High-density culture method of lactobacillus helveticus, and preparation and application of high-activity bacterial powder

A technology of lactobacillus and high vigor, which is applied in the preparation of high vigor powder and high-density culture of Lactobacillus helveticus, which can solve the problems of long culture period and low vigor of fermentation broth, and achieve reduced fermentation cost and excellent adhesion Effects of shortening of performance and culture time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] 4. Preparation of freeze-dried bacteria powder: The collection method of bacteria slime, freeze-drying protective agent and freeze-drying process were optimized.

[0055] a. Sludge collection: adjust the pH of the fermentation broth obtained in the above step 3 to 6.0-7.0 with ammonia water, centrifuge at room temperature at 4000 rpm for 10-20 minutes, collect the sludge, and adjust the water content of the sludge to 70%-80%.

[0056] b. Addition of protective agent:

[0057] Based on the general protective agent formula in the laboratory (including lactose, skim milk, glycerin or sodium glutamate), the types and concentrations of different sugars, different concentrations of skim milk, different concentrations of glycerin and different concentrations of sodium glutamate, the addition of ascorbic acid , calcium chloride, yeast extract or glutathione concentration, and the pH of the freeze-drying protectant on the number of viable bacteria in the freeze-dried bacterial p...

Embodiment 1

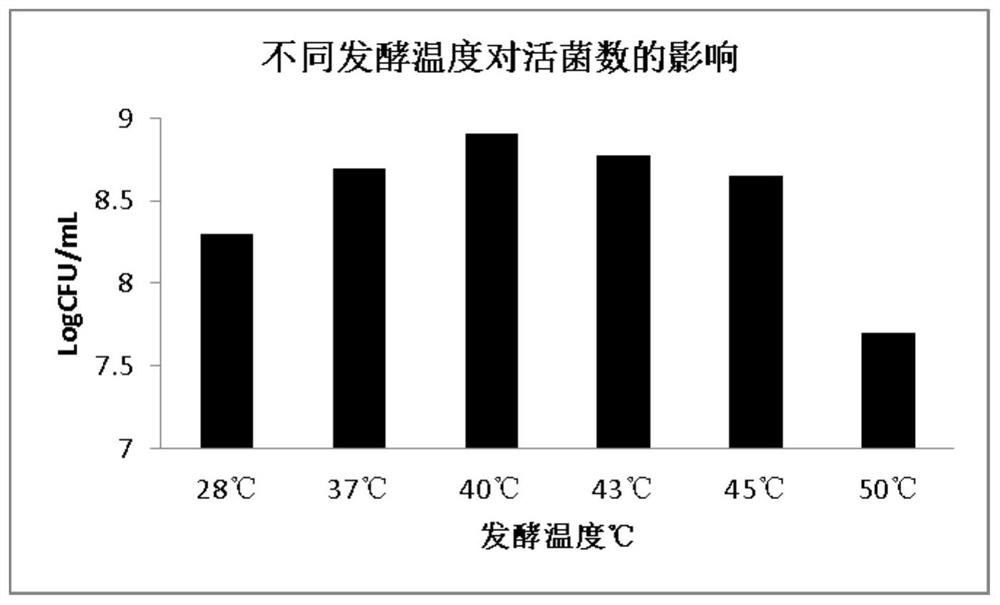

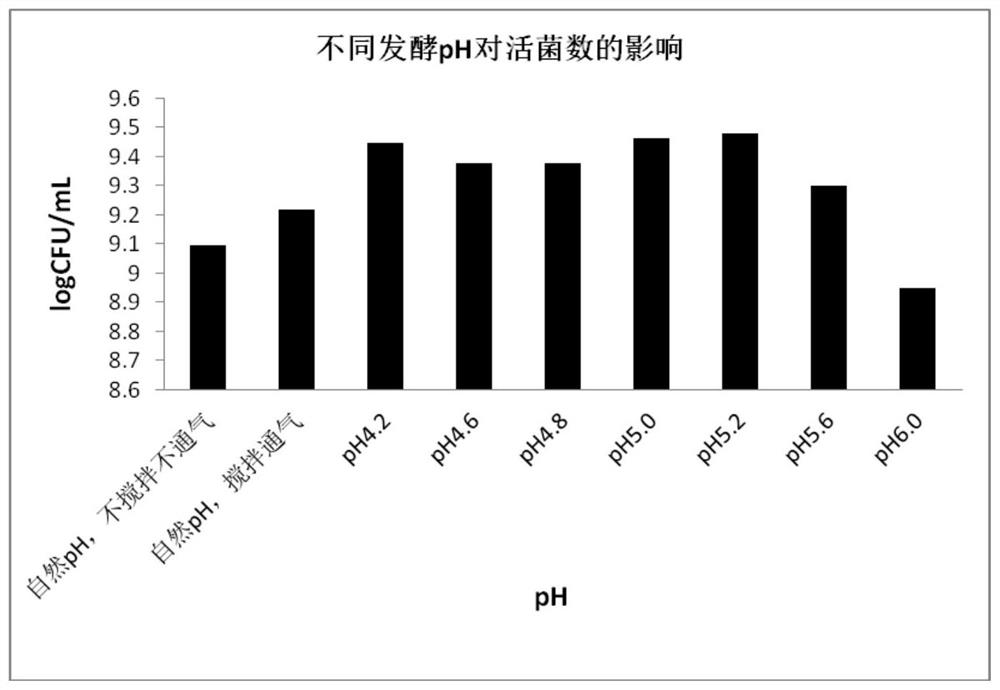

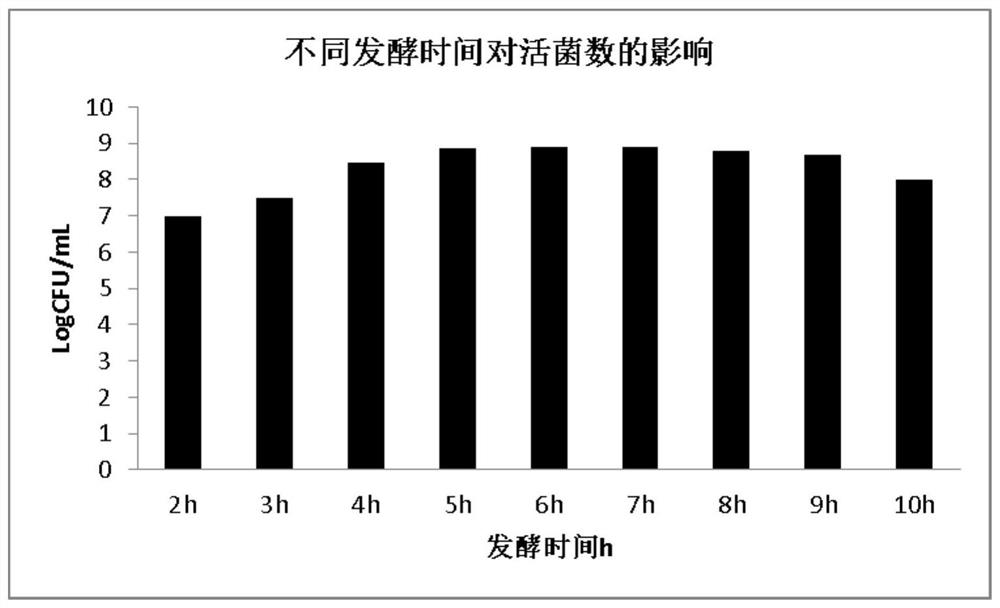

