) 3 The consumption of increasing to 0.01mmol, other raw material consumption and process conditions are identical with embodiment 1, is prepared into NaGdF 4 : 18% Yb, 0.5% Tm, 1% Ga rare earth up-conversion luminescent material.

Embodiment 3

[0033] In this example, GdCl 3 ·6H 2 The amount of O was reduced to 0.785mmol, Ga(NO 3 ) 3 The consumption of increasing to 0.03mmol, the consumption of other raw materials and process conditions are identical with embodiment 1, is prepared into NaGdF 4 : 18% Yb, 0.5% Tm, 3% Ga rare earth up-conversion luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com