Alkali-activated regenerated micro-powder foam concrete and preparation method thereof

A technology of foam concrete and recycled micropowder, which is applied in the field of building materials to achieve the effects of low cost, improved environment and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

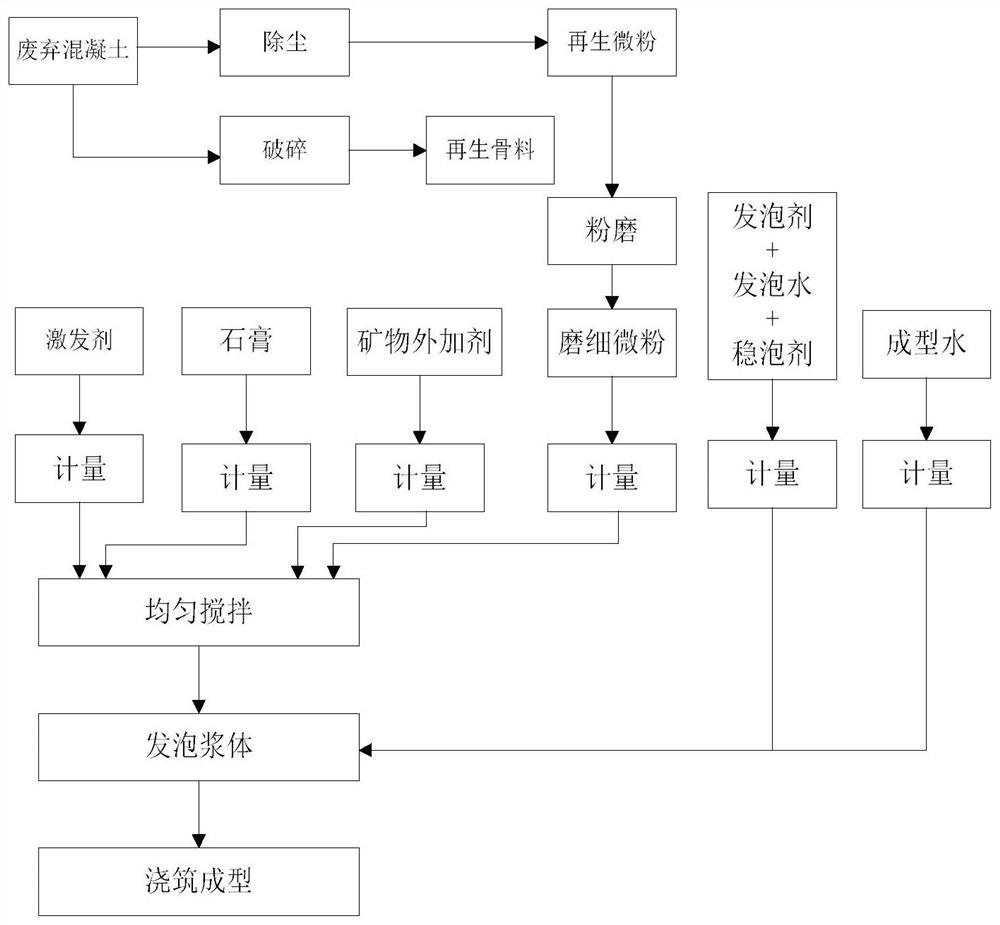

Method used

Image

Examples

Embodiment 1

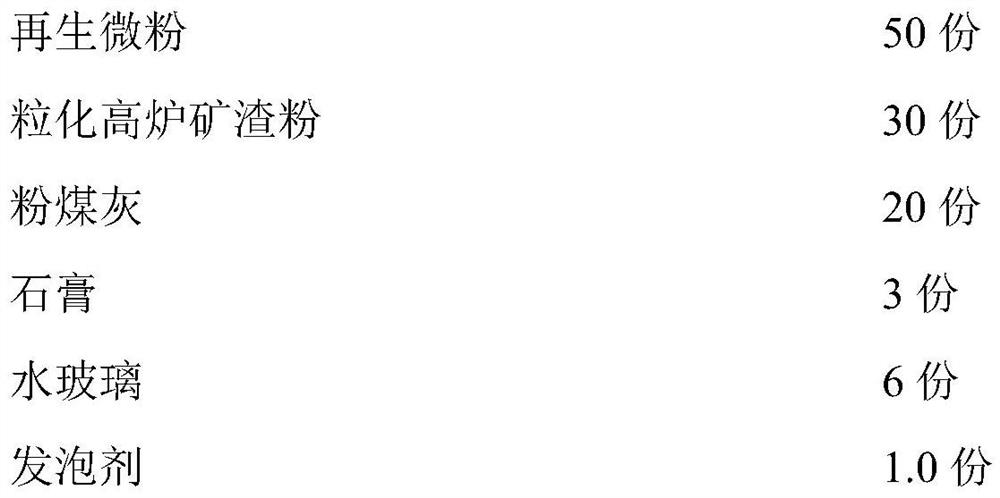

[0035] An alkali-activated regenerated micropowder foam concrete (by mass parts) contains the following components:

[0036]

[0037]

[0038] 50 parts of regenerated micropowder (obtained after the fine powder collected in the winnowing process in the waste concrete crushing process is ground to 1.8% through an 80 μm square hole sieve), 30 parts of granulated blast furnace slag powder, 20 parts of fly ash, and 3 parts of dihydrate Gypsum and 6 parts of sodium silicate (the parts by weight are calculated as sodium oxide) are uniformly mixed to prepare a premix. Then add 1 part of hydrogen peroxide (foaming agent) with a concentration of 30wt% into 30 parts of foaming water for dilution and mixing, add 0.05 part of calcium stearate (foam stabilizer) to obtain a foam, add the foam to the premix, add 20 parts of molding water, stirred slowly for 2-5 minutes, until the foam is evenly dispersed in the slurry to obtain a foamed slurry, injection molded, put into a standard cur...

Embodiment 2

[0040] An alkali-activated regenerated micropowder foam concrete (by mass parts) contains the following components:

[0041]

