Chemical analysis method for accurately measuring copper content in copper or copper additive

An accurate measurement and additive technology, applied in the field of chemical analysis, can solve the problems of high acid resistance requirements of vessels, great harm to operators, poor detection accuracy, etc., and achieves the effect of strong practicability, high accuracy and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079]A chemical analysis method for accurately measuring the copper content in copper or copper additives, including the following steps:

[0080]1) Prepare drugs: prepare nitric acid (1+1), potassium iodide solution with a concentration of 150g / L, 100g / L hydroxylamine hydrochloride solution, 100g / L potassium thiocyanate solution, sodium pyrophosphate solid (AR.), 10g / L of fresh starch solution.

[0081]2) Preparation and calibration of standard solution:

[0082]a) Preparation of 1mol / L sodium thiosulfate standard solution: Weigh 260g sodium thiosulfate pentahydrate in an Erlenmeyer flask, add an appropriate amount of boiled and carbon dioxide-free water to dissolve it, add 10g anhydrous carbonic acid After dissolving the sodium, filter it with cotton into a 1L volumetric flask, dilute it with carbon dioxide-free water to 1L, and then mix it evenly to obtain a 1mol / L sodium thiosulfate standard solution. Store it for two weeks before use.

[0083]b) Preparation of 0.02mol / L sodium thiosulfat...

Embodiment 2

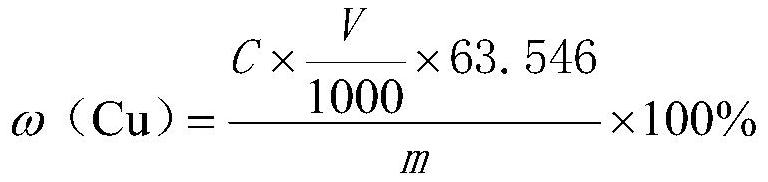

[0103]The difference between Example 2 and Example 1 is that: Example 2 weighed 0.7009 grams of copper sample, and consumed a total of 21.93mL of 0.01997mol / L sodium thiosulfate standard solution. The result is that the mass fraction of copper is:

[0104]

Embodiment 3

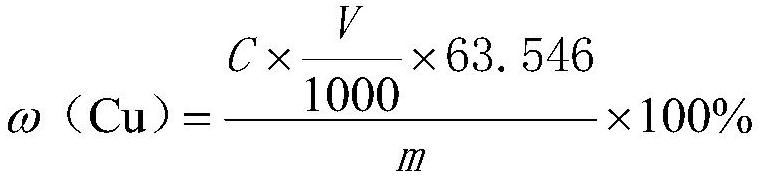

[0106]The difference between Example 3 and Example 1 is that: Example 3 weighed 0.7062 grams of copper sample, and consumed 22.10 mL of 0.01997 mol / L sodium thiosulfate standard solution. The result is that the mass fraction of copper is:

[0107]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com