Oral ulcer film with repairing effect and preparation method of oral ulcer film

A technology for oral ulcers and repairing effect, applied in the field of oral care, can solve problems such as complex production process, and achieve the effects of simple and safe ingredients, obvious repairing effect, and simple and convenient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

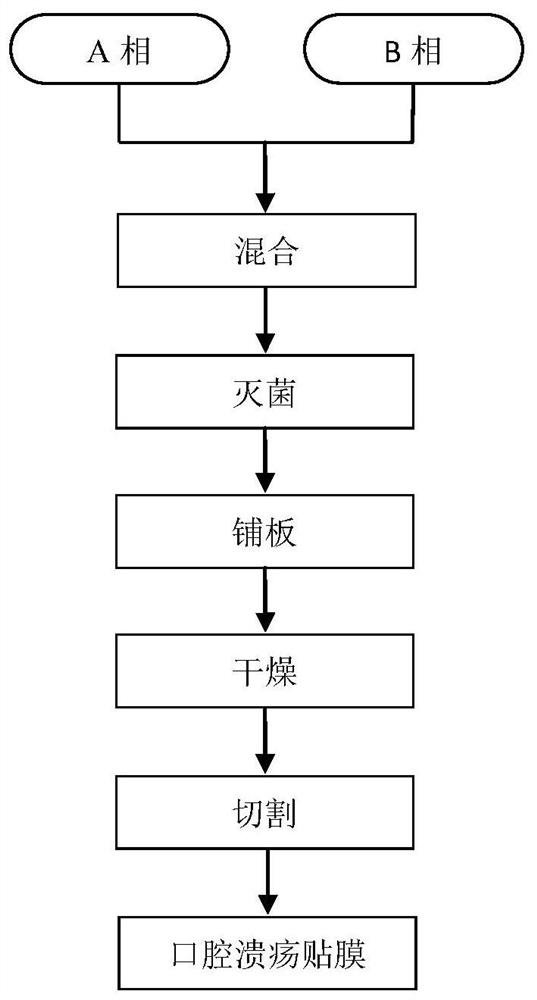

[0040] The present invention also provides a preparation method of oral ulcer patch with repairing effect, such as figure 1 As shown, the simple summary can include the preparation of phase A and phase B, after mixing phase A and phase B, sterilization, laying, drying, and cutting to obtain oral ulcer veil. Specifically, the method includes the following steps:

[0041] Dissolving hyaluronic acid, ectoine, ergothioneine and pentylene glycol in water to obtain phase A;

[0042] Dissolving chitosan, polyvinyl alcohol and glycerin in water to obtain phase B;

[0043] Mix phase A and phase B to obtain a colloid;

[0044] The colloid is sterilized, plated, dried and cut to obtain a repairing oral ulcer patch.

[0045] In a specific embodiment, in the phase A, the mass ratio of the hyaluronic acid, the ectoine and the ergothioneine is 1:(0.1-3):(0.1-2), Preferably it is 1:(0.5-1.5):(1-2). The mass ratio of pentanediol to the hyaluronic acid is (0.5-4):(5-15).

[0046] In a speci...

Embodiment 1

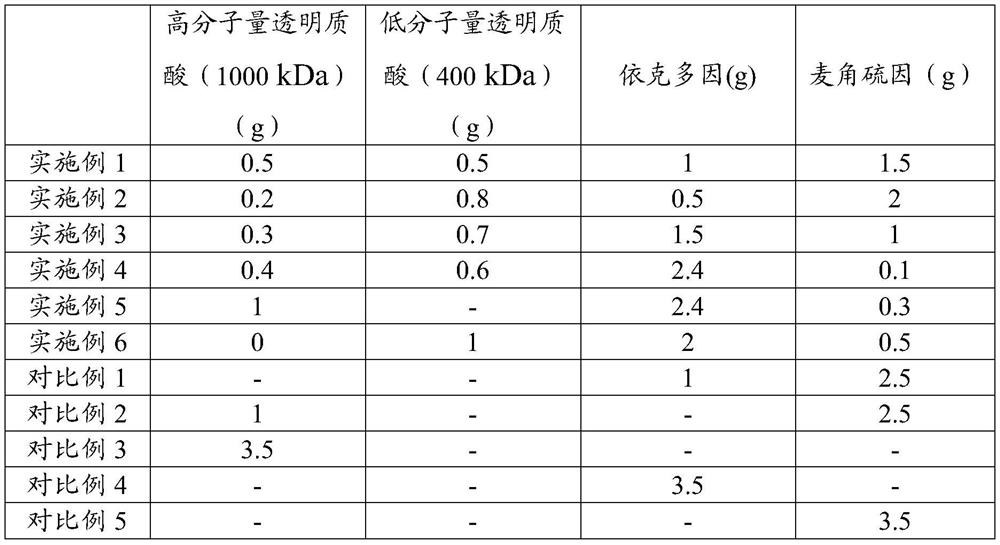

[0055] (1) Dissolve 1g of hyaluronic acid (including 0.5g of 1000kDa high molecular weight hyaluronic acid and 0.5g of 400kDa low molecular weight hyaluronic acid), 1g of ectoine, 1.5g of ergothioneine and 2g of pentanediol in 50ml Mix well in deionized water to obtain Phase A;

[0056] (2) Add 14g of polyvinyl alcohol into 50ml of deionized water, fully swell overnight, heat to 85°C to dissolve, cool, add 5g of chitosan and 1.5ml of glacial acetic acid when it cools to room temperature, stir at room temperature until completely dissolved, and finally Add 1 g of glycerin, stir and mix at room temperature to obtain phase B;

[0057] (3) Phase A and Phase B are mixed to obtain a colloid. The obtained colloid was sterilized at 121° C. for 8 minutes, and spread on a paraffin-coated and sterilized glass plate. Dry the glass plate at 45°C for 2.5 hours, then peel off the film, cut and pack to obtain the oral ulcer film.

Embodiment 2-6

[0059] Compared with Example 1, the difference of Examples 2-6 is that the addition amounts of high-molecular-weight hyaluronic acid, low-molecular-weight hyaluronic acid, ectoine and ergothioneine are different, and the specific addition amounts are shown in Table 1. Among them, the total amount of the three functional substances of hyaluronic acid, ectoine and ergothioneine is the same, 3.5g. Other operating steps and reaction conditions are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com