Foam carbon immobilization passivator as well as preparation method and application thereof

A technology of passivating agent and foamed carbon, which is applied in the field of foamed carbon materials, can solve the problems of unadjusted foamed carbon surface functional groups and mineral element content, increase the cost of foamed carbon preparation, etc., to improve the holding passivation performance and surface affinity Water-based, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

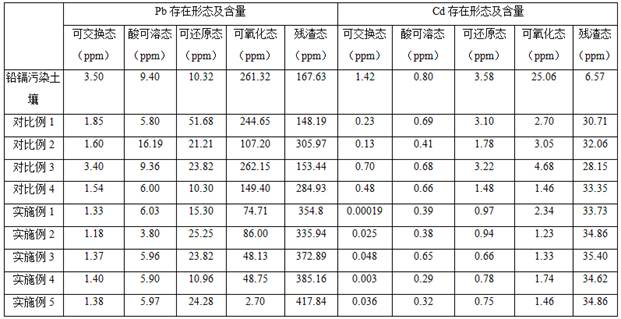

Examples

Embodiment 1

[0031] Embodiment 1: this foamed charcoal holding deactivator comprises the raw material of following weight portion: 40 parts of thermosetting phenolic resins, 60 parts of walnut shell-phenol liquefaction product resins, H 3 PO 4 10 parts, 3 parts of n-hexane, 7 parts of surfactant AEO-9, salt modifier KH 2 PO 4 8 parts, wherein the weight average molecular weight of the thermosetting phenolic resin is 15000, the viscosity is 1000mPa s, and the solid content is 54%, and the weight average molecular weight of the walnut shell-phenol liquefaction product resin is 428000, the viscosity is 280mPa s, and the solid content is 41.5%;

[0032] The preparation method of above-mentioned foamed carbon holding passivator is as follows:

[0033] (1) The weighed thermosetting phenolic resin, walnut shell-phenol liquefaction product resin, n-hexane, surfactant AEO-9, KH 2 PO 4 Add to the beaker in turn, stir and mix at 1100r / min for 2min with the help of a high-speed mixer, then add H ...

Embodiment 2

[0036] Embodiment 2: This foamed charcoal holding passivator comprises the following raw materials in parts by weight: 40 parts of urea-formaldehyde resin, 40 parts of sunflower stalk-phenol liquefaction product resin, 20 parts of ingot maple seed shell-phenol liquefaction product resin, 9 parts of oxalic acid, normal 3 parts of heptane, 8 parts of surfactant SPAN-40, salt modifier ZnCl 2 8 parts, wherein the weight average molecular weight of the urea-formaldehyde resin is 8154, the viscosity is 1100mPa·s, and the solid content is 54%, the weight average molecular weight of the sunflower straw-phenol liquefaction product resin is 249000, the viscosity is 400mPa·s, and the solid content is 45.7%; The weight average molecular weight of the phenol liquefaction product resin is 210000, the viscosity is 562mPa·s, and the solid content is 46.2%;

[0037] The preparation method of above-mentioned foamed carbon holding passivator is as follows:

[0038] (1) Put the weighed urea-form...

Embodiment 3

[0041] Embodiment 3: This foamed carbon holding passivator includes the following raw materials in parts by weight: 30 parts of phenol-formaldehyde-urea co-condensation resin, 70 parts of walnut shell-phenol liquefaction product resin, 10 parts of HCl, 3 parts of acetone, surfactant Tween 40 8 parts, salt modifier Na 2 C 2 o 4 8 parts, wherein the weight-average molecular weight of phenol-formaldehyde-urea polycondensation resin is 15000, the viscosity is 1558mPa·s, and the solid content is 57.9%, and the weight-average molecular weight of walnut shell-phenol liquefaction product resin is 330000, 466mPa·s, and the solid content is 50.3%;

[0042] The preparation method of above-mentioned foamed carbon holding passivator is as follows:

[0043] (1) The weighed phenol-formaldehyde-urea co-condensation resin, walnut shell-phenol liquefaction product resin, acetone, Tween 40, Na 2 C 2 o 4 Add it to a small beaker in turn, mix it at 1200r / min for 2.5 minutes with the help of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com