Osteoinductive active extract and preparation method thereof

An extract and osteoinductive technology, which is applied in the fields of pharmaceutical formulation, drug delivery, and medical science, can solve the problems of complexity, increased production costs, and many types of ingredients, and achieve low production costs, short production cycles, and improved osteoinductive production. The effect of bone activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

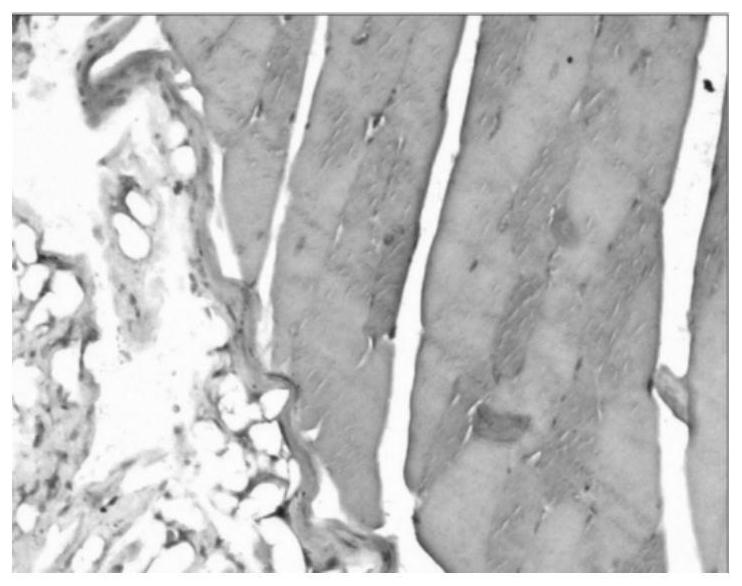

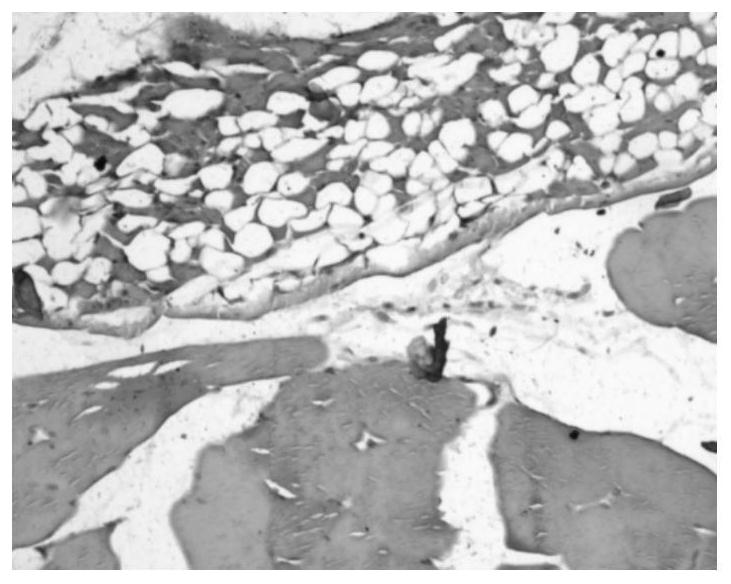

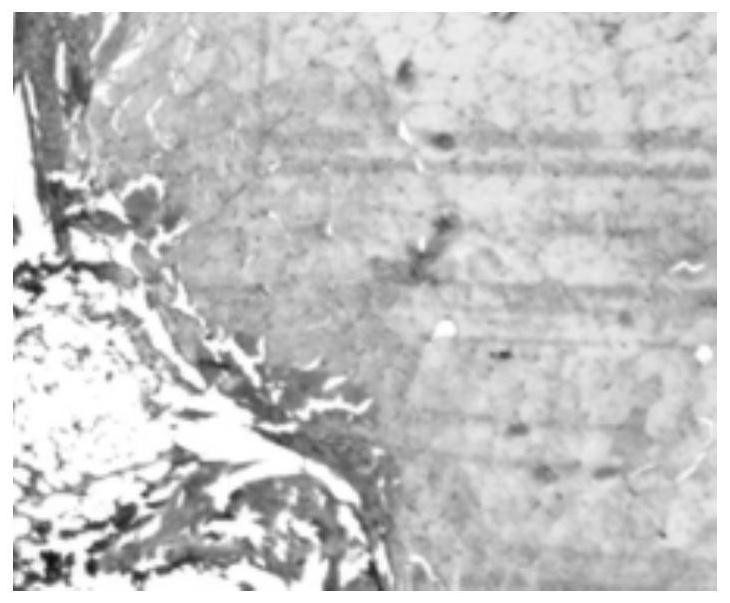

Image

Examples

Embodiment 1

[0071] A preparation method of an osteoinductive active extract, comprising the steps of:

[0072] (1) Pulverization: The cortical bone block is pulverized at low temperature to form cortical bone particles, and the pulverization step uses liquid nitrogen to keep the temperature at -20°C;

[0073] (2) Degreasing: Add cortical bone particles to the reactor, then add methanol equivalent to 0.3 times the weight of cortical bone particles, and 0.7 times chloroform, react at room temperature for 5 hours, replace the degreasing solution, degrease again, and filter to obtain the degreased cortical bone particles;

[0074] (3) Decalcification: soak the degreased cortical bone particles obtained in step (2) completely in a decalcification solution (0.4mol / L hydrochloric acid), put them in an ultrasonic reactor at room temperature for 2 hours, and replace the decalcification solution again Decalcified twice, filtered to obtain cortical bone particles after decalcification;

[0075] (4...

Embodiment 2

[0086] A preparation method of an osteoinductive active extract is basically the same as in Example 1, the difference being:

[0087] (1) Pulverization: The cortical bone blocks are pulverized at low temperature to form cortical bone particles, and the pulverization step uses liquid nitrogen to keep the temperature at -22°C;

[0088] (5) Extraction: the cortical bone particles obtained in step (4) after decontamination are added to the extract, and the extract is obtained by ultrasonic reaction at room temperature, the extract is concentrated, and the concentrated extract is extracted at room temperature under dialysis;

[0089] The preparation method of the extract is as follows: add urea 0.6g, calcium chloride 150g, alpha-lipoic acid 15g, guanidine hydrochloride 60g into water and stir until dissolved, dilute to 1L with water, then add N-ethylmaleimide 1.5 g of amine to obtain the extract.

[0090] The osteoinductive activity extract obtained in Implementation 2 was analyz...

Embodiment 3

[0092] A preparation method of an osteoinductive active extract is basically the same as in Example 1, the difference being:

[0093] (1) Pulverization: The cortical bone blocks are pulverized at low temperature to form cortical bone particles, and the pulverization step uses liquid nitrogen to maintain the temperature at -21°C;

[0094] (2) Degreasing: Add cortical bone grains to the reactor, then add methanol equivalent to 0.3 times the weight of cortical bone grains, and chloroform 0.7 times the weight, react at room temperature for 6 hours, replace the degreasing solution, degrease again, and filter to obtain the degreased cortical bone particles;

[0095] (5) Extraction: the cortical bone particles obtained in step (4) after decontamination are added to the extract, and the extract is obtained by ultrasonic reaction at room temperature, the extract is concentrated, and the concentrated extract is extracted at room temperature under dialysis;

[0096] The preparation met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com