Halogen salt modified composite solid electrolyte as well as preparation method and application thereof

A technology of solid electrolyte and solid electrolyte membrane, which is applied in the direction of composite electrolyte, electrolyte storage battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve problems such as difficult formation of lithium-conducting channels, achieve widening electrochemical stability window, improve chemical stability, and prevent The effect of battery overcharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

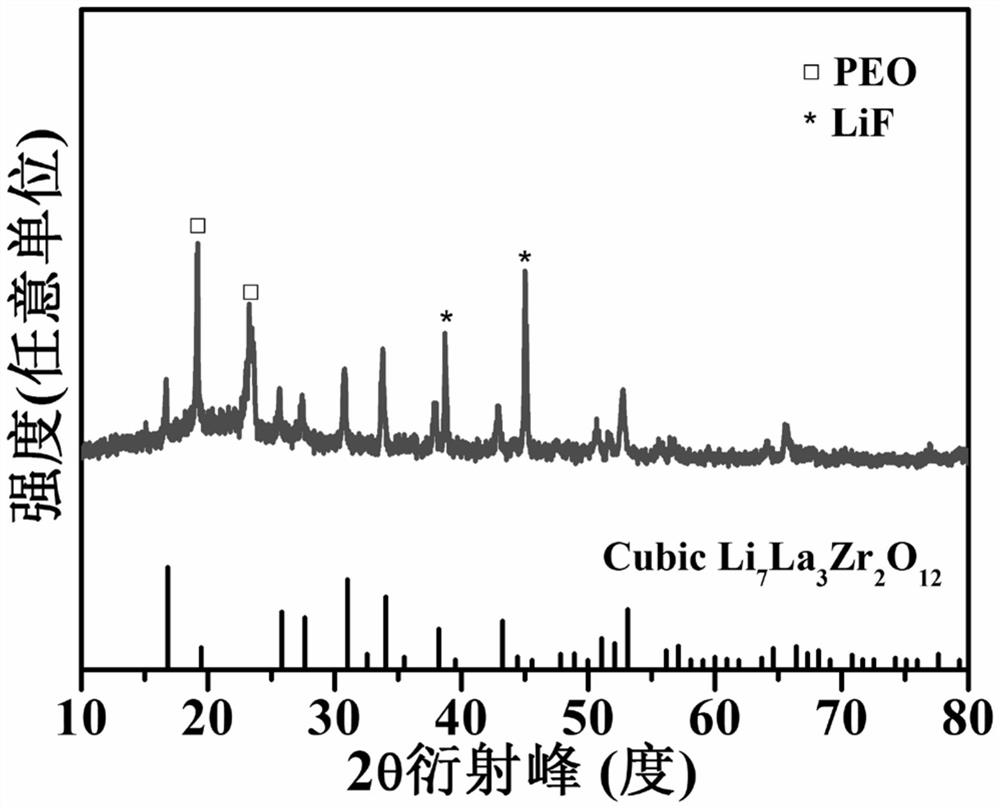

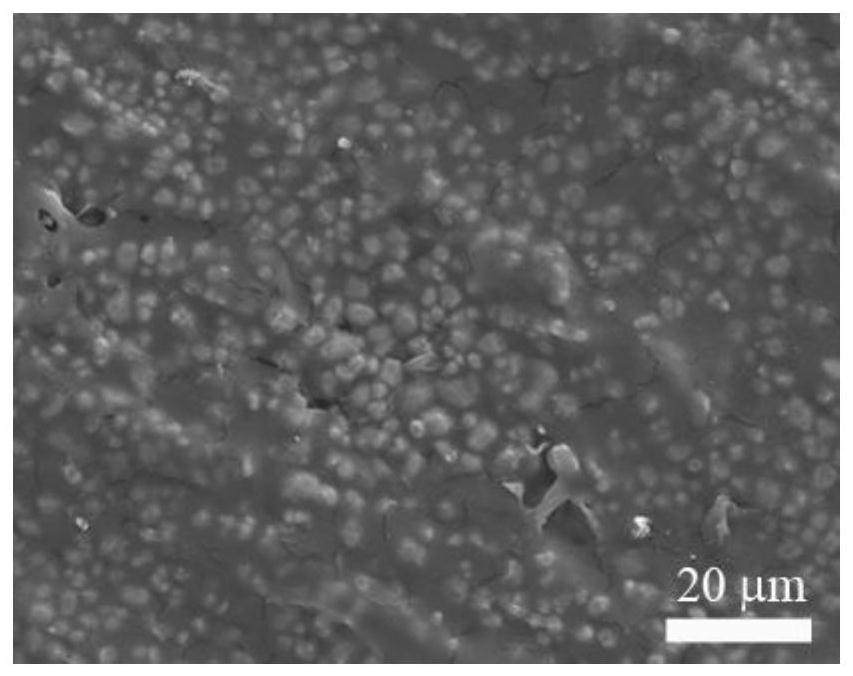

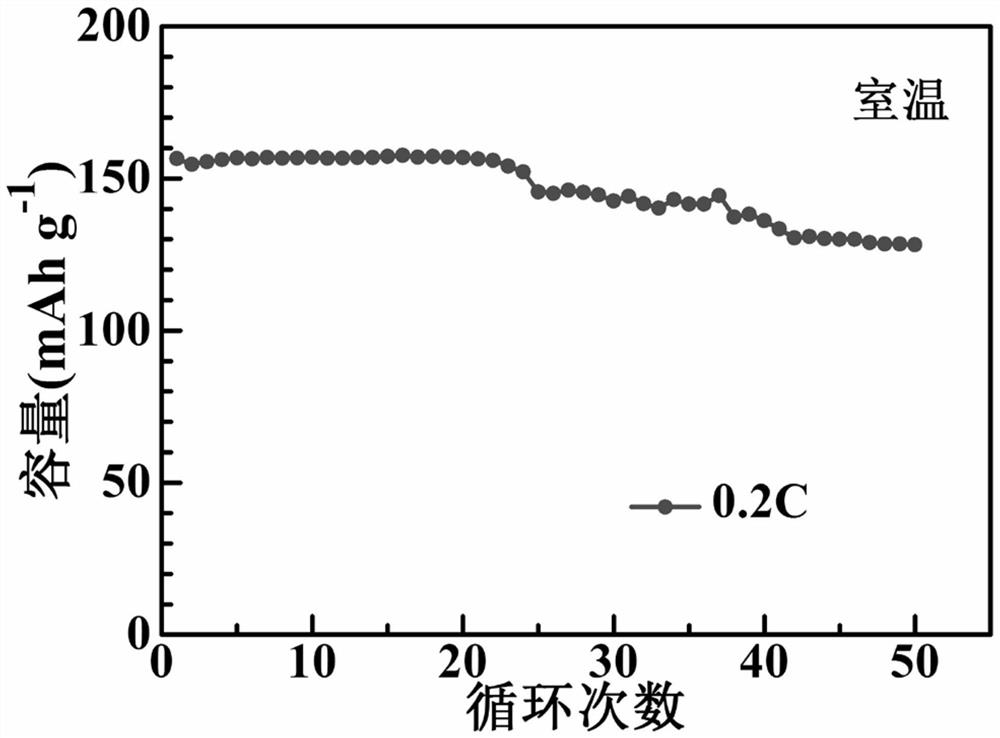

[0040] A halide-salt-modified composite solid-state electrolyte composed of Li 6.4 La 3 Zr 2 Al 0.2 o 12 Nanofibers, polyethylene oxide PEO, polypropylene carbonate PPC, lithium bistrifluoromethanesulfonimide LiTFSI and LiF. The thickness is 50 μm, and the ionic conductivity at room temperature is 7.6×10 -4 S / cm.

[0041]Among them Li 6.4 La 3 Zr 2 Al 0.2 o 12 The mass ratio of nanofibers in the composite solid electrolyte is 40%.

[0042] The mass ratio of polypropylene carbonate PPC in the composite solid electrolyte is 24%.

[0043] The mass ratio of polyethylene oxide PEO in the composite solid electrolyte is 24%.

[0044] The mass ratio of lithium bistrifluoromethanesulfonimide LiTFSI in the composite solid electrolyte is 9%.

[0045] The mass ratio of LiF in the composite solid electrolyte is 3%.

[0046] A method for preparing a halogen-salt-modified composite solid electrolyte, the specific preparation method is as follows: including the preparation of ga...

Embodiment 2

[0063] A halide-salt-modified composite solid-state electrolyte composed of Li 6.75 La 3 Zr 1.75 Nb 0.25 o 12 Nanofiber, polyethylene oxide PEO, polypropylene carbonate PPC, lithium perchlorate LiClO 4 and LiCl composition. The thickness is 100 μm, and the ionic conductivity at room temperature is 2.3×10 -4 S / cm.

