A pre-separation method and diamond-based separation device for fluorine-containing waste

A separation device and pre-separation technology, which can be used in electrical liquid separation, chemical instruments and methods, laboratory containers, etc., and can solve the problems of similar properties of by-products, difficult separation, and corrosion of analytical equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Example 1 Diamond-based separation device

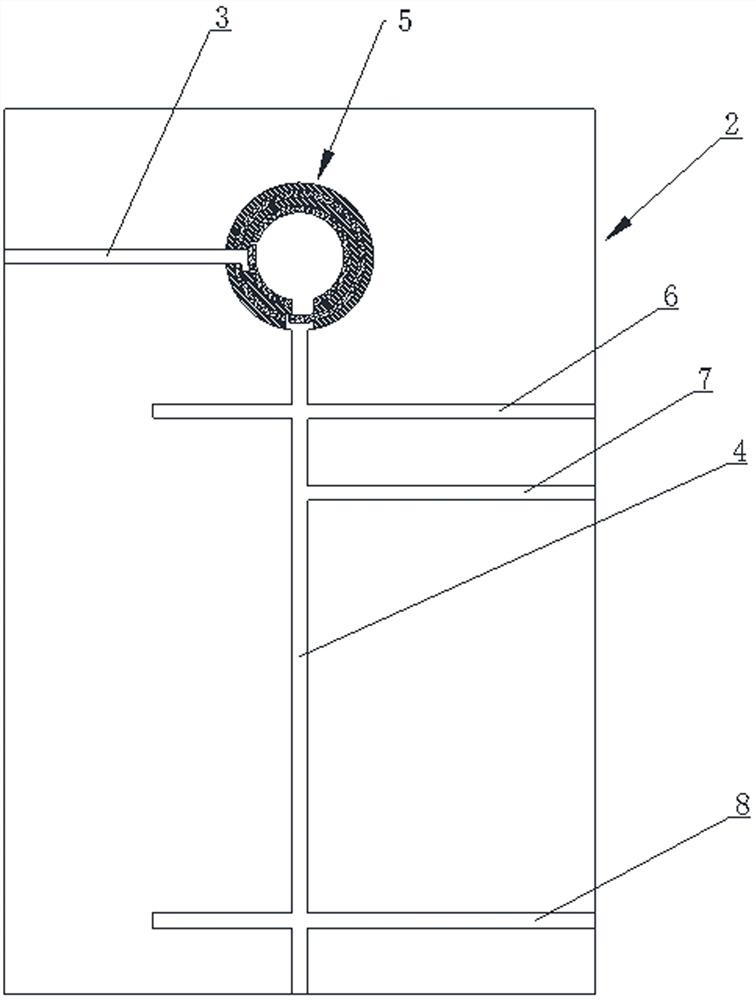

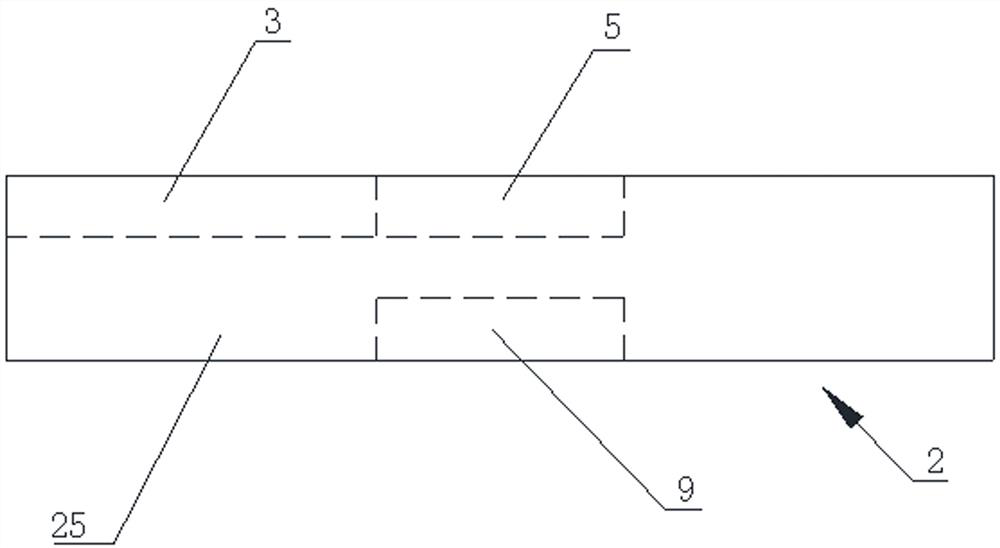

[0099] Such as Figure 1-6 As shown, the diamond-based separation device provided in this embodiment includes a separation chip, and the separation chip has an upper plate 1 and a lower plate 2 bonded to each other.

