Method for extracting lithium and battery-grade lithium hydroxide monohydrate

A lithium-rich, brine technology, applied in the direction of lithium oxide;/hydroxide, lithium carbonate;/acid carbonate, etc., can solve the problem of low lithium ion yield, lithium hydroxide monohydrate and lithium carbonate Low purity and other problems, to achieve the effect of improving purity, low production cost, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

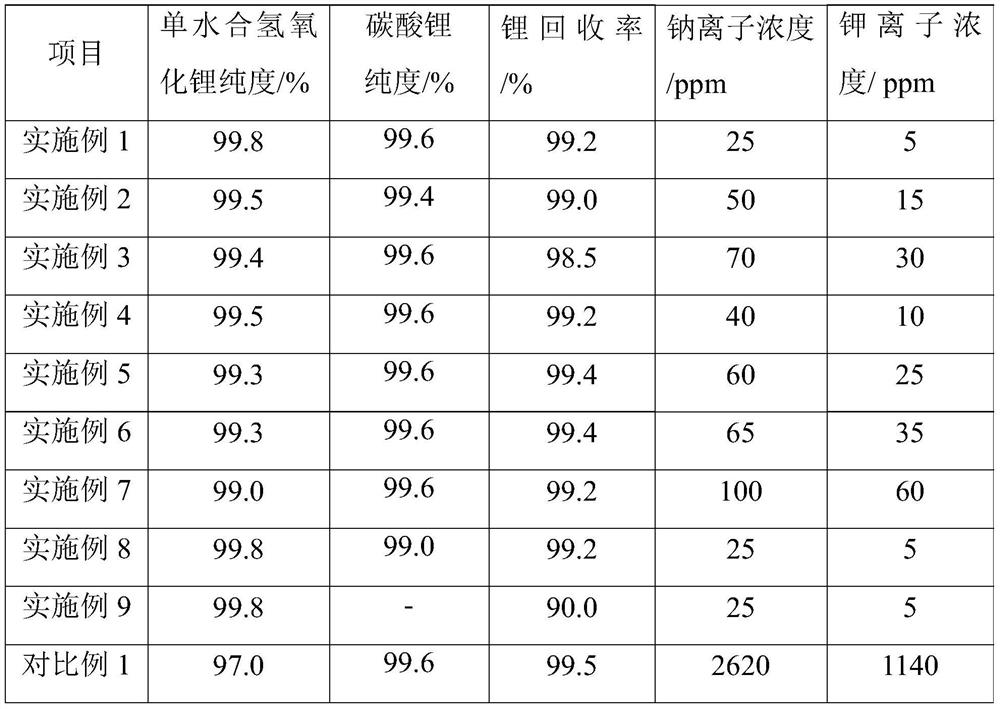

Examples

specific Embodiment approach

[0044] As a specific embodiment, the method may further include: returning the second recrystallization mother liquor to step S4 to mix with the evaporative crystallization precipitate to perform the first dissolution and recrystallization treatment. In another specific embodiment, the method may further include: returning the first recrystallization mother liquor to step S3 to mix with the mixed lye to perform the evaporative crystallization treatment. The recovery rate of comprehensive lithium can be effectively improved by reusing the two times of dissolution and recrystallization mother liquor as the stock solution of the upper stage evaporation crystallization and / or dissolution crystallization.

[0045] According to the present disclosure, the temperature of evaporative crystallization treatment can be 50-100°C, and the crystallization rate is 40-200g / h; preferably, the temperature is 60-85°C, and the crystallization rate is 50-150g / h, so as to further reduce impurities i...

Embodiment 1

[0054] S1. Use the lithium-rich concentrated solution obtained from salt lake brine through aluminum salt lithium adsorbent-nanofiltration-reverse osmosis-nanofiltration-electrodialysis-resin treatment as raw material. The Li ion concentration in the lithium-rich concentrated solution is 7000ppm, and the Na ion concentration is . 4500ppm, K ion concentration is 1685ppm, Ca ion concentration is lower than 1ppm, Mg ion concentration is lower than 1ppm.

[0055] S2. Lithium-rich concentrated solution enters the raw material room in the bipolar membrane system as the original solution. The voltage of a single pair of membranes is 2V, and the membrane current density is 800A / m 2 The bipolar membrane alkali-making treatment is carried out under certain conditions, and the mixed alkali solution of lithium hydroxide, sodium hydroxide and potassium hydroxide with a total alkali molar concentration of 2.1mol / L is obtained, wherein the concentration of lithium hydroxide is 4.06%, and the ...

Embodiment 2

[0061] Prepared by the same method as in Example 1, the only difference is that in step S1, the lithium-rich concentrated solution obtained from salt lake brine through aluminum salt lithium adsorbent-nanofiltration-reverse osmosis-electrodialysis-resin treatment is used as raw material, rich The Ca ion concentration in the lithium concentrated solution is 0.7ppm, the Mg ion concentration is 0.9ppm, the Li ion concentration is 4500ppm, the Na ion concentration is 2890ppm, and the K ion concentration is 1083ppm.

[0062] In step S3, the concentration of Na ions in the mother liquor at the end point of evaporation and crystallization is 8% by weight, and the concentration of K ions is 4.5% by weight.

[0063] In step S4, the concentration of Na ions in the first recrystallization mother liquor is 3.5% by weight, and the concentration of K ions is 2% by weight.

[0064] In step S5, the Na ion concentration in the second recrystallization mother liquor is 0.25% by weight, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com