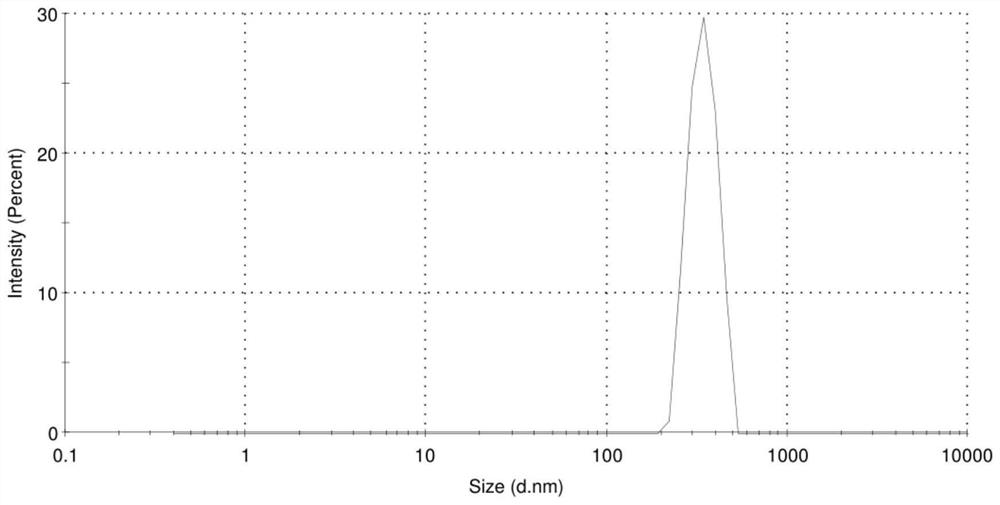

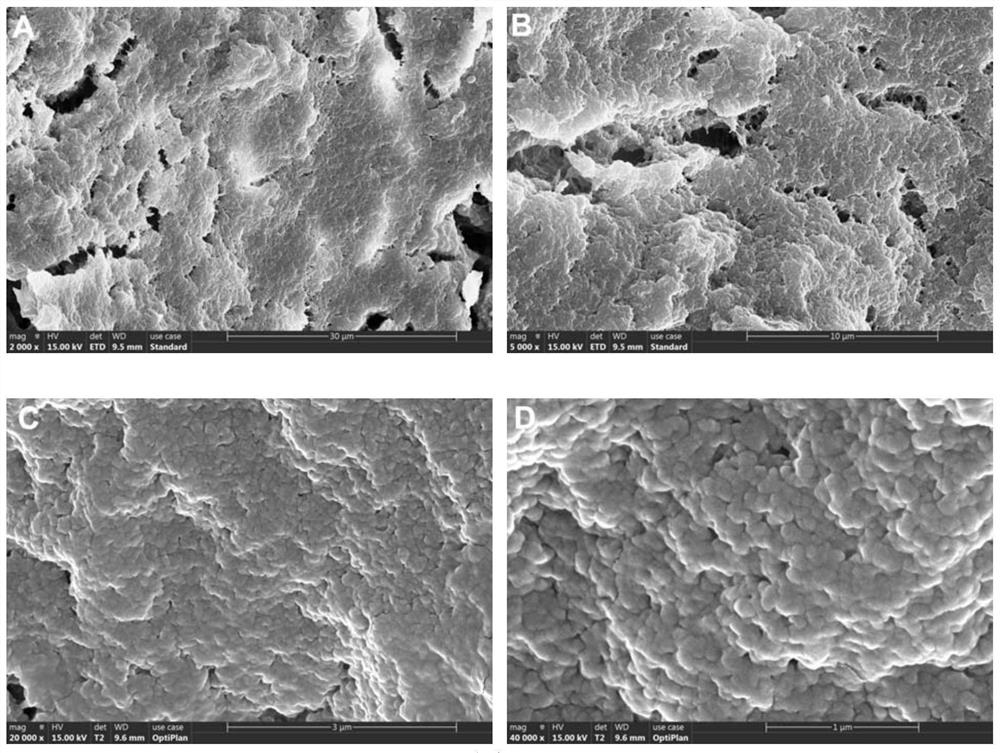

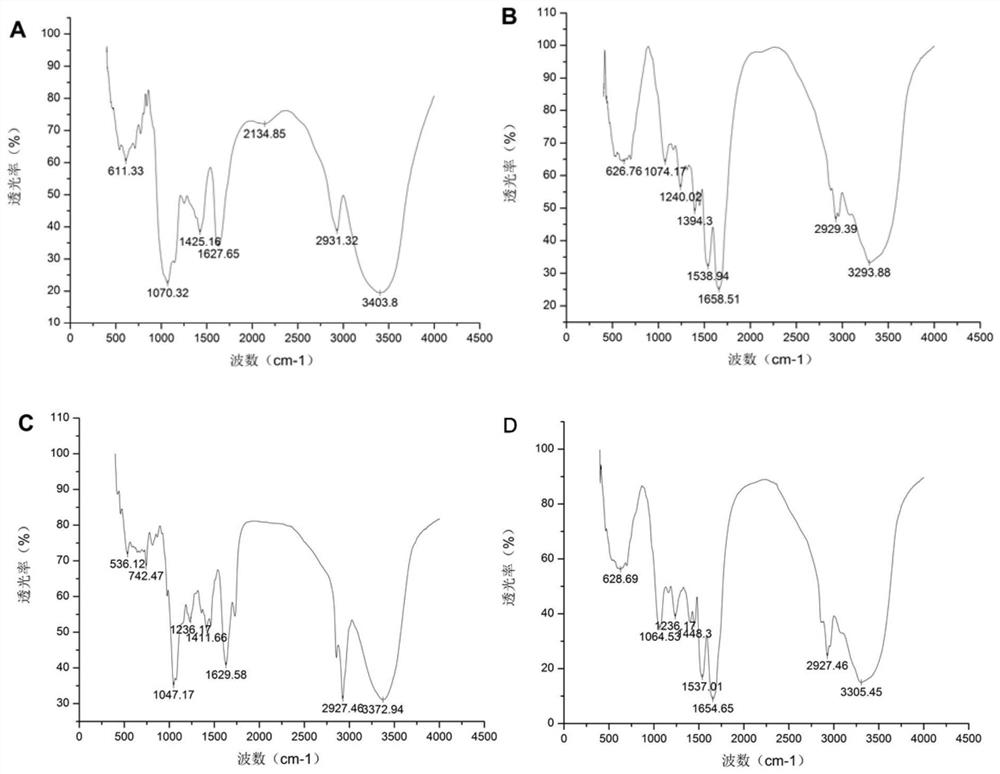

Cicer arietinum saponin microcapsule as well as preparation method and application thereof

A technology of glycoside microcapsules and chickpeas, which is applied in the field of microcapsule preparation, can solve the problems of unseen chickpea protein, poor thermal stability, low entrapment rate and the like, and achieves good sustained release, thermal stability and stability. Good, high encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1, prepare chickpea protein by alkali-dissolving and acid-precipitating method

[0075] Weigh 10g of defatted chickpea flour, add 100mL of distilled water, adjust the pH to 9.0 with 1mol / L NaOH, stir at 500rpm at room temperature for 45min, centrifuge at 4°C and 5000rpm for 20min, collect the supernatant, repeat the above operation, and combine the supernatant solution, use 0.1mol / L HCl to adjust the pH to 4.5, acid precipitation for 1h, centrifuge at 4500g, 4°C for 20min, wash the precipitate with 4°C distilled water, resuspend the precipitate in water, adjust the pH to 7 with 1mol / L NaOH, Freeze-dried to obtain protein powder (chickpea protein).

Embodiment 2

[0076] Embodiment 2, adopt ultrasonic method to modify chickpea protein

[0077] Weigh 1.0 g of the chickpea protein prepared in Example 1, dissolve it in 15 mL of distilled water, stir for 2 min with a high-speed homogenizer at 10,000 rpm, ultrasonicate at room temperature for 30 min at a power of 140 W, and freeze-dry to obtain ultrasonically denatured protein.

Embodiment 3

[0078] Example 3. Preparation of Chickpea Saponin Extract by Ultrasound-Assisted Ethanol Extraction

[0079] Weigh 1.0 g of defatted chickpea flour, add 30 mL of 68% ethanol, and ultrasonicate for 45 min at an ultrasonic temperature of 50 °C and an ultrasonic power of 107 W, filter to obtain the ethanol extract, concentrate the ethanol extract to dryness under reduced pressure, and wash out with 10 mL of distilled water (Dissolve the dry matter after concentration under reduced pressure in distilled water), transfer to a separatory funnel, extract 30 min according to water phase: water saturated n-butanol (volume ratio) = 1:3, 3 times in total, and store in normal The total saponins in the butanol phase were concentrated to dryness under reduced pressure to obtain a crude chickpea saponin extract. The extraction rate of total chickpea saponins is 0.4823%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com