[0064] Among them Li 6.75 La 3 Zr 1.75 Nb 0.25 o 12 The mass ratio of nanofibers in the composite solid electrolyte is 10%.

[0065] The mass ratio of polypropylene carbonate PPC in the composite solid electrolyte is 14%.

[0066] The mass ratio of polyethylene oxide PEO in the composite solid electrolyte is 60%.

[0067] Lithium perchlorate LiClO 4 The mass ratio in the composite solid electrolyte is 15%.

[0068] The mass ratio of LiCl in the composite solid electrolyte is 1%.

[0069] A method for preparing a halogen-salt-modified composite solid-state electrolyte, the specific preparation method is as follows: including the preparation of garnet-...

Embodiment 3

[0086] A halide-salt-modified composite solid-state electrolyte composed of Li 5.5 La 3 Zr 2 Ga 0.5 o 12 Nanofiber, polyethylene oxide PEO, polypropylene carbonate PPC, lithium difluorooxalate borate LiDFOB and LiBr. The thickness is 300 μm, and the ionic conductivity at room temperature is 5.9×10 -4 S / cm.

[0087] Among them Li 5.5 La 3 Zr 2 Ga 0.5 o 12 The mass ratio of nanofibers in the composite solid electrolyte is 60%.

[0088] The mass ratio of polypropylene carbonate PPC in the composite solid electrolyte is 10%.

[0089] The mass ratio of polyethylene oxide PEO in the composite solid electrolyte is 5%.

[0090] The mass ratio of lithium difluorooxalate borate LiDFOB in the composite solid state electrolyte is 20%.

[0091] The mass ratio of LiBr in the composite solid electrolyte is 5%.

[0092] A method for preparing a halogen-salt-modified composite solid-state electrolyte, the specific preparation method is as follows: including the preparation of garne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com