Acid-base blended membrane for fuel cell and preparation method thereof

A fuel cell and blend membrane technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as dimensional stability decline, and achieve the effect of reducing swelling rate, high open circuit voltage, and enhancing mechanical stability performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Weigh 20g of norbornene dioic anhydride and 100mL of glacial acetic acid, add them into a 500mL round bottom flask, and stir until completely dissolved under the action of ultrasound. Then 45 g of hexamethylenediamine was added into the round bottom flask, heated to 125° C. in an argon atmosphere, condensed and refluxed for 3 hours, and an orange-yellow transparent solution was prepared.

[0051] The above solution was cooled to room temperature, washed three times with 150mL dichloromethane and 150mL deionized water respectively, neutralized with 1M NaOH solution to pH = 9, then washed three times with 150mL deionized water, anhydrous Na 2 SO 4 Dry, apply to a silica gel chromatography column, and purify with eluent petroleum ether: ethyl acetate = 1: 1 to prepare orange-yellow viscous polymer monomer 3,6-endomethylene-1,2 ,3,6-Tetrahydro-N-(6'-aminohexyl)-cis-phthalimide.

[0052] Weigh 0.3g of the polymer monomer prepared above, dissolve it in 25mL of dry dichlorom...

Embodiment 2

[0056] The basic organic polymer solution was prepared according to the method in Example 1.