[0042] 70 parts of regenerated micropowder (obtained after the fine powder collected in the winnowing process in the waste concrete crushing process is ground to 1.8% through an 80 μm square hole sieve), 10 parts of granulated blast furnace slag powder, 20 parts of fly ash, and 2 parts of dihydrate Gypsum and 6 parts of sodium silicate (the parts by weight are calculated as sodium oxide) are uniformly mixed to prepare a premix. Then add 2 parts of hydrogen peroxide (foaming agent) with a concentration of 30wt% to 60 parts of foaming water for dilution and mixing, add 0.1 part of hydroxypropyl methylcellulose ether (foam stabilizer) to obtain a foam, and add the foam to the ready-mixed After feeding, add 20 parts of molding water, stir slowly for 2 minutes to 5 minutes, until the foam is evenly dispersed in the slurry, obtain a foamed slurry, injecti...

Embodiment 3

[0044] An alkali-activated regenerated micropowder foam concrete (by mass parts) contains the following components:

[0045]

[0046] 50 parts of regenerated micropowder (obtained by grinding the fine powder collected in the winnowing process in the waste concrete crushing process to 1.8% through an 80 μm square hole sieve), 30 parts of granulated blast furnace slag powder, 10 parts of fly ash, and 1 part of dihydrate Gypsum and 5 parts of sodium silicate (the parts by weight are calculated as sodium oxide) are uniformly mixed to prepare a premix. Then add 1.5 parts of plant protein foaming agent (foaming agent) to 45 parts of foaming water for dilution and mixing, after foaming by a physical foaming machine, add 0.1 part of hydroxypropyl methylcellulose ether (foam stabilizer) To obtain foam, add foam to the premix, add 20 parts of molding water, stir slowly for 2 minutes to 5 minutes, until the foam is evenly dispersed in the slurry, obtain foam slurry, injection molding,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com