Method for constructing Z-type heterojunction photo-anode and Z-type heterojunction photo-anode

A photoanode and heterojunction technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve problems such as dangerous synthesis conditions, complex preparation process, and obstacles to the industrial application process of photocatalysts, so as to achieve simple operation and improve photoresponse current , the effect of promoting the charge separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

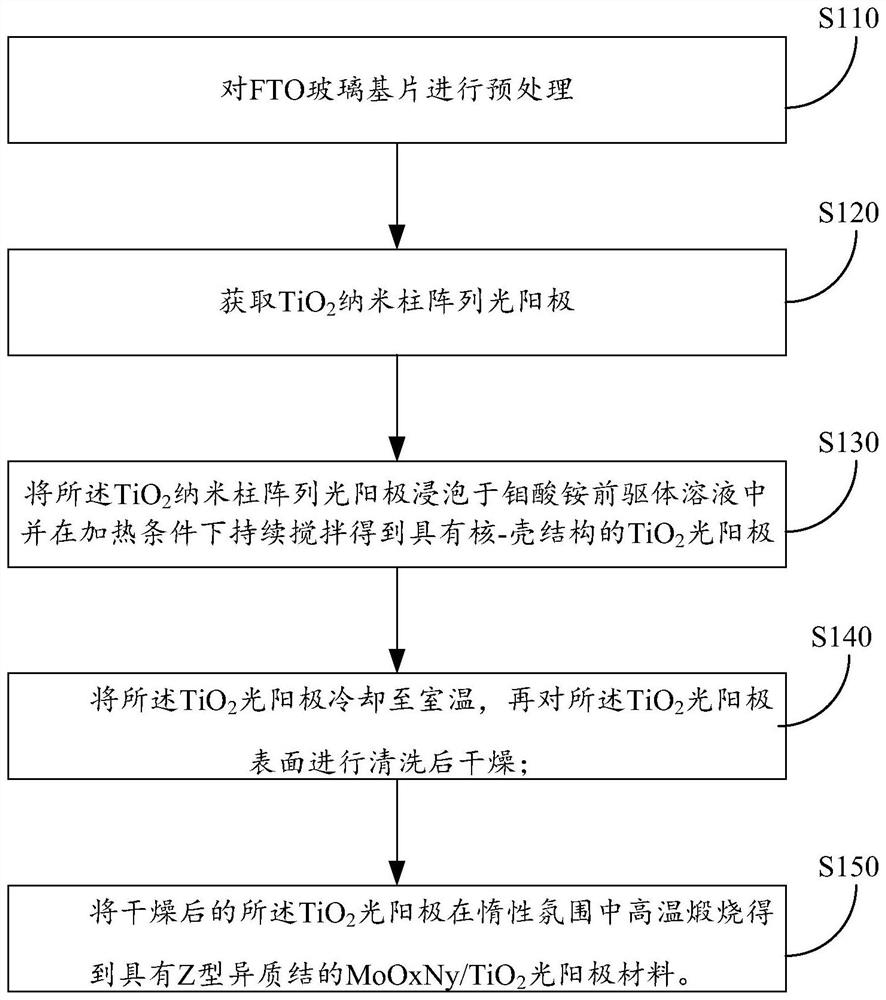

[0075] Core-shell structure TiO 2 Fabrication of nanopillar array photoanodes

[0076] (1) Carry out pretreatment to FTO glass substrate, specifically comprise the following steps:

[0077] a. Cut the FTO glass substrate to 2×4cm using a glass knife 2 size;

[0078] b. Immerse the cut FTO glass substrate in a 1:1 mixed solution of acetone and absolute ethanol, and sonicate for 15 minutes;

[0079] c. Soak the FTO glass substrate in a 3:1 mixed solution of hydrogen peroxide and concentrated sulfuric acid, and let it stand for 10 minutes;

[0080] d. Then immerse the FTO glass substrate in absolute ethanol and let it stand for 15 minutes;

[0081] e. Finally, use high-purity nitrogen (N 2 , 99.999%) dry the FTO glass substrate.

[0082] (2) Add 20ml of deionized water, 20ml of concentrated hydrochloric acid and 0.5ml of tetrabutyl titanate into a beaker, and stir at room temperature for 30min to obtain a mixed solution;

[0083](3) Put the conductive surface of the FTO gl...

Embodiment 2

[0088] A construction strategy of a Z-shaped heterojunction photoanode

[0089] (A) will be prepared by the TiO obtained by embodiment 1 method 2 The photoanode is immersed in the ammonium molybdate precursor solution prepared by dissolving 100mg ammonium molybdate tetrahydrate powder in 100ml deionized water as the base solvent, and continuously stirred at 100r / min at 70°C for 2h;

[0090] (B) TiO obtained by the above step (A) 2 Cool the photoanode to room temperature, clean its surface with absolute ethanol and deionized water, and dry the material in an oven at 80°C for 30 minutes;

[0091] (C) TiO after the above step (B) is processed 2 The photoanode was calcined at 300 °C for 1 h in an argon atmosphere in a tube furnace to obtain MoO with a special Z-type heterojunction x N y / TiO 2 Photoanode material.

