Method for extracting lentinan by two-step enzyme, lentinan extract and application of lentinan extract

A technology of lentinan and extract, which is applied in the field of two-step enzymatic extraction of lentinan and lentinan extract, to achieve the effects of increasing polysaccharide yield, promoting separation, and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

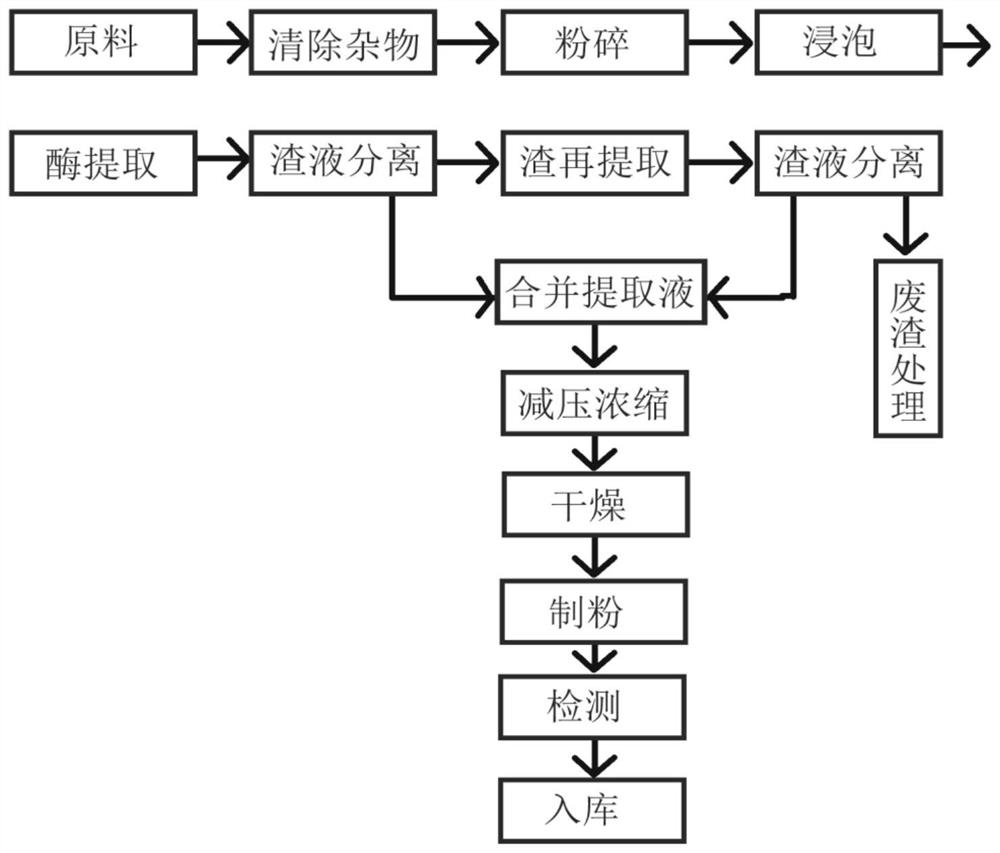

[0046] Embodiment 1 Two-step enzyme extraction method of Lentinan of the present invention (1)

[0047] 1. Extraction of Lentinan

[0048] Follow the steps below to extract lentinan:

[0049] 1) Select clean shiitake mushrooms, carefully remove debris and dry in the sun, totaling 100kg, crushed to 30 mesh;

[0050] 2) Soaking: Process the drinking water of urban residents into pure water, and soak at room temperature for 3 hours with a material-to-liquid ratio of 1:10;

