Crude helium refining system and method thereof

A refining system and compression system technology, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve the problem that the low-temperature pure helium is difficult to effectively recover, the multi-stream heat transfer requirements are high, and the pressure energy utilization is unreasonable, etc. problem, to achieve the effect of reducing liquid nitrogen consumption, avoiding low temperature switching operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

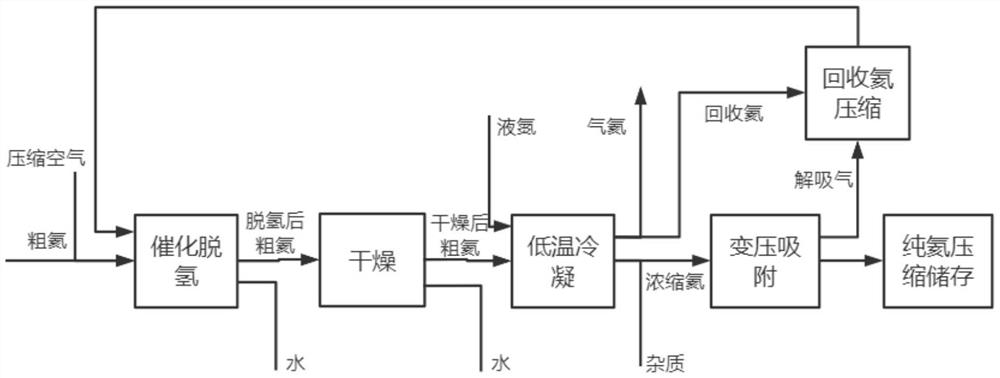

[0033] The present invention is realized through the following technical solutions, as figure 1 As shown, a crude helium refining system includes a catalytic dehydrogenation system, a helium drying system, a medium-pressure low-temperature condensation system, a normal temperature pressure swing adsorption system, a pure helium compression system and a recovery helium compression system; wherein the catalytic dehydrogenation system, helium The drying system, medium pressure low temperature condensation system, normal temperature pressure swing adsorption system, and pure helium compression system are connected in sequence through pipelines; the recovery helium compression system is respectively connected with the medium pressure low temperature condensation system, normal temperature pressure swing adsorption system, and catalytic dehydrogenation system. The pressure of the medium-pressure low-temperature condensation system is 1-3MPa, and the pressure of the normal temperature...

Embodiment 2

[0042] A refining method based on the above crude helium refining system, specifically comprising the following steps:

[0043] Step S1: Input crude helium and compressed gas into a catalytic dehydrogenation system for dehydrogenation treatment to obtain crude helium after dehydrogenation; wherein after dehydrogenation, the concentration of hydrogen in the crude helium is 0-5ppm;

[0044] Step S2: Input the dehydrogenated crude helium into a helium drying system for drying treatment to obtain dried crude helium; wherein, after drying, the concentration of water in the crude helium is 1-2 ppm;

[0045] Step S3: Input the dried crude helium and liquid nitrogen into the medium-pressure low-temperature condensation system respectively, and increase the helium content in the crude helium to 80%-90% at the temperature of liquid nitrogen at normal pressure; obtain concentrated helium and Recovery of helium; the pressure of the medium-pressure low-temperature condensation system is 1-...

Embodiment 3

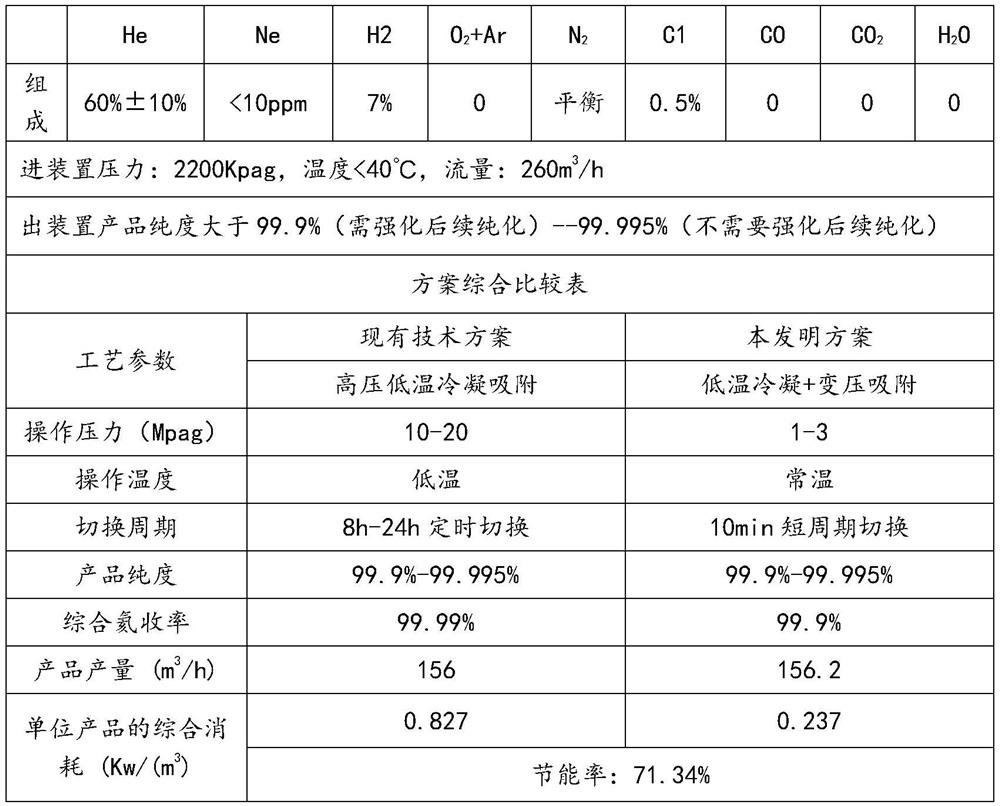

[0049] In this embodiment, the volume of crude helium is 260m 3 / h, taking the inlet device pressure of 2200Kpag as an example, based on the existing engineering experience data, simulated and calculated two different crude helium refining process schemes, and the comparison results are shown in Table 1;

[0050]

[0051] From the above examples, it can be seen that through the process technology combination scheme of "catalytic dehydrogenation + drying + low temperature condensation + normal temperature pressure swing adsorption" of the present invention, the low temperature adsorption process is reduced, the low temperature switching operation is avoided, and the liquid for switching operation is reduced. The influence of nitrogen consumption and adsorption heat on the consumption of liquid nitrogen effectively reduces the consumption of liquid nitrogen to a certain extent. At the same time, due to the reduction of operating pressure, the energy consumption of the device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com