Production process for preparing sodium silicate from sodium sulfate

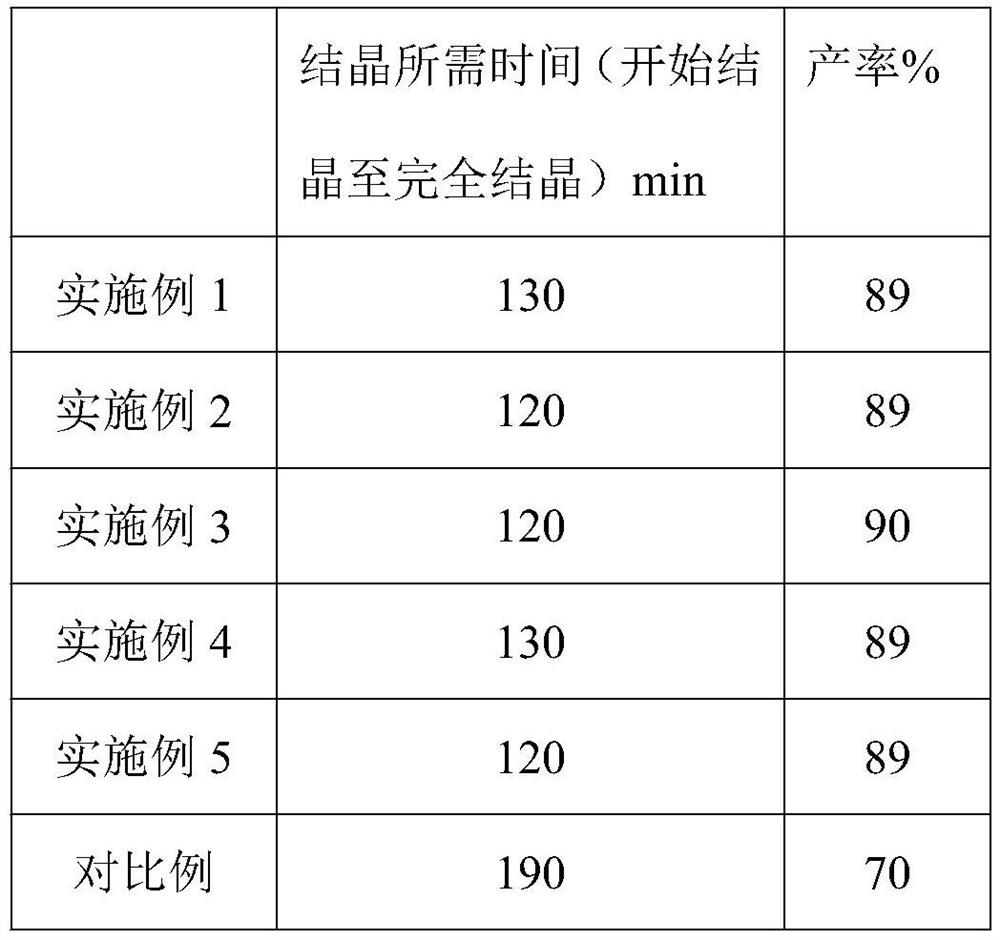

A production process, sodium sulfate technology, applied in the directions of silicate, alkali metal silicate, silicon compound, etc., can solve the problems of slow crystallization speed of sodium silicate, slow down the production efficiency of sodium silicate, etc. The effect of improving crystallization yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Sodium sulfate, limestone, and anthracite are mixed and crushed, passed through a 20-mesh sieve, and calcined in a high-temperature furnace at a calcining temperature of 1000°C, and the mixed powder is calcined to a molten state;

[0019] Step 2: Pour the molten material in step 1 into water to prepare a sodium carbonate solution, add milk of lime to the sodium carbonate solution, react at a temperature of 75°C, filter out the calcium carbonate precipitate, and prepare a sodium hydroxide solution ;

[0020] Step 3: Evaporate and crystallize the sodium hydroxide solution prepared in step 2 to obtain solid sodium hydroxide;

[0021] Step 4: prepare the raw material sodium hydroxide solution, add the solid sodium hydroxide prepared in step 3 into deionized water, wherein 60 g of solid sodium hydroxide is added to every 100 ml of water;

[0022] Step 5: the raw material sodium hydroxide solution prepared in step 4 is mixed with the water glass solution, the volume ...

Embodiment 2

[0025] Step 1: Sodium sulfate, limestone, and anthracite are mixed and crushed, passed through a 25-mesh sieve, and calcined in a high-temperature furnace at a calcination temperature of 1020°C, and the mixed powder is calcined to a molten state;

[0026] Step 2: Pour the molten material in step 1 into water to prepare a sodium carbonate solution, add milk of lime to the sodium carbonate solution, react at a temperature of 77°C, filter out the calcium carbonate precipitate, and prepare a sodium hydroxide solution ;

[0027] Step 3: Evaporate and crystallize the sodium hydroxide solution prepared in step 2 to obtain solid sodium hydroxide;

[0028] Step 4: prepare the raw material sodium hydroxide solution, add the solid sodium hydroxide prepared in step 3 into deionized water, wherein 60 g of solid sodium hydroxide is added to every 100 ml of water;

[0029] Step 5: the raw material sodium hydroxide solution prepared in step 4 is mixed with the water glass solution, the volum...

Embodiment 3

[0032] Step 1: Sodium sulfate, limestone, and anthracite are mixed and crushed, passed through a 30-mesh sieve, and calcined in a high-temperature furnace at a calcining temperature of 1050°C, and the mixed powder is calcined to a molten state;

[0033] Step 2: Pour the molten material in step 1 into water to prepare a sodium carbonate solution, add milk of lime to the sodium carbonate solution, react at a temperature of 80°C, filter out the calcium carbonate precipitate, and prepare a sodium hydroxide solution ;

[0034] Step 3: Evaporate and crystallize the sodium hydroxide solution prepared in step 2 to obtain solid sodium hydroxide;

[0035] Step 4: prepare the raw material sodium hydroxide solution, add the solid sodium hydroxide prepared in step 3 into deionized water, wherein 60 g of solid sodium hydroxide is added to every 100 ml of water;

[0036] Step 5: the raw material sodium hydroxide solution prepared in step 4 is mixed with the water glass solution, the volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com