Adhesive self-repairing hemostatic membrane and preparation method thereof

A self-healing, hemostatic membrane technology, applied in pharmaceutical formulations, pharmaceutical sciences, absorbent pads, etc., can solve the problems of high swelling rate, low mechanical properties, and non-degradable electrospun fiber membranes, and achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

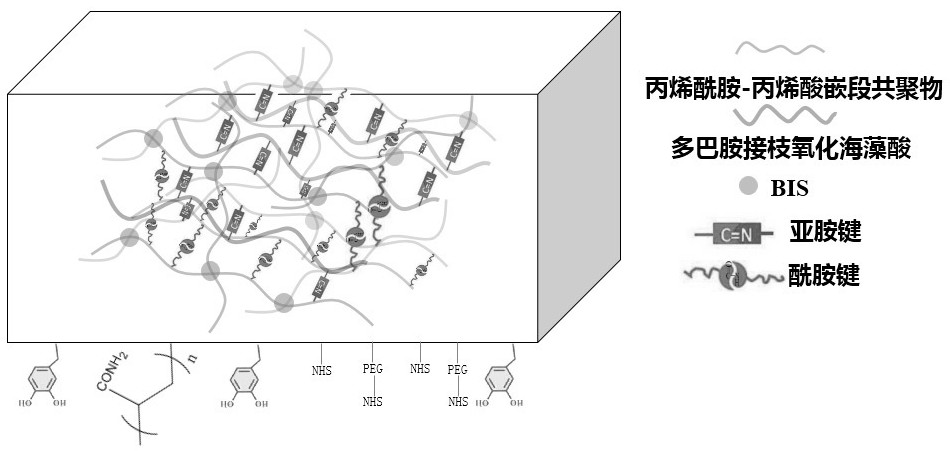

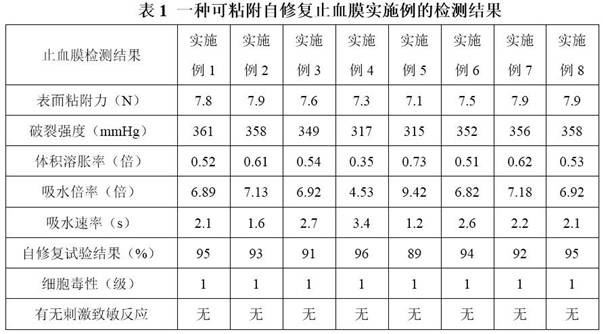

[0051] Example 1 2.5% dopamine grafted oxidized alginic acid (oxidation degree is 85%, dopamine grafting rate is 15%, viscosity is 300mPa·s), 30% acrylamide, 5% N- hydroxysuccinimide acrylate, 0.015%N,N'- methylene bisacrylamide are added into purified water at a temperature of 100-20min Add 1.6% 2- hydroxy -2- methyl -1-[4-(2- hydroxyethoxy) phenyl ]-1- acetone, 20% acrylic acid and 0.6% calcium chloride, stir at 100-200rpm until the solution is uniform, and prepolymerize for 30min under ultraviolet lamp with power of 150W and wavelength of 365nm. Spray the mixture of 150W% acrylic ester PEG-N hydroxysuccinimide ester, 0.6% dopamine, 0.4% acrylamide, 3% acrylic ester N- hydroxysuccinimide ester and 0.018%2- hydroxy -2- methyl -1-[4-(2- hydroxyethoxy) phenyl ]-1- acetone on the surface, and spray it on the surface. The finished gel-like product was put in a mold and placed in a programmed vacuum drying oven. First, it was dried at 4℃ for 1.5h with a vacuum of 100Pa, then at 10℃ wi...

Embodiment 2

[0052]Example 2: 3.5% dopamine grafted oxidized alginic acid (oxidation degree is 80%, dopamine grafting rate is 10%, viscosity is 200mPa·s), 25% acrylamide, 3% N- hydroxysuccinimide acrylate, 0.020%N,N'- methylene bisacrylamide are added into purified water at the temperature of 100-200 Adding 1.6% 2- hydroxy -2- methyl -1-[4-(2- hydroxyethoxy) phenyl ]-1- acetone, 25% acrylic acid and 0.4% calcium chloride, stirring at 100-200rpm until the solution is uniform, prepolymerizing under ultraviolet lamp at power of 150W and wavelength of 365nm for 20 minutes, and Spray the mixture of 1.5% acrylate PEG-N hydroxysuccinimide, 1.25% dopamine, 0.6% acrylamide, 4% acrylate N- hydroxysuccinimide and 0.028%2- hydroxy -2- methyl -1-[4-(2- hydroxyethoxy) phenyl ]-1- acetone on the surface, and The finished gel-like product was put in a mold and placed in a programmed vacuum drying oven. First, it was dried at a vacuum of 100Pa at 4℃ for 2 hours, then at a vacuum of 50Pa at 10℃ for 1 hour, and ...

Embodiment 3

[0053] Example 3 1.5% dopamine grafted oxidized alginic acid (oxidation degree is 90%, dopamine grafting rate is 20%, viscosity is 500mPa·s), 35% acrylamide, 7% N- hydroxysuccinimide acrylate, 0.010%N,N'- methylene bisacrylamide are added into purified water at a temperature of 100-200 Add 1.6% 2- hydroxy -2- methyl -1-[4-(2- hydroxyethoxy) phenyl ]-1- acetone, 15% acrylic acid and 0.5% calcium chloride, stir at 100-200rpm until the solution is uniform, and prepolymerize for 40min under ultraviolet lamp with power of 150W and wavelength of 365nm. Spray the mixture of 0.5% acrylate PEG-N hydroxysuccinimide ester, 0.25% dopamine, 0.2% acrylamide, 2% acrylate N- hydroxysuccinimide ester and 0.009%2- hydroxy -2- methyl -1-[4-(2- hydroxyethoxy) phenyl ]-1- acetone on the surface, and The finished gel-like product was put in a mold and placed in a programmed vacuum drying oven. First, it was dried at a vacuum of 100Pa at 4℃ for 1h, then at a vacuum of 50Pa at 10℃ for 0.5h, and finally a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com