Multi-energy complementary large-scale intelligent pig raising industry ecologicalization mode

An ecological and intelligent technology, applied in the energy industry, biochemical instruments, biochemical equipment and methods, etc., to achieve the effect of reducing the amount of chemical fertilizers and pesticides, improving farmland soil, and enhancing self-sufficiency and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

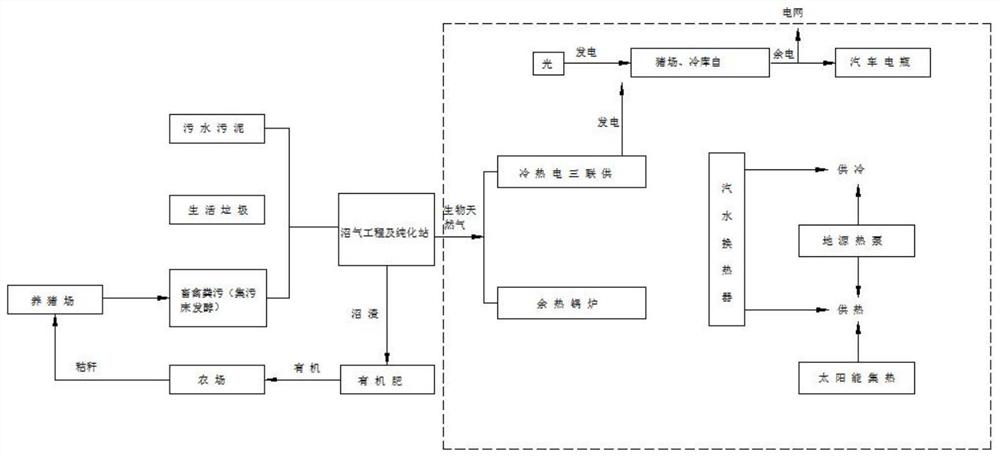

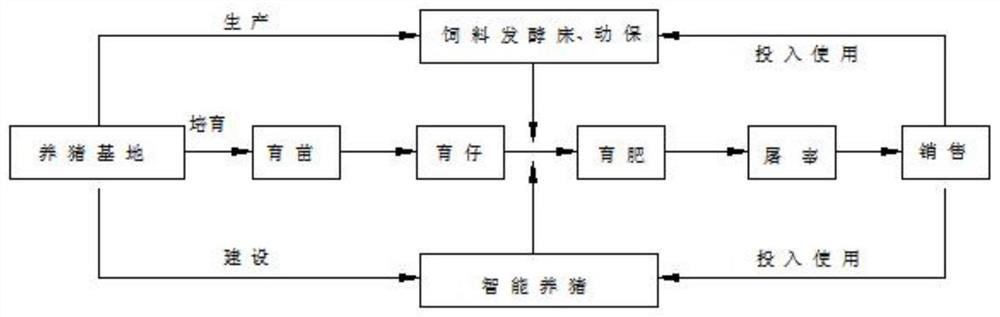

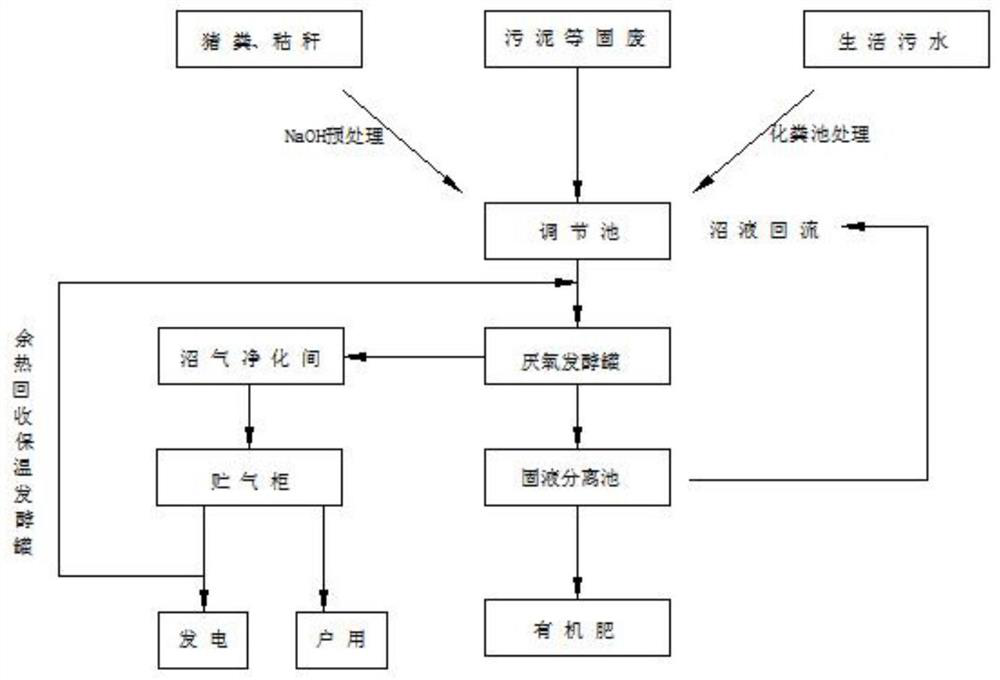

[0043] An ecological model of multi-energy complementary large-scale intelligent pig raising industry, including the following specific steps:

[0044] (1) Large-scale pig farms with a scale of 10,000 heads: the total scale is about 10,000 heads, and the self-propagation and self-supporting mode is adopted. ① The pig breeding base develops feed and heterotopic fermentation bed production, heterotopic fermentation bed design and biogas engineering pre-treatment system Combined into one; design feed additives, such as mechanized processing of high-protein feeds such as selenium-enriched citrus leaves and selenium-enriched earthworms, feed plus beneficial intestinal microorganisms and pig farm odor-removing microorganisms, greatly reducing ammonia nitrogen in pig farms to ensure healthy pig raising At the same time, it can speed up the growth of pigs; ② Utilize the straw, chaff, sawdust, etc. , upgraded to intelligent, closely combining intelligent technologies such as monitoring...

Embodiment 2

[0058] The heavy metal compound passivator for anaerobic fermentation of pig manure is mainly composed of biochar prepared from fungus residue and phosphate rock powder uniformly mixed at a mass ratio of 1:1;

[0059] Biochar is obtained by pyrolysis of waste fungus slag, which is obtained from discarded stropharia stropharia, phosphate rock powder is made by pulverizing phosphate rock, and the passivating agent is powdered. The preparation method of biochar includes The following steps:

[0060] (1) Dismantling the discarded Stropharia stropharia bag to obtain the slag;

[0061] (2) Place the fungus residue in a cool place to air-dry;

[0062] (3) Place the pretreated slag in a muffle furnace for pyrolysis

[0063] (4) Pulverize each pyrolysis product into granules and pass through a 100-mesh sieve for use as final granules with an average particle size of 0.5-1mm.

[0064] The heavy metal compound passivator used for anaerobic fermentation of pig manure and the fermentati...

Embodiment 3-5

[0066] The difference from Example 1 is that the proportions of the passivating agent accounted for by fungal residue biochar and phosphate rock powder are different, see Table 1 for details, and the preparation method and measurement method adopted are the same as in Example 1.

[0067] Passivator addition and passivator raw material composition in each embodiment of table 1

[0068]

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com