[0100] The lower sheet 2 is based on photosensitive glass-ceramics, and the side of the photosensitive glass-ceramic substrate 25 close to the upper sheet 1 is provided with a first liquid inlet channel 3, a main channel 4, and a micropump connecting the first liquid inlet channel 3 and the main channel 4 The cavity 5, the first electrode slot 6, the second electrode slot 8, the second liquid inlet channel 7 between the first electrode slot 6 and the second electrode slot 8, the first electrode and the second electrode are respectively formed in the second In the first electrode groove 6 and the second electrode groove 8, the first electrode groove 6, the second electrode groove 8 and the second liquid inlet cha...

Embodiment 2

[0113] Example 2 Preparation method of diamond-based separation device

[0114] The preparation method of the diamond-based separation device in this embodiment specifically includes the following steps:

[0115] 1) Prepare the next film:

[0116] 1.1) Preparation of photosensitive glass-ceramics

[0117] In parts by weight, the photosensitive glass-ceramic of the present embodiment comprises the following components: 72% SiO 2 , 6% Li 2 O, 15%Al 2 o 3 , 3% Ag 2 O, 3.5% CuO, and the rest is CeO 2 and SnO 2 . Prepared by sol-gel method.

[0118] 1.2) Preparation of microstructures on photosensitive glass-ceramics

[0119] Using a mask process, a microstructure including the first liquid inlet channel, the second liquid inlet channel, the main channel, the micropump cavity, the first electrode groove, and the second electrode groove, and the housing are opened on the photosensitive glass-ceramic substrate. cavity.

[0120] The parameters of the ultraviolet irradiatio...

Embodiment 3

[0157] Example 3 Preparation method of diamond-based separation device

[0158] The preparation method of the diamond-based separation device in this example is basically the same as that in Example 2, the difference lies in the method of preparing the helical coil in step 2.2). The preparation method of the helical coil in this example is as follows:

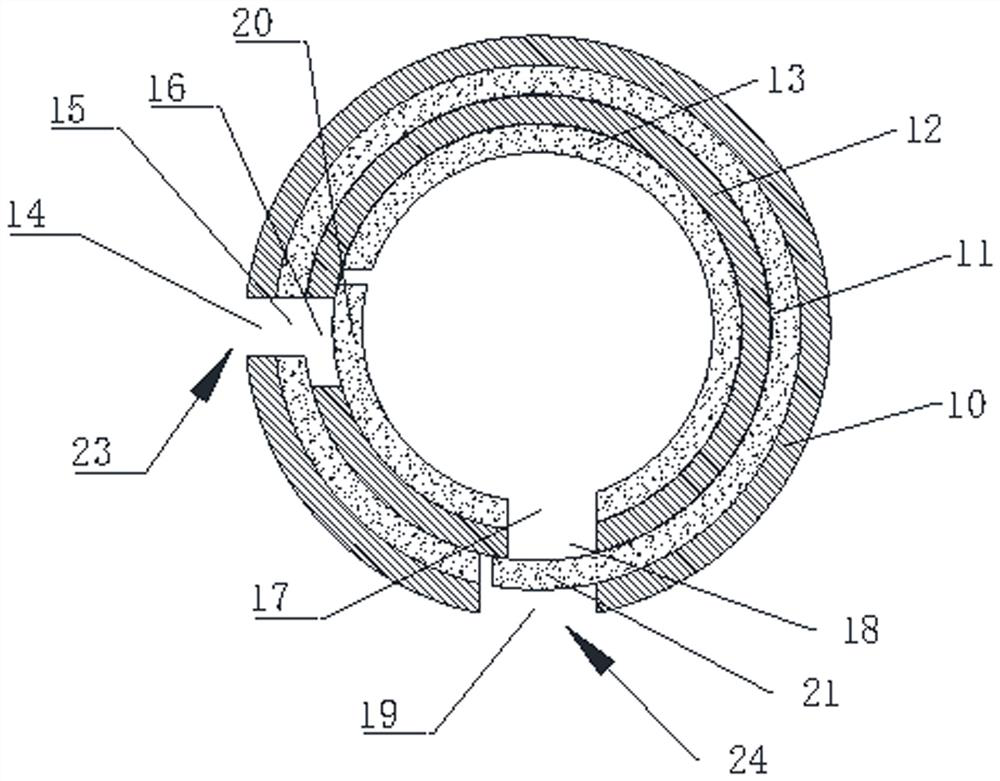

[0159] On the surface of the third diamond layer corresponding to the micropump cavity away from the silicon wafer, use the ion implantation process as in step 1.8) to implant boron into the third diamond layer to form boron-doped diamond in situ, and the implantation parameters can be the same as in step 1.8 ) remains the same. The single line width of boron-doped diamond is 50 μm, and the spacing is 50 μm.

[0160] Prepare a silicon dioxide insulating layer on the surface of the boron-doped diamond using the magnetron sputtering process as in step 1.3.1), and the thickness of the silicon dioxide insulating layer is 150 μm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com