Catalyst for preparing propylene through methanol conversion and preparation method and application thereof

A methanol conversion and catalyst technology, applied in catalyst activation/preparation, carbon compound catalyst, physical/chemical process catalyst, etc., can solve the adverse effects of ZSM-5 molecular sieve catalytic performance, insufficient to support industrial production applications, molecular sieve structure damage, etc. problems, to achieve the effect of shortened residence time, high propylene selectivity, and reduced coking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

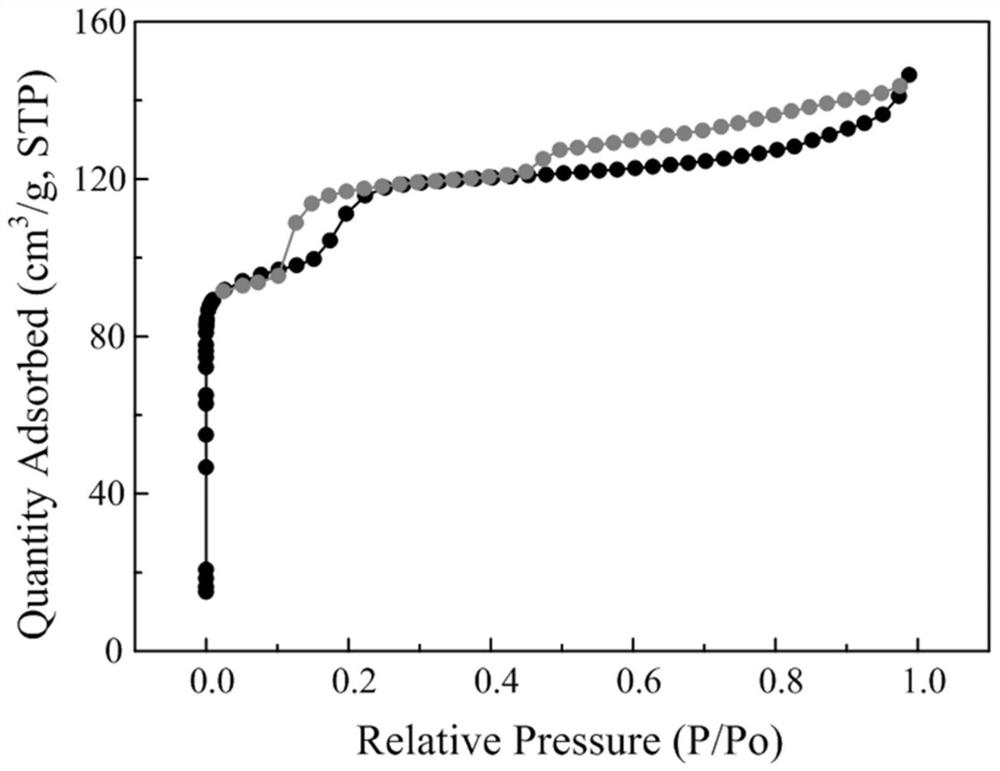

Image

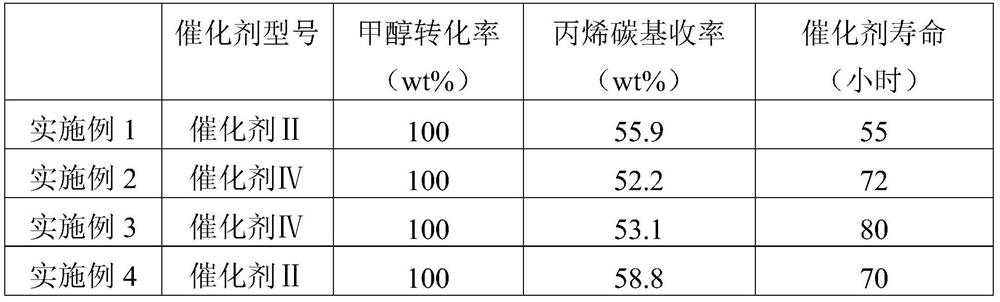

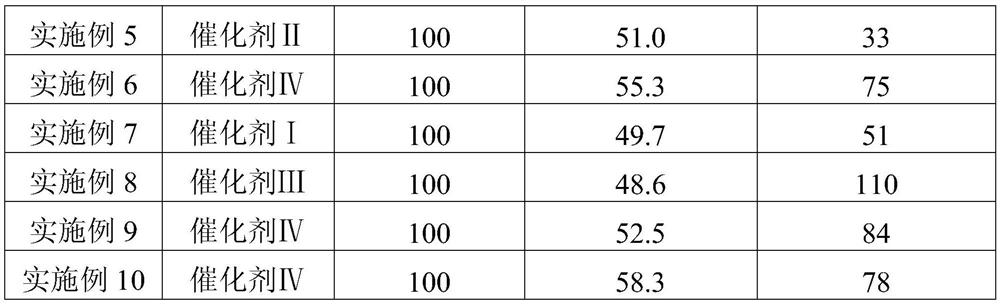

Examples

Embodiment 1

[0050] This embodiment provides a catalyst for the conversion of methanol to propylene and a preparation method thereof, the preparation method comprising the following steps:

[0051] S1, the tetrapropylammonium bromide aqueous solution of 10wt% is added to SiO 2 In the 20wt% water glass aqueous solution, stir at room temperature for 20min; then, under the condition of maintaining stirring, add the sodium metaaluminate aqueous solution with a concentration of 20wt% dropwise, and continue to stir at room temperature for about 3 hours after the dropwise addition, to obtain a mixed liquid, wherein the mass ratio of tetrapropylammonium bromide aqueous solution, water glass aqueous solution and sodium metaaluminate aqueous solution is 1:1:0.2;

[0052] After the stirring is completed, put the mixed solution into a crystallization kettle, and crystallize at 160°C for 36 hours; after the crystallization is completed, the crystallized product is washed, filtered, dried, and roasted i...

Embodiment 2

[0056] This embodiment provides a catalyst for the conversion of methanol to propylene and a preparation method thereof, the preparation method comprising the following steps:

