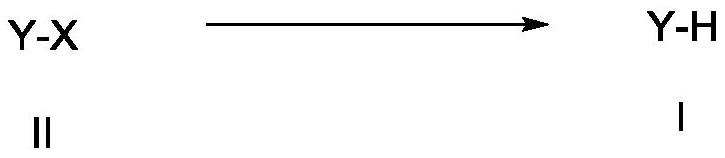

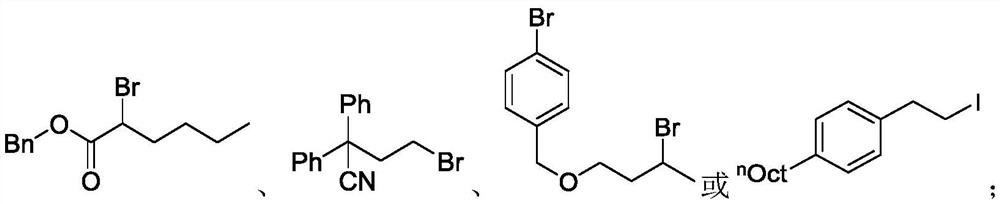

Method for hydrogenolysis of halides

A compound, halogen technology, applied in the field of halide hydrogenolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0108]

[0109] Under argon protection, 4-bromopiperidine hydrogen bromide (2.45g, 10mmol) was added successively to the reaction flask equipped with a stirring bar, pyridine (30mL) was fully dissolved, and p-toluenesulfonyl chloride (2.86 g, 15mmol), react at room temperature for 24h. Add deionized water to the system to quench the reaction, spin off a large amount of pyridine, extract the organic phase with 1M hydrochloric acid / dichloromethane, dry over anhydrous sodium sulfate, concentrate, and perform silica gel column chromatography. The eluent is petroleum ether: ethyl acetate: Dichloromethane=10:1:1 to 10:1:2, the product is 3.10 g of white solid, yield 97%, 1 H NMR purity greater than 98%. 1 H NMR (400MHz, CDCl 3 )δ7.65(d, J=8.0Hz, 2H), 7.34(d, J=8Hz, 2H), 4.25-4.24(m, 1H), 3.21-3.17(m, 2H), 3.10-3.09(m, 2H),2.45(s,3H),2.23-2.16(m,2H),2.09-2.01(m,2H); 13 C NMR (100MHz, CDCl 3 )δ143.69, 133.02, 129.72, 127.52, 47.79, 43.74, 34.61, 21.51.

preparation example 2

[0111]

[0112] Under argon protection, 2-indanol (1.34g, 10mmol), carbon tetrabromide (3.61g, 10.9mmol), and dichloromethane (50mL) were successively added to the reaction flask equipped with a stirring bar. After fully dissolving, the Under an ice bath, triphenylphosphine (dissolved in 10 mL of dichloromethane) (2.89 g, 11 mmol) was slowly added to the system. After the addition was complete, the reaction was returned to room temperature for 8 h, and the reaction was complete by TLC. Quenched with saturated sodium bicarbonate solution, extracted the organic phase with dichloromethane, dried over anhydrous sodium sulfate, and spin-dried, followed by silica gel column chromatography with petroleum ether as the eluent. The product was 1.51 g of a colorless liquid with a yield of 77%. 1H NMR (400MHz, CDCl 3 )δ7.26-7.19 (m, 4H), 4.78-4.73 (m, 1H), 3.50 (dd, J = 16.8Hz, 6.4Hz, 2H), 3.33 (dd, J = 16.8Hz, 4Hz, 2H); 13 C NMR (100MHz, CDCl 3 )δ140.48,126.94,124.50,49.57,44.59.IR(...

preparation example 3

[0114]

[0115] Under the air, add 5-methoxy-2-tetralone (3.52g, 20mmol) and methanol (100mL) successively to the egg-shaped bottle equipped with a stirrer. After fully dissolving, add boron to the system in four batches. Sodium hydride (907.9mg, 24mmol) was added within 15 minutes, reacted at room temperature for 2h, and the reaction was complete as detected by TLC. Saturated ammonium chloride solution was quenched, the organic phase was extracted with dichloromethane, dried over anhydrous sodium sulfate, concentrated, filtered through a short silica gel column, washed with dichloromethane, spin-dried, and directly used in the next reaction.

[0116] Under the protection of argon, add the above-mentioned crude product, carbon tetrabromide (7.23g, 21.8mmol), dichloromethane (100mL) to the reaction flask equipped with a stirring bar in sequence, after fully dissolving, add to the system under ice bath Slowly added triphenylphosphine (dissolved in 20 mL of dichloromethane) (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com