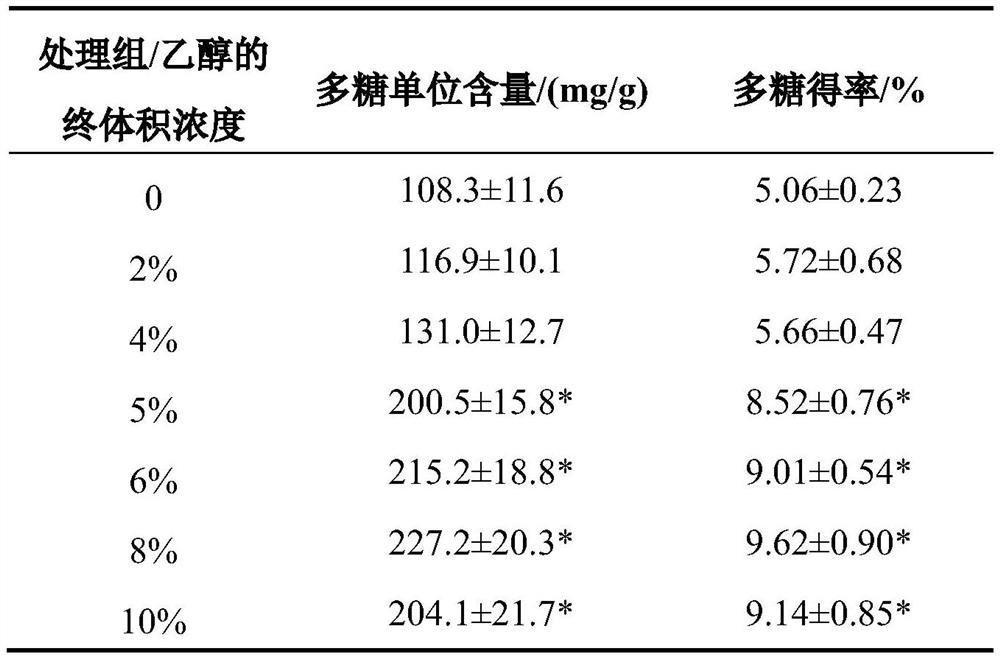

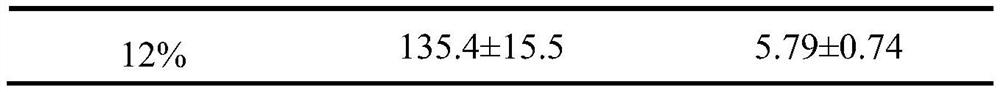

[0051] 3) Enzyme extraction: add cellulase and food-grade ethanol, the amount of cellulase added is 800U / g, and the final volume concentration of food-grade ethanol is set to 0, 2%, 4%, 5%, 6%, 8% %, 10%, 12% eight gradients, temperature 40°C, react in an enzyme reactor for 10 hours, the reaction process requires intermittent stirring, 100 revolutions per minute, and the stop ratio is 1:1;

[0052] 4) Slag-liquid separation: the extract in the enzyme reactor enters the horizontal unloading centrifuge, and t...

Embodiment 2

[0072] Embodiment 2 The method (two) of two-step enzyme extracting lentinan of the present invention

[0073] 1. Extraction of Lentinan

[0074] Follow the steps below to extract lentinan:

[0075] 1) Choose clean shiitake mushrooms, carefully remove sundries, dry in the sun, total 100kg, crush to 40 mesh;

[0076] 2) Soaking: Process the drinking water of urban residents into pure water, and soak at room temperature for 2 hours with a material-to-liquid ratio of 1:10;

[0077] 3) Enzyme extraction: add cellulase and food-grade ethanol, the amount of cellulase added is 900U / g, the final volume concentration of food-grade ethanol is 5%, the temperature is 45 ° C, react in an enzyme reactor for 8 hours, and react The process requires intermittent stirring, 100 revolutions per minute, and the stop ratio is 1:1;

[0078] 4) Slag-liquid separation: the extract in the enzyme reactor enters the horizontal unloading centrifuge, and the separated extract enters the conical storage t...

Embodiment 3

[0089] Embodiment 3 The method (three) of two-step enzyme extracting lentinan of the present invention

[0090] 1. Extraction of Lentinan

[0091] Follow the steps below to extract lentinan:

[0092] 1) Select clean shiitake mushrooms, carefully remove debris and dry in the sun, a total of 100kg, crushed to 20 mesh;

[0093] 2) Soaking: Process the drinking water of urban residents into pure water, and soak at room temperature for 4 hours with a material-to-liquid ratio of 1:10;

[0094] 3) Enzyme extraction: add cellulase and food-grade ethanol, the addition of cellulase is 600U / g, the final volume concentration of food-grade ethanol is 10%, the temperature is 35 ° C, react in an enzyme reactor for 12 hours, and the reaction The process requires intermittent stirring, 100 revolutions per minute, and the stop ratio is 1:1;

[0095] 4) Slag-liquid separation: the extract in the enzyme reactor enters the horizontal unloading centrifuge, and the separated extract enters the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com