Ultrahigh-toughness biosafety excrement leaking plate

A biosafety, ultra-high toughness technology, applied in animal houses, animal husbandry, applications, etc., can solve the problems of inconvenient installation and transportation, poor durability, heavy weight, etc., and achieve high cost performance, increased durability, and dense products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

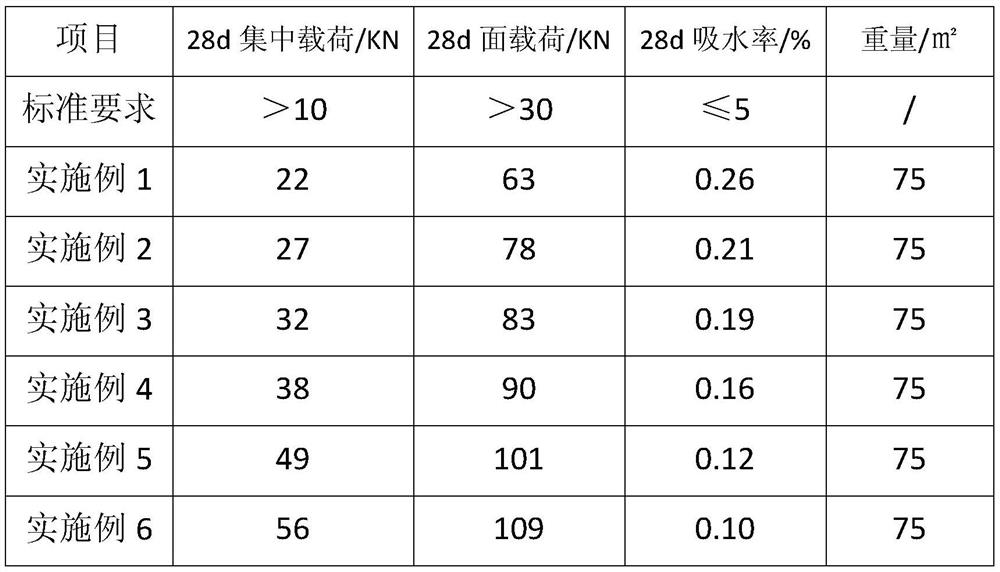

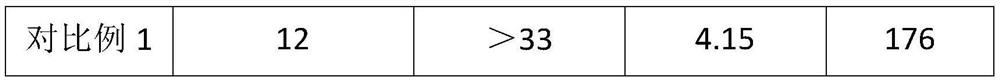

Embodiment 1

[0022] An ultra-high toughness biosafety leaking dung board is composed of the following components in terms of mass percentage: 46.5% of river sand, 10% of airgel, 11% of mineral powder, 25.82% of cement, 0.09% of polyepoxysuccinic acid, water reducing Agent 0.59%, polyoxymethylene fiber 6%.

[0023] Put the above components into a mixer, then add 9.5% water of the total mass of the above components and stir evenly to obtain a super high toughness composite fiber cement-based material slurry; pour the slurry into a special mold equipped with a steel frame, Reinforcement is 5.4kg per square meter; after hardening, it is cured at room temperature for 28 days to obtain an ultra-high toughness biosafety leaking dung board.

Embodiment 2

[0025] An ultra-high toughness biosafety leaking dung board, which is composed of the following components in terms of mass percentage: 46.5% of river sand, 10% of airgel, 11% of mineral powder, 25.73% of cement, 0.09% of polyepoxysuccinic acid, ethylene glycol 0.09% sodium amine di-o-phenylacetate, 0.59% superplasticizer, 6% polyoxymethylene fiber.

[0026] Put the above components into a mixer, then add 9.5% water of the total mass of the above components and stir evenly to obtain a super high toughness composite fiber cement-based material slurry; pour the slurry into a special mold equipped with a steel frame, Reinforcement is 5.4kg per square meter; after hardening, it is cured at room temperature for 28 days to obtain an ultra-high toughness biosafety leaking dung board.

Embodiment 3

[0028] An ultra-high toughness biosafety leaking dung board, which is composed of the following components in terms of mass percentage: 46.5% of river sand, 11% of airgel, 11% of mineral powder, 23.73% of cement, 0.09% of polyepoxysuccinic acid, ethylene glycol 0.09% sodium amine di-o-phenylacetate, 0.59% superplasticizer, 6% polyoxymethylene fiber.

[0029] Put the above components into a mixer, then add 9.5% water of the total mass of the above components and stir evenly to obtain a super high toughness composite fiber cement-based material slurry; pour the slurry into a special mold equipped with a steel frame, Reinforcement is 5.4kg per square meter; after hardening, it is cured at room temperature for 28 days to obtain an ultra-high toughness biosafety leaking dung board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com