Synthesis method of ion pair reagent

The technology of an ion pair reagent and a synthesis method is applied in the field of ion pair reagent synthesis, which can solve the problems of low product purity, influence on chromatographic analysis results, and high product ultraviolet absorption signal, and achieve high purity, high yield, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

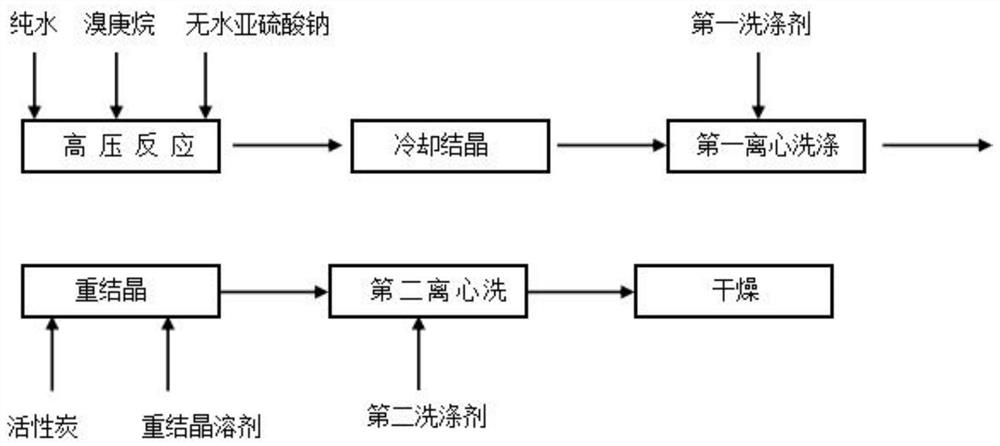

[0042] The invention provides a method for synthesizing an ion-pairing reagent. The ion-pairing reagent is sodium butanesulfonate, sodium pentanesulfonate, sodium hexanesulfonate, sodium heptanesulfonate, sodium octanesulfonate or decane Sodium alkanesulfonate, comprising the following steps:

[0043] (1) Under the condition of no catalyst, water, sodium sulfite and brominated alkanes are mixed for high-pressure reaction to obtain product feed liquid; the temperature of the high-pressure reaction is 180-300° C., and the pressure is 10-15 kg;

[0044] (2) directly cooling and crystallizing the product feed liquid, and performing first washing on the obtained solid to obtain a crude product;

[0045] (3) The crude product is recrystallized, and the obtained recrystallized product is sequentially subjected to second washing and drying to obtain an ion-pairing reagent.

[0046] In the present invention, under the condition of no catalyst, water, sodium sulfite and brominated alka...

Embodiment 1

[0070] (1) Add 5000g of pure water, 900g of anhydrous sodium sulfite and 1500g of 1-bromoheptane into the autoclave, heat to 200°C, keep the pressure at 13kg, and react for 6 hours.

[0071] (2) After the reaction is over, pump the product liquid into the glass crystallization tank, turn on the stirring device, control the stirring speed at 10rpm, control the crystallization temperature at 2-6°C, and the crystallization time for 3h, and pump the crystallization liquid with a suction filter bottle Dried, then centrifuged at high speed, washed 3 times with n-hexane during centrifugation, using 500mL of n-hexane each time, and collected 1560g of crude sodium heptanesulfonate.

[0072] (3) Take 1560g of the crude product and put it into a glass reactor, add 5000g of absolute ethanol and 850g of pure water, heat and stir to dissolve, the dissolution temperature is controlled between 80-100°C, after the crude product is completely dissolved, add 8g of activated carbon, and stir for 1...

Embodiment 2

[0080] (1) Add 4000g of pure water, 900g of anhydrous sodium sulfite and 1000g of 1-bromopentane into the autoclave, heat to 195°C, keep the pressure at 10kg, and react for 5 hours.

[0081] (2) After the reaction is over, pump the product liquid into the glass crystallization tank, turn on the stirring device, control the stirring speed at 10rpm, control the crystallization temperature at 2-6°C, and the crystallization time for 4h, and pump the crystallization liquid with a suction filter bottle Dry, then centrifuge at high speed to dry, wash with petroleum ether 3 times during centrifugation, use petroleum ether 500mL each time, collect 1310g of crude sodium pentanesulfonate.

[0082] (3) Take 1310g of the crude product and put it into a glass reactor, add 5000g of absolute ethanol and 850g of pure water, heat and stir to dissolve, the dissolution temperature is controlled between 80-100°C, after the crude product is completely dissolved, add 5g of activated carbon, and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com