Multifunctional coating for centralized area of electrical equipment and preparation method thereof

An electrical equipment, multi-functional technology, applied in radiation-absorbing coatings, anti-corrosion coatings, coatings, etc., can solve problems such as irritation to the lungs, resistance to resistance, etc., and achieve the effects of long durability, normal operation avoidance, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

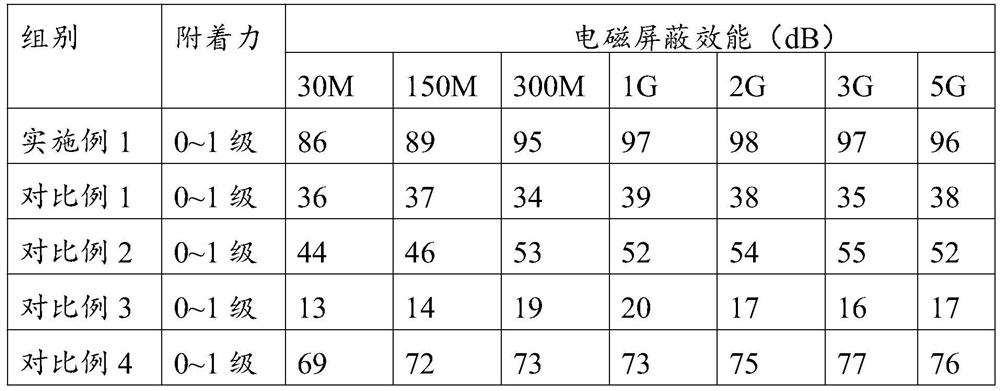

Examples

Embodiment 1

[0045] The present embodiment provides a kind of multi-functional paint that is used for the concentrated area of electrical equipment, and it comprises the following components:

[0046] 0.05 parts by mass of absorbing material, 20 parts by mass of diatomaceous earth, 70 parts by mass of HPMC, 3 parts by mass of ordinary aluminum silicate fiber, 1.5 parts by mass of nano-platinum powder, 1.5 parts by mass of conductive micropowder (nanoscale SnO 2 powder), 30 parts by mass of white cement, 10 parts by mass of Wacker rubber powder, and 12 parts by mass of PVB. The above-mentioned powders are mixed in the trough, and mixed by microwave vibration. Before use, add water, disperse evenly in the high-speed disperser, and discharge the material to obtain slurry, which can be used for construction. If the slurry has been left to stand for a long time before use, ultrasonic vibration homogenization treatment is required before official use, and the following examples and comparative...

Embodiment 2

[0048] The present embodiment provides a kind of multi-functional paint that is used for the concentrated area of electrical equipment, and it comprises the following components:

[0049] 0.05 parts by mass of absorbing material, 15 parts by mass of diatomaceous earth, 40 parts by mass of HBMC, 3 parts by mass of forsterite fiber, 1 part by mass of nano-platinum powder, 1 part by mass of conductive micropowder (nanoscale SnO 2 powder), 25 parts by mass of white cement, 10 parts by mass of Wacker rubber powder, and 10 parts by mass of PVB. The above-mentioned powders are vibrated by microwaves and mixed to form a radiation-proof coating that can be conveniently applied. Water is added before use, and they are evenly dispersed in a high-speed disperser, and the slurry is obtained after discharge, which can be used for construction.

Embodiment 3

[0051] The present embodiment provides a kind of multi-functional paint that is used for the concentrated area of electrical equipment, and it comprises the following components:

[0052] 0.04 parts by mass of absorbing material, 10 parts by mass of diatomite, 3 parts by mass of expanded vermiculite, 3 parts by mass of expanded perlite, 60 parts by mass of HPMC, 3 parts by mass of polycrystalline alumina fiber, 3 parts by mass of Parts of nano-platinum powder, 2 parts by mass of conductive powder (nanoscale SnO 2 micropowder), 35 parts by mass of white cement, 12 parts by mass of Wacker rubber powder, and 12 parts by mass of PVB adhesive. The above-mentioned powders are vibrated by microwaves and mixed to form a radiation-proof coating that can be conveniently applied. Water is added before use, and they are evenly dispersed in a high-speed disperser, and the slurry is obtained after discharge, which can be used for construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com