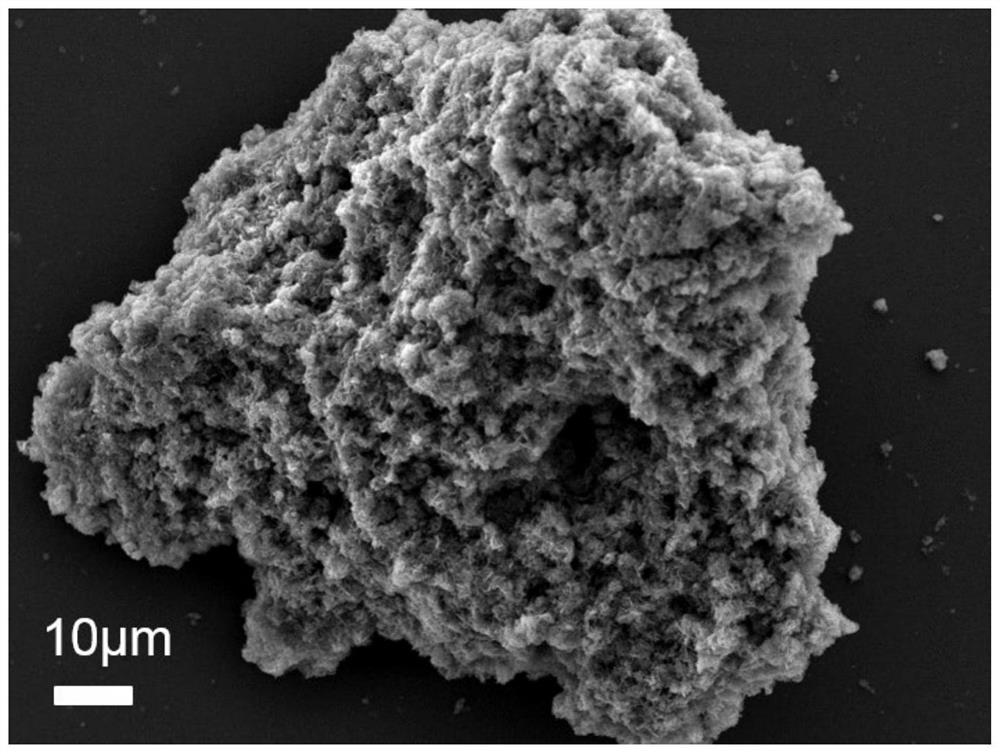

Preparation method of polydopamine derived carbon-coated calcium vanadate nanosheet composite material

A carbon-coated calcium vanadate and polydopamine technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Excellent cycle stability, stable cycle performance, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

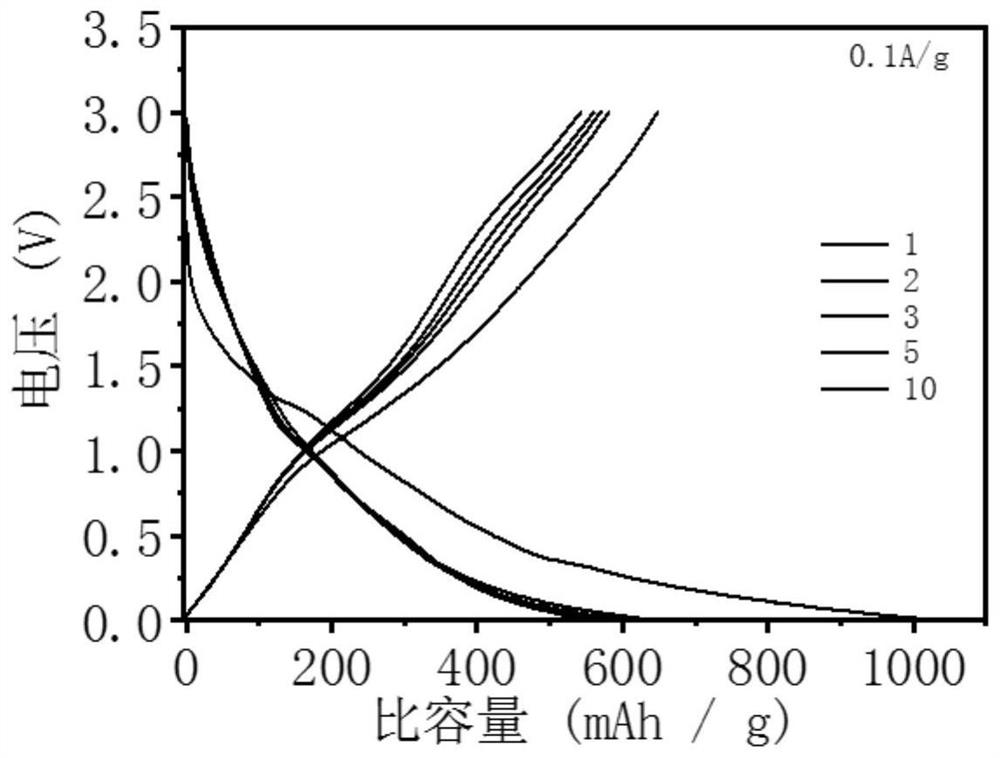

Examples

Embodiment 1

[0028] 1) Take 0.05g CaCl 2 Dissolve 0.786g of vanadyl acetylacetonate in 22ml of absolute ethanol and 3ml of distilled water, and stir for one hour. After the system is uniform, transfer it to a 50ml reaction kettle. After washing with water and suction filtration, the precipitate was collected, and the precipitate was dried in a vacuum oven at 80°C for 3 hours, and the dried solid was pulverized in a mortar and collected for later use.

[0029] 2) Preparation of 50ml Tris solution with pH 8.5: Dissolve 0.7268g Tris in 50ml deionized water, measure the pH with a pH meter, adjust the pH to 8.5 with 6ml / L HCl .

[0030] 3) Take 0.2g CaV 4 o 9 Dissolve in 50ml Tris solution, wait for CaV 4 o 9 After being evenly dispersed in the Tris solution, 0.05 g of dopamine hydrochloride was added, and the solution was stirred for 12 hours after mixing. Then, it was washed with deionized water, centrifuged, and the solid was dried in a vacuum oven at 60° C. for 12 hours, and the black ...

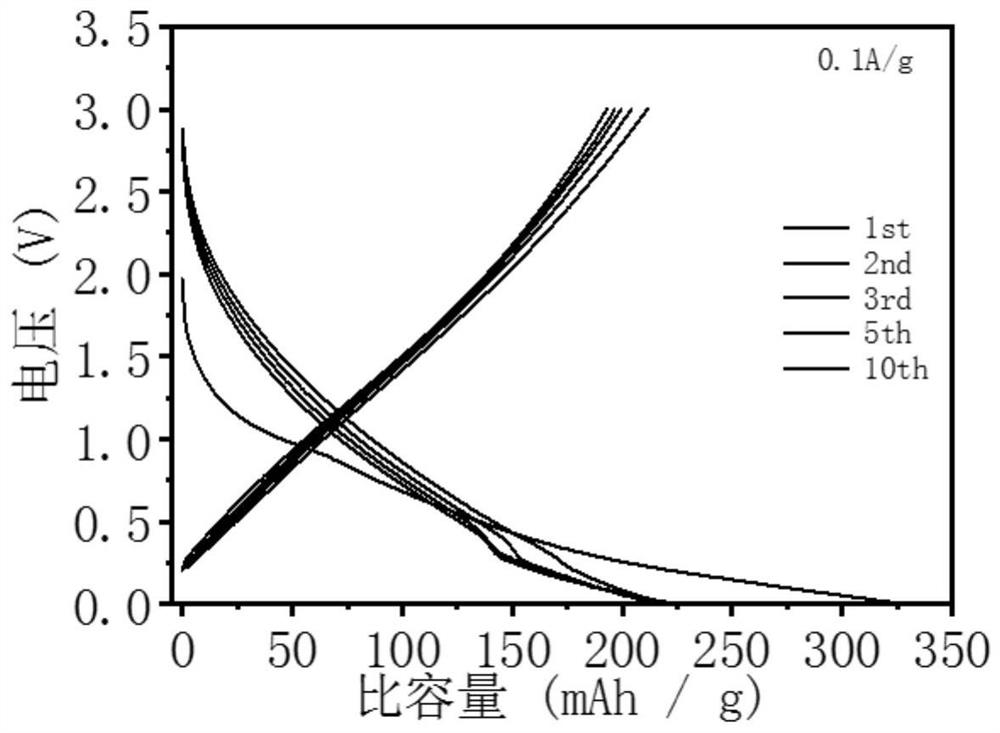

Embodiment 2

[0033] 1) Take 0.05g CaCl 2 Dissolve 0.786g of vanadyl acetylacetonate in 22ml of absolute ethanol and 3ml of distilled water, and stir for one hour. After the system is uniform, transfer it to a 50ml reaction kettle. After washing with water and suction filtration, the precipitate was collected, and the precipitate was dried in a vacuum oven at 80°C for 3 hours, and the dried solid was pulverized in a mortar and collected for later use.

[0034] 2) Preparation of 50ml Tris solution with pH 8.5: Dissolve 0.7268g Tris in 50ml deionized water, measure the pH with a pH meter, adjust the pH to 8.5 with 6ml / L HCl .

[0035] 3) Take 0.2g CaV 4 o 9 Dissolve in 50ml Tris solution, wait for CaV 4 o 9 After being uniformly dispersed in the Tris solution, 0.05 g of dopamine hydrochloride was added, and the solution was stirred for 10 hours after mixing. Then, it was washed with deionized water, centrifuged, and the solid was dried in a vacuum oven at 60° C. for 12 hours, and the black...

Embodiment 3

[0037] 1) Take 0.05g CaCl 2 Dissolve 0.786g of vanadyl acetylacetonate in 22ml of absolute ethanol and 3ml of distilled water, and stir for one hour. After the system is uniform, transfer it to a 50ml reaction kettle. After washing with water and suction filtration, the precipitate was collected, and the precipitate was dried in a vacuum oven at 80° for 3 hours, and the dried solid was ground in a mortar and collected for later use.

[0038] 2) Preparation of 50ml Tris solution with pH 8.5: Dissolve 0.7268g Tris in 50ml deionized water, measure the pH with a pH meter, adjust the pH to 8.5 with 6ml / L HCl .

[0039] 3) Take 0.2g CaV 4 o 9 Dissolve in 50ml Tris solution, wait for CaV 4 o 9 After being uniformly dispersed in the Tris solution, 0.075 g of dopamine hydrochloride was added, and the solution was stirred for 10 hours after mixing. Then, it was washed with deionized water, centrifuged, and the solid was dried in a vacuum oven at 60° C. for 12 hours, and the black s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com