Synergistic stable compound fertilizer and preparation method thereof

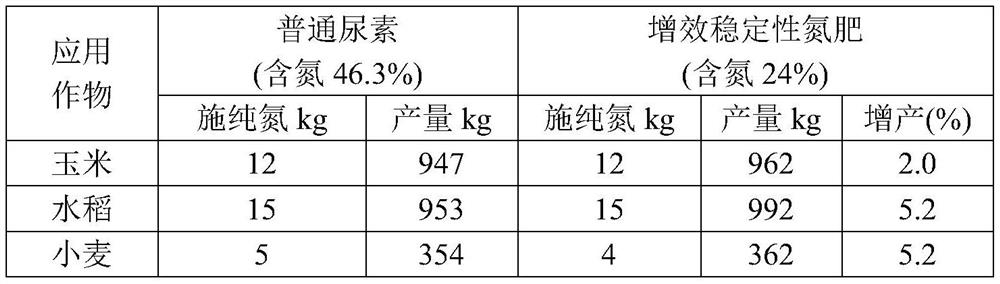

A compound fertilizer and stability technology, applied in urea compound fertilizer, inorganic fertilizer, organic fertilizer and other directions, can solve the problem of low nitrogen utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

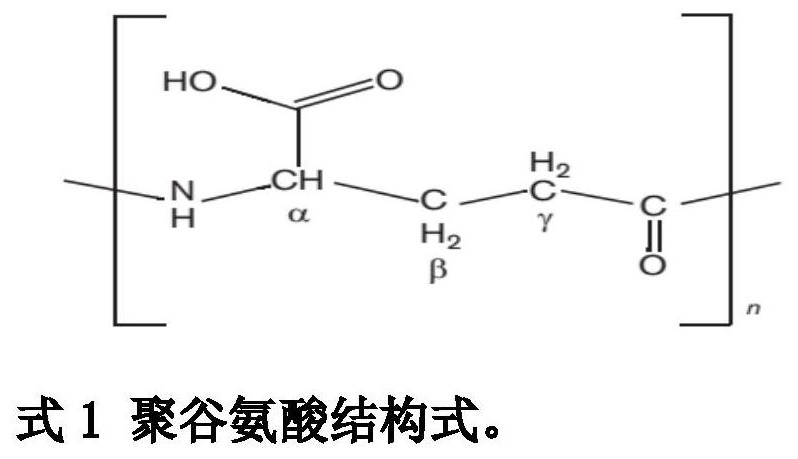

[0026] The ingredients of the synergistic and stable compound fertilizer include urea, superphosphate, potassium sulfate, magnesium, urease inhibitor, and polyglutamic acid.

[0027] Based on 100 parts by weight of urea slurry, add 50 parts of superphosphate, 100 parts of potassium sulfate, 8 parts of magnesium, 5 parts of ammonium thiosulfate, methanol with a volume concentration of 37% that can make ammonium thiosulfate dissolve, and 20 parts Gamma-polyglutamic acid.

[0028] Preparation:

[0029] Based on 100 parts (kg) of urea slurry (molten urea), 5 parts of ammonium thiosulfate are dissolved in 300-500ml (400ml volume concentration here) of 37% methanol (as the carrier of the slow-release agent), fully mixed Dissolve 20 parts of γ-polyglutamic acid in water and mix evenly; superphosphate is pre-dried by the direct heating method of flue gas parallel flow to reduce the moisture content to below 5%, and the inlet temperature of flue gas 400-500°C, and the material outlet...

Embodiment 2

[0031] The ingredients of the synergistic and stable compound fertilizer include urea, triple superphosphate, potassium chloride, sulfur, urease inhibitor, nitrification inhibitor, and γ-polyglutamic acid.

[0032] Based on 100 parts by weight (100 kg) of urea slurry, add 50 parts of superphosphate, 100 parts of potassium chloride, 8 parts of sulfur, 2.5 parts of ammonium thiosulfate, 2.5 parts of 3,4-lutyl Azole phosphate, 300-500 ml (here, 400 ml) of methanol with a volume concentration of 37% capable of dissolving ammonium thiosulfate and 3,4-dimethylpyrazole phosphate, and 20 parts of γ-polyglutamic acid.

[0033] Preparation:

[0034] Based on 100 parts of urea slurry (melted urea), 2.5 parts of ammonium thiosulfate and 2.5 parts of 3,4-dimethylpyrazole phosphate were dissolved in 300-500ml (400ml here) of 37% of the volume concentration Methanol (as the carrier of the sustained release agent), fully mixed; 20 parts of γ-polyglutamic acid was dissolved in water and mixed...

Embodiment 3

[0036] The ingredients of the synergistic and stable compound fertilizer include urea, superphosphate, potassium chloride, nitrification inhibitor, zinc, and γ-polyglutamic acid.

[0037] Based on 100 parts (100 kg) of urea slurry, add 50 parts of superphosphate, 100 parts of potassium chloride, 7 parts of zinc, and 5 parts of 3,4-dimethylpyrazole phosphate to make 3,4 - Dimethylpyrazole phosphate dissolved in 37% by volume methanol, and 20 parts of gamma-polyglutamic acid.

[0038] Preparation:

[0039] Based on 100 parts of urea slurry (molten urea), 5 parts of 3,4-dimethylpyrazole phosphate are dissolved in 300-500ml (400ml here) of 37% methanol (as a slow-release agent) of volume concentration Carrier), fully mixed; dissolve 20 parts of polyglutamic acid in water and mix evenly; calculate the flow rate through the metering pump, add the above two mixed solutions, 7 parts of zinc, 50 parts of superphosphate, and 100 parts of potassium chloride In the urea slurry, use the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com