[0073] Dissolve 204g of whey powder, 28g of whey protein concentrate, 144g of soytone, 68g of concentrated tomato juice, 60g of yeast powder, 1.68g of manganese sulfate, 3.48g of magnesium sulfate, 18g of dipotassium hydrogen phosphate and 48g of sodium citrate in 5L of warm pure water , after cutting for 20-30 minutes, set the volume to 6L, and pour it into a 10L fermenter. Autoclave at 121°C for 10 minutes. After cooling to room temperature, the seed solution of Lactobacillus helveticus obtained in Example 1b was connected to a 10L fermenter at a 5% (v / v) inoculation amount. Fermentation temperature 40°C, CO2 2 , the stirring speed is controlled at 150rpm, the pH is controlled at 5.2 during fermentation, and the fermentation time is 6h. The number of live bacteria in the live bacteria fermented liquid obtained at this time was 5.50×109 cfu / mL. Adjust the pH of the fermentation broth to 6.8 with ammonia water, centrifuge at room temperature at 4000 rpm for 15 minutes, coll...

Embodiment 2

[0075] Dissolve 60g of whey powder, 28g of whey protein concentrate, 144g of soybean peptone, 68g of concentrated tomato juice, 60g of yeast powder, 1.68g of manganese sulfate, 3.48g of magnesium sulfate, 18g of dipotassium hydrogen phosphate and 48g of sodium citrate in 5L of warm pure water , after cutting for 20-30 minutes, set the volume to 6L, and pour it into a 10L fermenter. Autoclave at 121°C for 10 minutes. After cooling to room temperature, the seed solution of Lactobacillus helveticus obtained in Example 1b was connected to a 10L fermenter at a 5% (v / v) inoculation amount. Fermentation temperature 40°C, CO2 2 , the stirring speed is controlled at 150rpm, the pH is controlled at 5.2 during fermentation, and the fermentation time is 6h. The number of live bacteria in the live bacteria fermentation broth obtained at this time was 4.65×10 9 cfu / mL. The difference from Example 1 is that the addition amount of whey powder in the culture medium of this embodiment is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com