Polyurethane foam surface-coupled β-cyclodextrin adsorption material and its preparation method and application

A technology of polyurethane foam and adsorption material, applied in the field of adsorption and separation, can solve the problems of high device price, non-reusability and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: Polyurethane foam surface coupling β -The preparation method of the adsorption material of cyclodextrin, concrete operation is as follows:

[0050] (1) Pretreatment of PUF: Cut the commercially available polyether PUF into a cuboid of 3×6×10cm, wash it with distilled water at 60°C for several times until the washing water is neutral, then dry it under vacuum at 60°C for 24 hours, and use fresh-keeping The film is tightly wrapped and placed in a desiccator for standby; the water absorption rate is measured W A 1665.1%, phenol adsorption Q 1 2.8mg / g;

[0051] (2) Amino release of PUF: Add 10 g of PUF cuboids with a size of about 3 × 3 × 0.2 cm in a beaker, and add the concentration of 2 moL / L of hydrochloric acid solution, seal the mouth of the beaker with plastic wrap, boil it in a boiling water bath for 1 hour, take out the product after the reaction and wash it repeatedly with distilled water until the washing liquid is neutral, flatten the product ...

Embodiment 2

[0057] Embodiment 2: Polyurethane foam surface coupling β -The preparation method of the adsorption material of cyclodextrin, the specific operation is: with the method of embodiment 1, only the volume mass ratio mL:g of hydrochloric acid solution and PUF in step (2) is adjusted to 30:1, and the concentration of hydrochloric acid solution is adjusted to 3 moL / L, the boiling time was adjusted to 3h, and the amination product PUF-NH 2 Amino content Am 0.4307mmol / g, water absorption W A 1698.2%, phenol adsorption Q 1 is 3.2mg / g; the step (3) β -The concentration of the CD aqueous solution was adjusted to 20g / L, and the addition amount was 27mL; 2mL of formaldehyde with a concentration of 37% by mass was added, and the reflux reaction time was adjusted to 5h; the PUF-NH 2 - β -CD product β - CD fixed capacity N 1 376.4mg / g, water absorption W A 2800.1%, phenol adsorption Q 1 It was 78.9 mg / g.

Embodiment 3

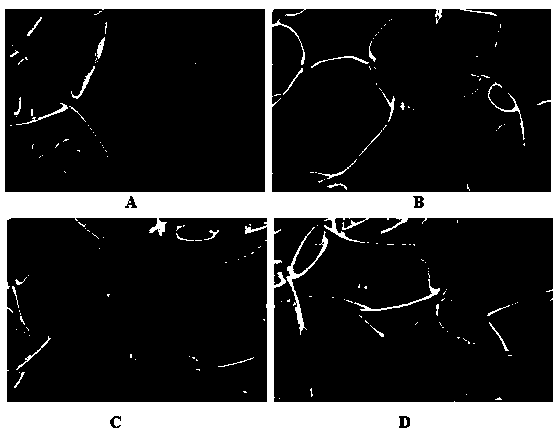

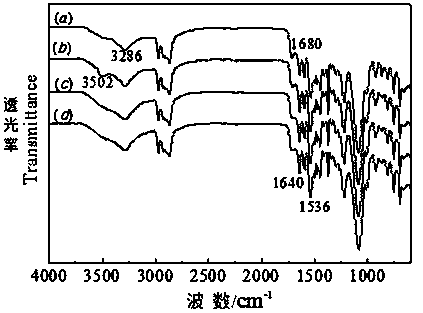

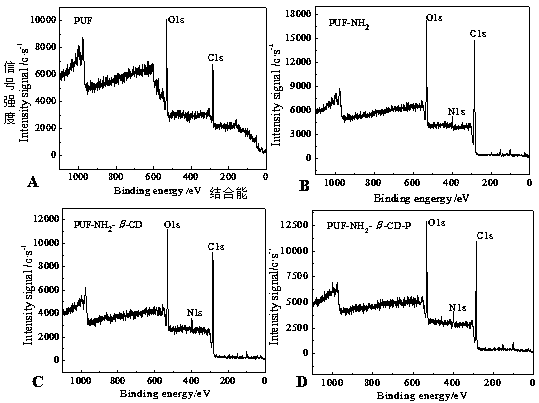

[0058] Embodiment 3: Polyurethane foam surface coupling β - Phenol adsorption material of cyclodextrin and its preparation method, the specific operation is: repeat Example 1, only adjust the volume-to-mass ratio of hydrochloric acid solution to PUF in step (2) to 50:1 (mL / g), boil time Adjusted to 4h; step (3) β -The concentration of the CD aqueous solution was adjusted to 30g / L, 3mL of formaldehyde with a concentration of 37% by mass was added, and the reflux reaction time was adjusted to 7h; the water absorption rate of PUF was measured W A 1665.1%, phenol adsorption Q 1 is 2.8mg / g, its SEM photo is shown in figure 1 A, ATR-FTIR spectrum see figure 2 In (a), XPS spectrum see image 3 A, the surface C content is 62.33%, the O content is 37.67%, and N is not detected. Measured its PUF-NH 2 Amino content Am 0.7870mmol / g, water absorption W A 1727.5%, phenol adsorption Q 1 is 3.4mg / g, its SEM photo is shown in figure 1 B, ATR-FTIR spectrum see figure 2 (b) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com