Spherical germanium-aluminum-lithium phosphate material and composite solid electrolyte prepared from same

A solid electrolyte, germanium aluminum phosphate technology, applied in the field of spherical lithium germanium aluminum phosphate oxide powder materials, composite solid electrolyte, lithium germanium aluminum phosphate material, can solve the problem of electrolyte ion conductivity decline, achieve low viscosity, high Ionic conductivity, high filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

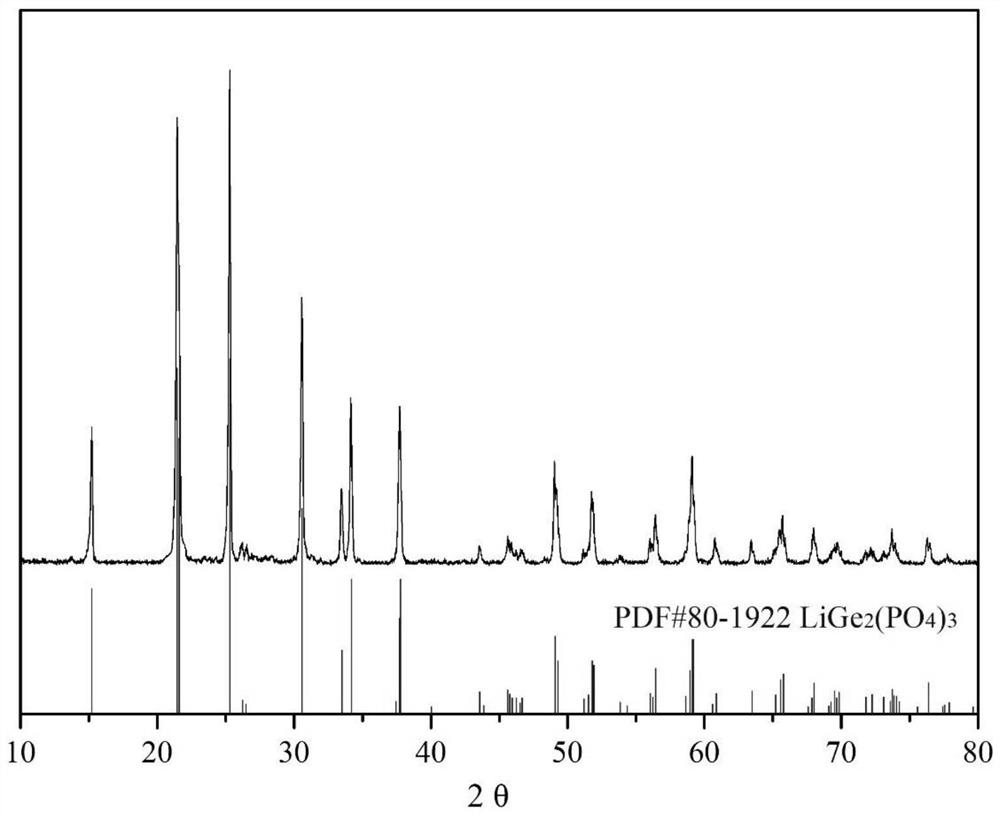

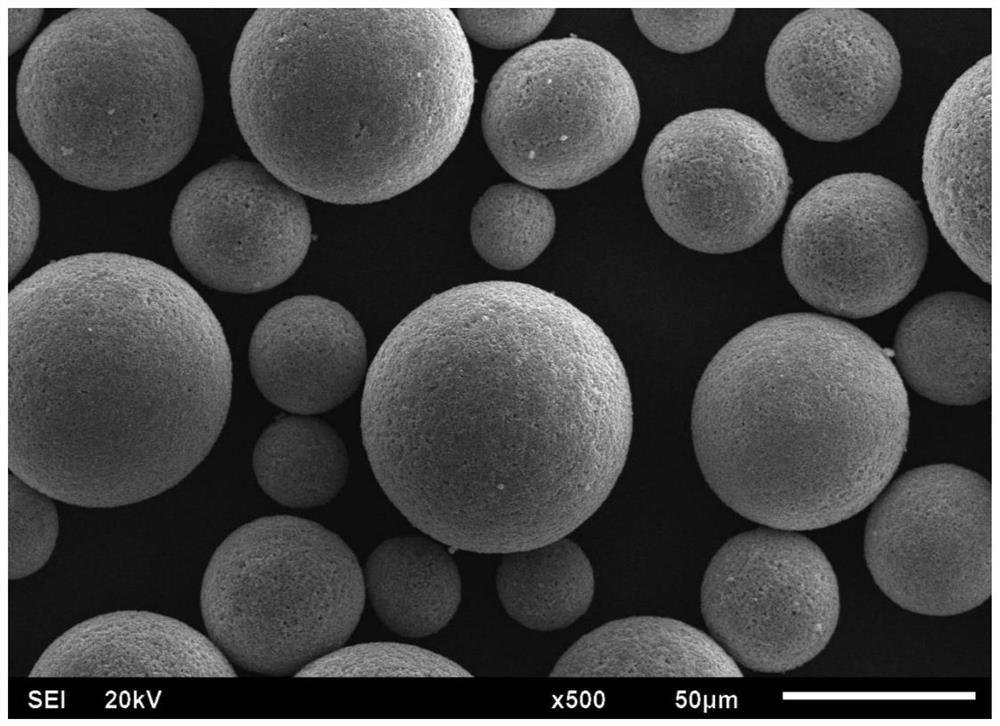

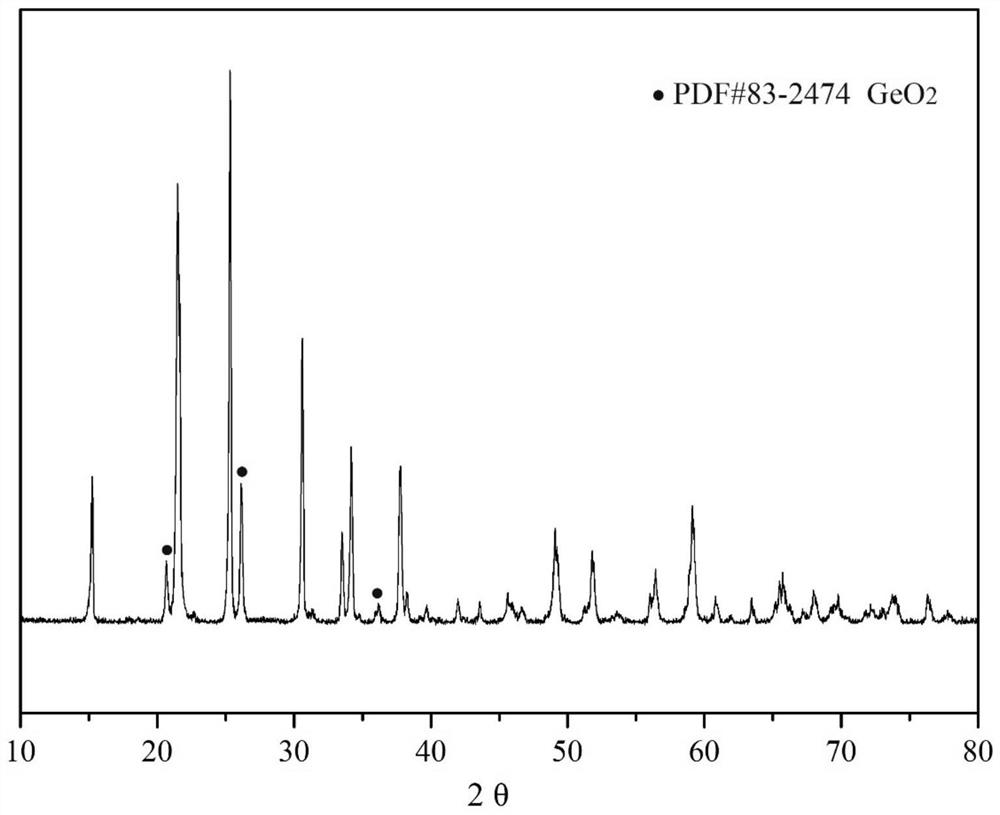

[0074] The spherical lithium germanium aluminum phosphate powder described in this embodiment, raw materials according to Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 stoichiometric ratio.

[0075] The preparation method of the spherical lithium germanium aluminum phosphate powder described in this embodiment comprises the following steps:

[0076] (1) According to the above stoichiometric ratio, weigh 55.4g of lithium carbonate, 25.5g of aluminum oxide, 156.9g of germanium oxide, and 345.1g of ammonium dihydrogen phosphate, and place them in a ball milling tank; then add 874.3g of ball milling media (the type of ball milling media For zirconia balls, wherein, 174.8g of balls with a diameter of 8cm, 262.3g of balls with a diameter of 5cm, and 437.2g of balls with a diameter of 1.5cm are added, and the purity is 94.6%), and the speed of the ball mill is controlled to be 200r / min for ball milling and dispersing for 4 hours; then filter with a 20-mesh nylon sieve to obtain the precursor ...

Embodiment 2

[0090] The materials and preparation method of the spherical lithium germanium aluminum phosphate powder described in this example are the same as those in Example 1.

[0091] The composite solid electrolyte described in this example is prepared from the following raw materials:

[0092] The spherical lithium germanium aluminum phosphate powder 60g;

[0093] Polyethylene oxide 40g;

[0094] Lithium perchlorate 2.7g.

[0095] The preparation method of the composite solid electrolyte described in this example is the same as that in Example 1.

Embodiment 3

[0097] The materials and preparation method of the spherical lithium germanium aluminum phosphate powder described in this example are the same as those in Example 1.

[0098] The composite solid electrolyte described in this example is prepared from the following raw materials:

[0099] The spherical lithium germanium aluminum phosphate powder 70g;

[0100] Polyethylene oxide 30g;

[0101] Lithium perchlorate 2g.

[0102] The preparation method of the composite solid electrolyte described in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com