[0057] S1, the tetrapropylammonium bromide aqueous solution of 10wt% is added to SiO 2 20wt% water glass aqueous solution, stirred at room temperature for 20 minutes; then under the condition of maintaining stirring, dropwise added sodium metaaluminate aqueous solution with a concentration of 20wt%, and continued to stir at room temperature for 3 hours after the addition was completed, to obtain a mixed solution , wherein the mass ratio of tetrapropylammonium bromide aqueous solution, water glass aqueous solution and sodium metaaluminate aqueous solution is 1:1:0.2;

[0058] After the stirring is completed, put the mixed solution into a crystallization kettle, and crystallize at 160°C for 36 hours; after the crystallization is completed, the crystallized product is washed, filtered, dried, and calcined...

Embodiment 3

[0065] This embodiment provides a catalyst for the conversion of methanol to propylene and a preparation method thereof, the preparation method comprising the following steps:

[0066] S1, the tetrapropylammonium bromide aqueous solution of 40wt% is added to SiO 2 30wt% water glass aqueous solution, stirred at room temperature for 40min; then under the condition of maintaining stirring, dropwise added a sodium metaaluminate aqueous solution with a concentration of 30wt%, and continued to stir at room temperature for 3 hours after the addition was completed, to obtain a mixed solution , wherein the mass ratio of tetrapropylammonium bromide aqueous solution, water glass aqueous solution and sodium metaaluminate aqueous solution is 2:1:0.1;

[0067] After the stirring is completed, put the mixed solution into a crystallization kettle, and crystallize at 170°C for 24 hours; after the crystallization is completed, the crystallized product is washed, filtered, dried, and calcined in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com