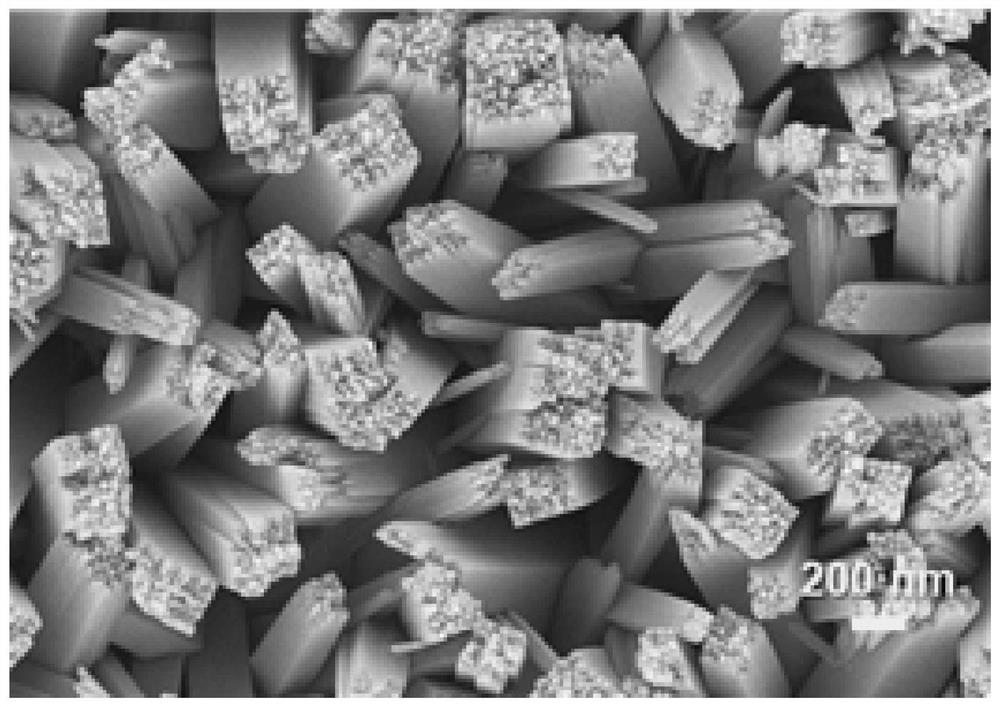

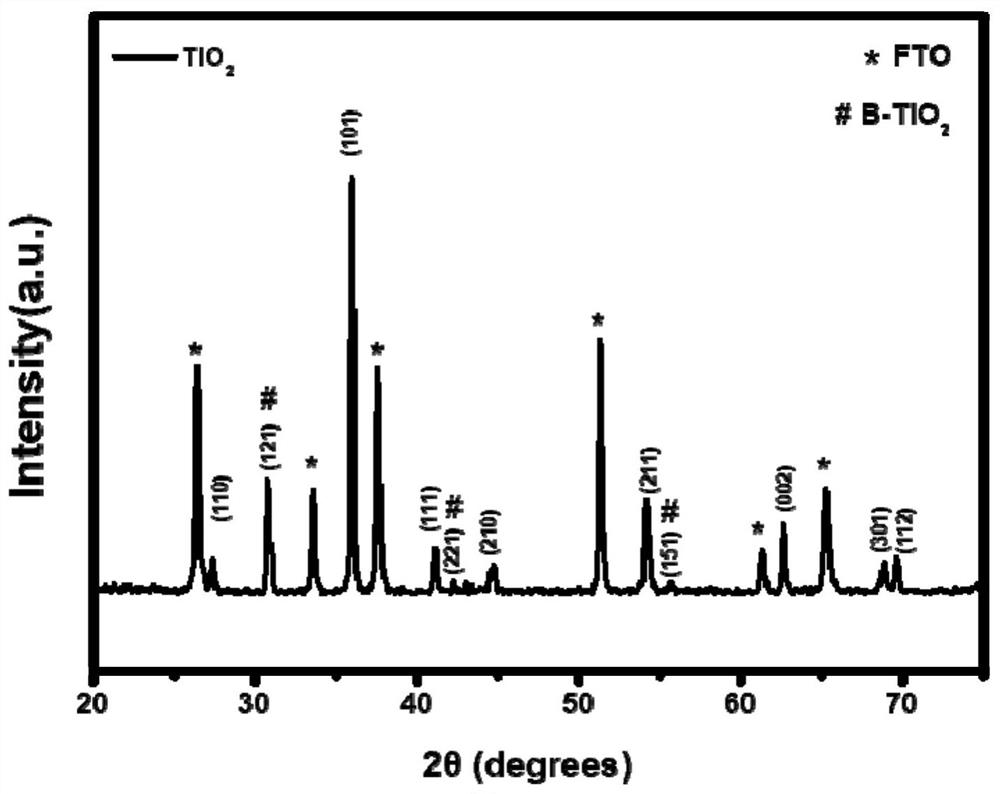

[0092] Such as Figure 4 As shown, MoO x N y / TiO 2 The lattice constant measured inside the photoanode is 0.325nm, which corresponds to the (110) plane of t...

Embodiment 3

[0095] Z-type heterojunction MoO x N y / TiO 2 Photoanodic photoelectrochemical testing

[0096] 1. All photoelectrochemical measurements were performed using a CHI660e potentiostat at room temperature in a typical three-electrode cell, where the photoanode (the sample prepared above) was used as the working electrode, Pt foil was used as the counter electrode, and Ag / AgCl was used as the reference electrode.

[0097] 2. The electrolyte is 0.5M Na 2 SO 4 , buffered to pH 7.

[0098] 3. The prepared TiO 2 and MoO x N y / TiO 2 The photoanode is cut to 1×2cm 2 Electrode sheet, inserted into the electrolyte, the test area is 1×1cm 2 .

[0099] 4. Use the peccell PEC-L01 solar simulator integrated with a 100W xenon arc lamp and AM 1.5 filter to perform photoelectrochemical measurements under a simulated sunlight illumination.

[0100] 5. For photocurrent measurement, use linear sweep voltammetry (LSV) and keep the sweep rate at 0.05V / s.

[0101] 6. According to the Nern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap