Antibacterial, mildew-proof and antiviral electrophoretic stainless steel and preparation method thereof

An antibacterial and mildew proof, stainless steel technology, applied in the fields of botanical equipment and methods, electrophoretic plating, disinfectants, etc., can solve the problems of thin surface film layer and low antibacterial performance, and achieve good killing effect, low cost, combined with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

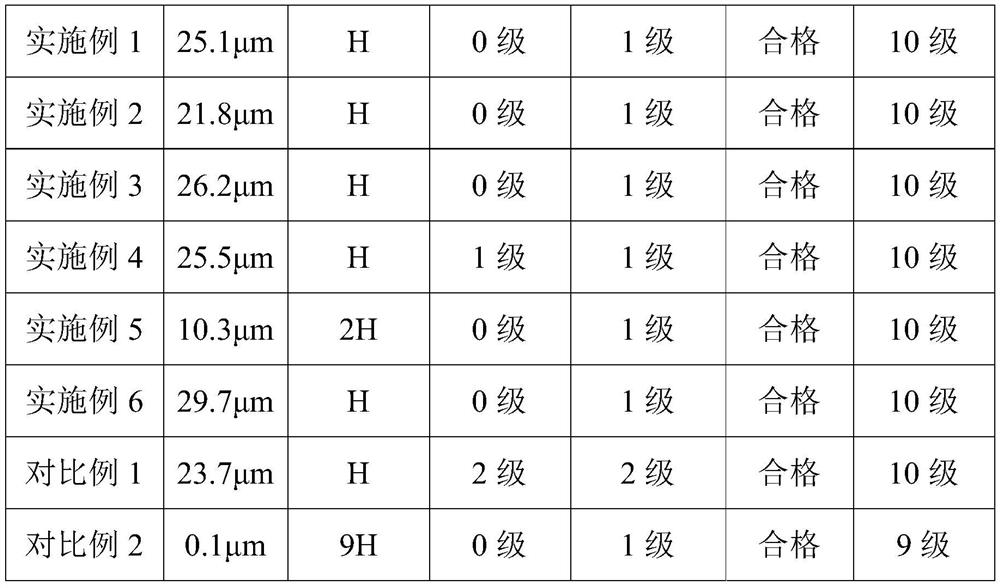

Examples

Embodiment 1

[0079] This embodiment provides a method for preparing antibacterial, anti-mildew and anti-virus electrophoresis stainless steel, the preparation method includes the following steps:

[0080] (1) Alkaline cleaning and degreasing treatment: put the stainless steel into the lye, stir it, and control the temperature to 80°C for 10 minutes, then take out the stainless steel and put it into water for washing, and apply ultrasound. And control the water temperature to 25°C for 8 minutes;

[0081] Wherein, the lye includes sodium hydroxide 60g / L, sodium carbonate 30g / L, sodium phosphate 20g / L and sodium silicate 7.5g / L, and the rest is water;

[0082] (2) Electropolishing treatment: the stainless steel after the alkaline cleaning and degreasing treatment described in step (1) is put into the polishing liquid, with the stainless steel as the anode and the graphite as the cathode, apply direct current, and control the current density to be 50A / dm 2 , the temperature is 50°C, the tim...

Embodiment 2

[0093] This embodiment provides a preparation method of antibacterial, mildew-proof and anti-virus electrophoresis stainless steel, except that the "primary antibacterial agent" in the anodic oxidation solution described in step (4) is omitted, that is, the "silver nitrate as a primary antibacterial agent 0.5 g / L " is omitted, and other conditions are exactly the same as in Example 1.

Embodiment 3

[0095]This embodiment provides a kind of preparation method of antibacterial, mildew-proof and anti-virus electrophoresis stainless steel, except that the "secondary antibacterial agent" in the cathodic electrophoresis liquid described in step (5) is omitted, that is, the "nitric acid as a secondary antibacterial agent" Silver 0.3% and quaternary ammonium salt bactericide 0.2% " omission, other conditions and embodiment 1 are identical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com