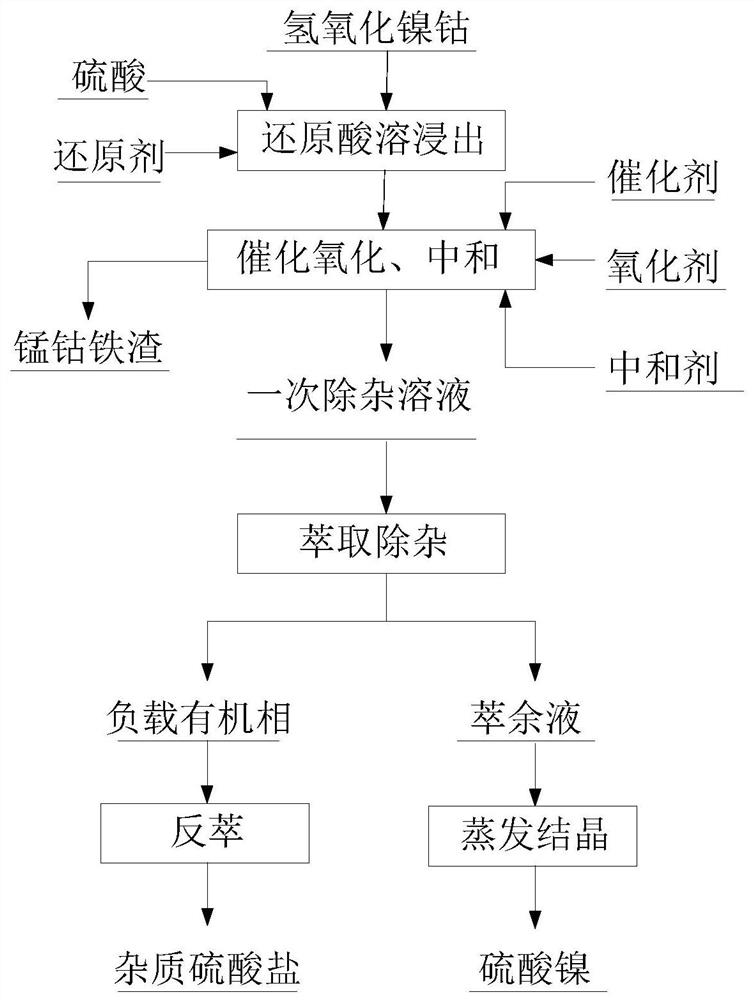

Method for preparing nickel sulfate from cobalt nickel hydroxide

A technology of nickel-cobalt hydroxide and nickel sulfate, applied in the field of hydrometallurgy, can solve the problems of large flow rate of nickel-cobalt separation system, extraction and impurity removal, complicated process flow, etc., so as to reduce equipment investment and occupation, reduce system and simplify preparation. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] MHP nickel-cobalt hydroxide is used as the raw material, its water content is 60%, the dry basis contains 40% nickel, 3.5% cobalt and 6% manganese.

[0043] Atmospheric pressure leaching is adopted, the temperature is 80°C, the leaching time is 2h, the pH is controlled at 2.0, the liquid-solid ratio is 8:1, and the amount of sulfur dioxide introduced is 0.8 times the molar amount of manganese in the system.

[0044] The nickel leaching rate is 99.8%, the cobalt leaching rate is 99.8%, and the manganese leaching rate is 95%.

[0045] Afterwards, pure oxygen is introduced as an oxidant, sodium metabisulfite is added as a catalyst, wherein the catalyst accounts for 5% of the dry weight of the raw material, nickel carbonate is used as a neutralizer, the reaction temperature is 60°C, the leaching time is 10h, the pH is controlled at 4.0, and the liquid-solid ratio is 8: 1.

[0046] The cobalt precipitation rate is 99.9%, and the manganese precipitation rate is 99.5%. The ni...

Embodiment 2

[0050] MHP nickel-cobalt hydroxide is used as the raw material, its water content is 60%, the dry basis contains 40% nickel, 3.5% cobalt and 6% manganese.

[0051] Using 0.4MPa pressure leaching, the temperature is 150°C, the leaching time is 2h, the pH is controlled at 2.0, the liquid-solid ratio is 8:1, and sulfur dioxide is introduced, which is 0.8 times the molar amount of manganese in the system.

[0052] The nickel leaching rate is 99.9%, the cobalt leaching rate is 99.9%, and the manganese leaching rate is 99%.

[0053] Afterwards, pure oxygen is introduced as an oxidant, sodium metabisulfite is added as a catalyst, wherein the catalyst accounts for 5% of the dry weight of the raw material, nickel carbonate is used as a neutralizer, the reaction temperature is 60°C, the leaching time is 10h, the pH is controlled at 4.0, and the liquid-solid ratio is 8: 1.

[0054] The cobalt precipitation rate is 99.9%, and the manganese precipitation rate is 99.5%. The nickel sulfate ...

Embodiment 3

[0058] MHP nickel-cobalt hydroxide is used as the raw material, its water content is 60%, the dry basis contains 40% nickel, 3.5% cobalt and 6% manganese.

[0059] Atmospheric pressure leaching is adopted, the temperature is 80°C, the leaching time is 0.5h, the pH is controlled at 2.0, the liquid-solid ratio is 8:1, and sulfur dioxide is introduced, which is 0.8 times the molar amount of manganese in the system.

[0060] The nickel leaching rate is 99.5%, the cobalt leaching rate is 99.2%, and the manganese leaching rate is 91%.

[0061] Afterwards, pure oxygen is introduced as an oxidant, sodium metabisulfite is added as a catalyst, wherein the catalyst accounts for 5% of the dry weight of the raw material, nickel carbonate is used as a neutralizer, the reaction temperature is 60°C, the leaching time is 10h, the pH is controlled at 4.0, and the liquid-solid ratio is 8: 1.

[0062] The cobalt precipitation rate is 99.9%, and the manganese precipitation rate is 99.5%. The nick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com