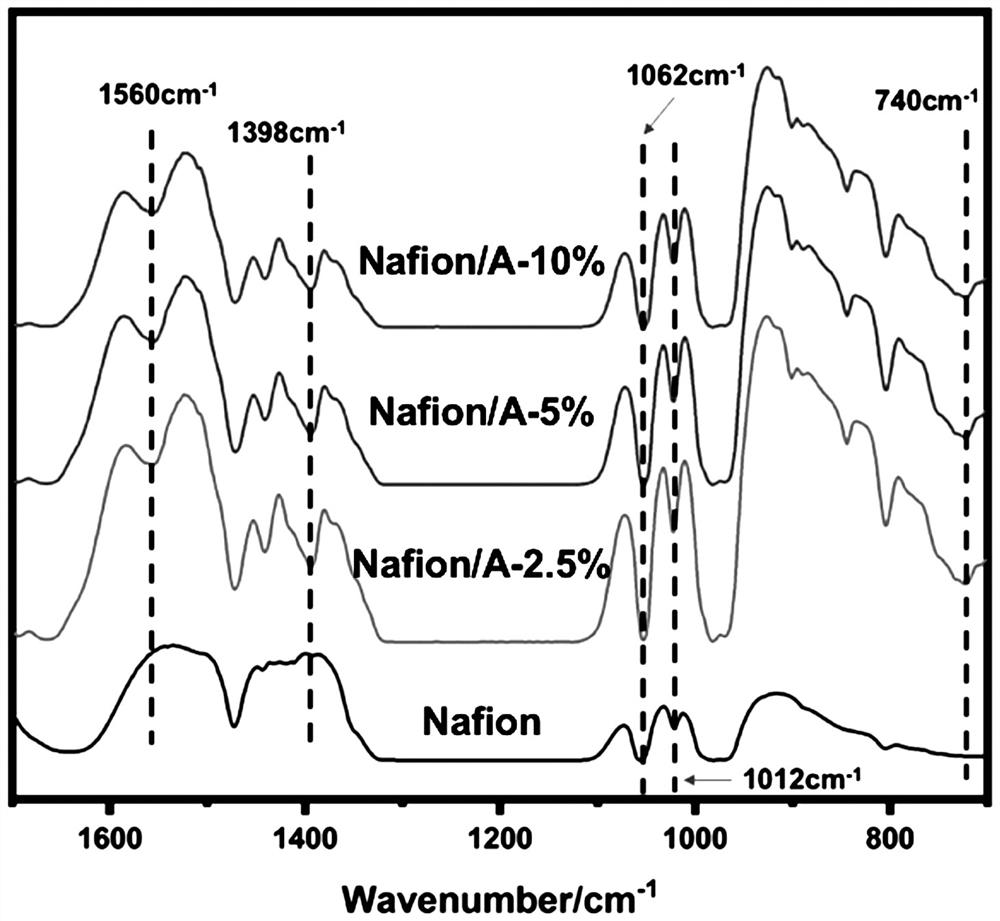

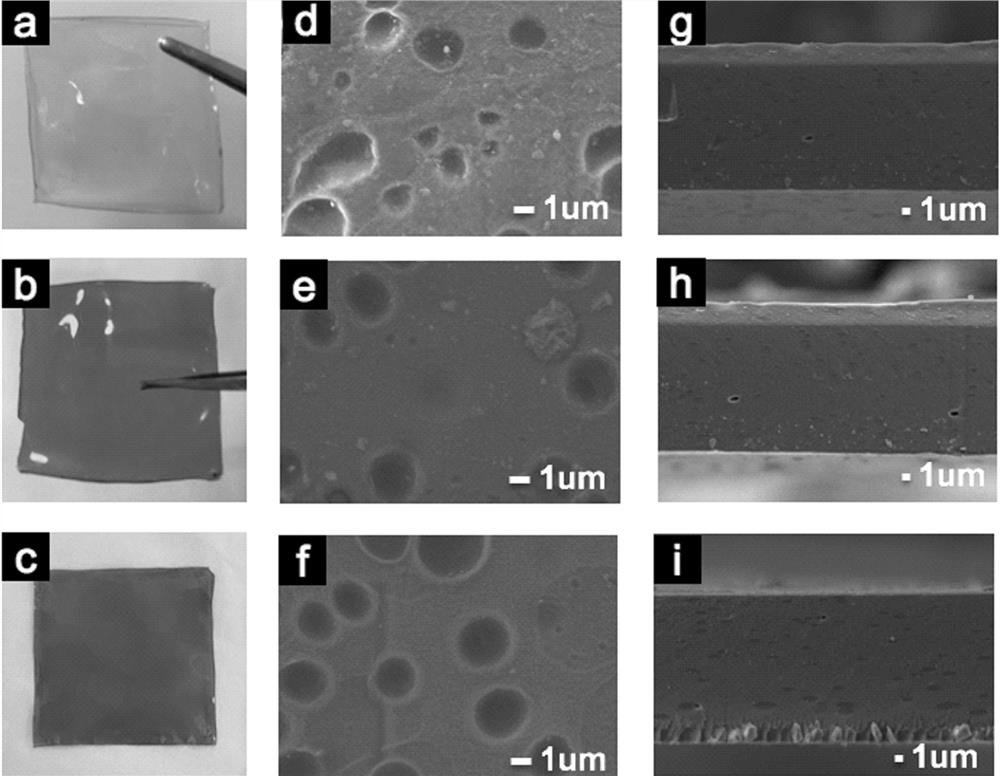

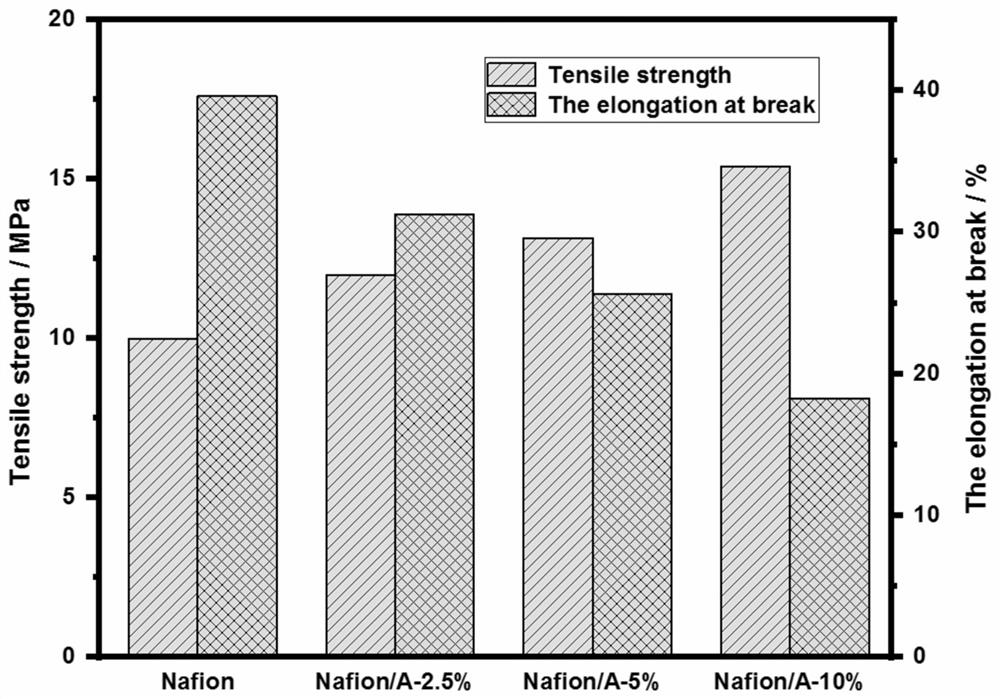

[0057] Weigh 5g of 5% Nafion solution, evaporate the solvent to dryness under vacuum at 60°C, then dissolve it in 15mL of DMF, add 0.877g of the basic organic polymer solution prepared above, and stir and mix for 6h at 60°C under argon atmosphere. Cast the uniformly mixed solution on a 3.5cm×3.5cm glass sheet to form a film, place it in an electric blast drying oven, heat it up to 60°C and dry it for 8 hours, then heat it up to 100°C, and dry it in vacuum for 10 hours to prepare an acid-base blend film .

[0058] The acid-base blend membrane prepared in this example contains 5 wt% of basic organic polymer.

Embodiment 3

[0060] The basic organic polymer was prepared according to the method in Example 1.

[0061] Weigh 5g of 5% Nafion solution, evaporate the solvent to dryness under vacuum at 60°C, then dissolve in 15mL of DMF, add 1.852g of the basic organic polymer solution prepared above, and stir and mix for 6h at 60°C under argon atmosphere. Cast the uniformly mixed solution on 3.5cm×3.5cm tin foil to form a film, place it in an electric blast drying oven, heat it up to 60°C and dry it for 8 hours, then heat it up to 100°C, and dry it in vacuum for 10 hours to prepare an acid-base blend film .

[0062] The acid-base blend membrane prepared in this example contained 10 wt% of a basic organic polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com