A test method for acid dew point of boiler flue gas based on artificial neural network

An artificial neural network and neural network technology, which is applied in the field of boiler safety and energy saving, can solve the problems of increased cost of test device maintenance and maintenance, complex test process, and many measured parameters, and achieve rich functions, high flexibility, efficiency and accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

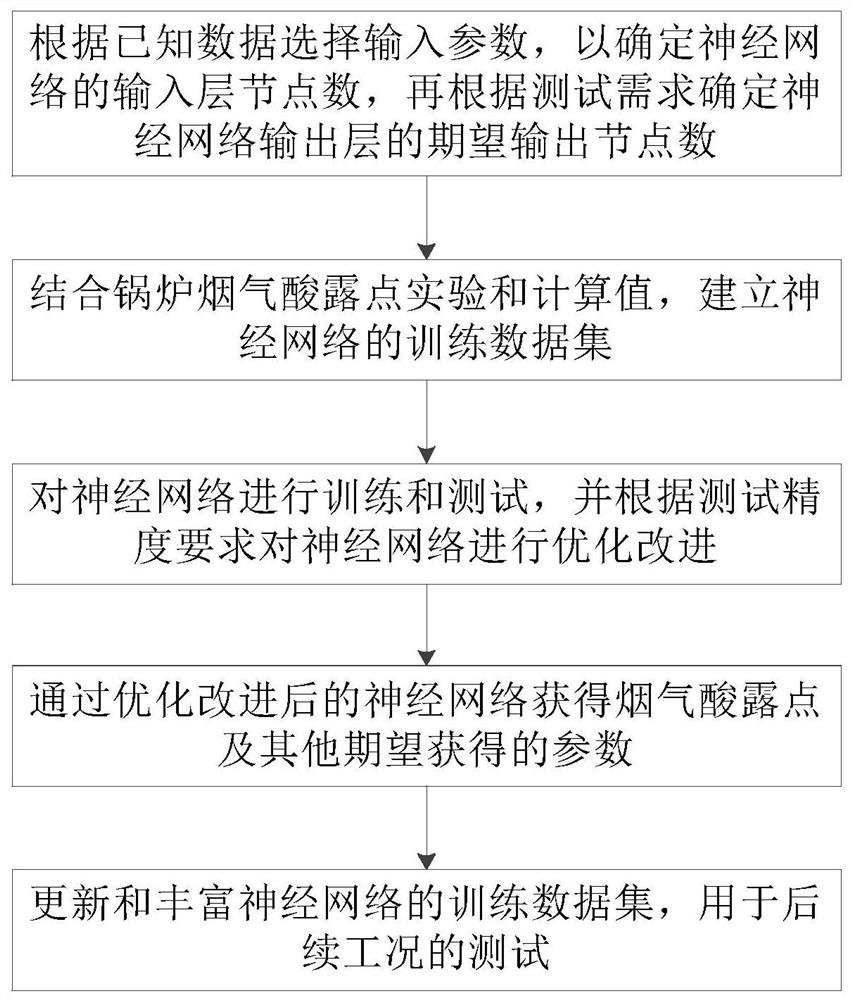

Method used

Image

Examples

Embodiment 1

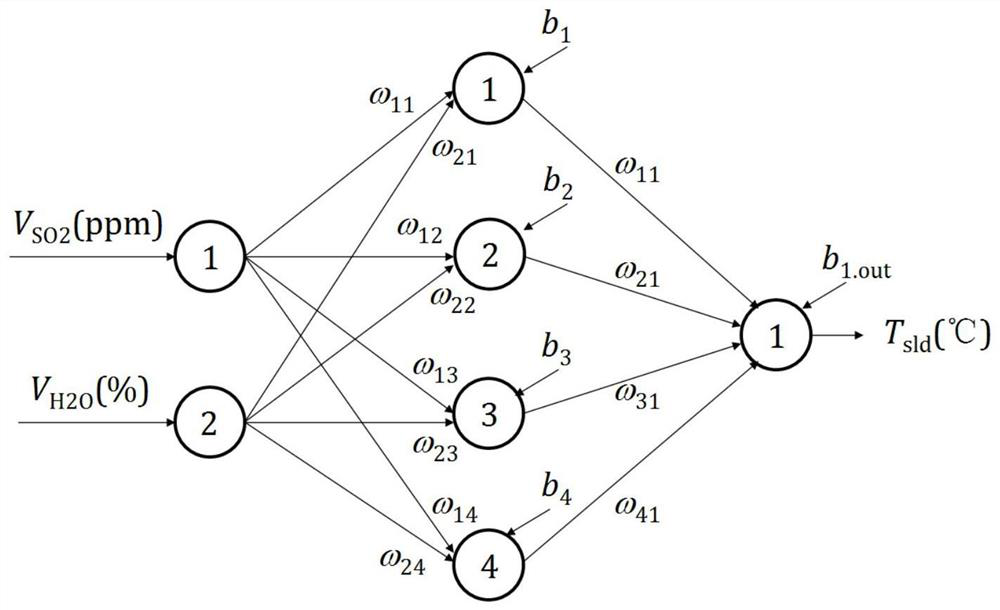

[0045]In this embodiment, the flue gas sulfur dioxide content and the flue gas water vapor content in the boiler flue gas are measured by the flue gas analyzer. This embodiment only tests the acid dew point parameter of the flue gas, regardless of other known data. The neural network The number of nodes in the input layer and output layer are 2 and 1, respectively.

[0046] In this embodiment, the data format of the training data set of the neural network is:

[0047] {input layer: output layer: [T sld ]}

[0048] Before inputting into the neural network, the values of flue gas sulfur dioxide content and flue gas water vapor content are normalized by mean variance, and the value of flue gas acid dew point is normalized by the maximum value.

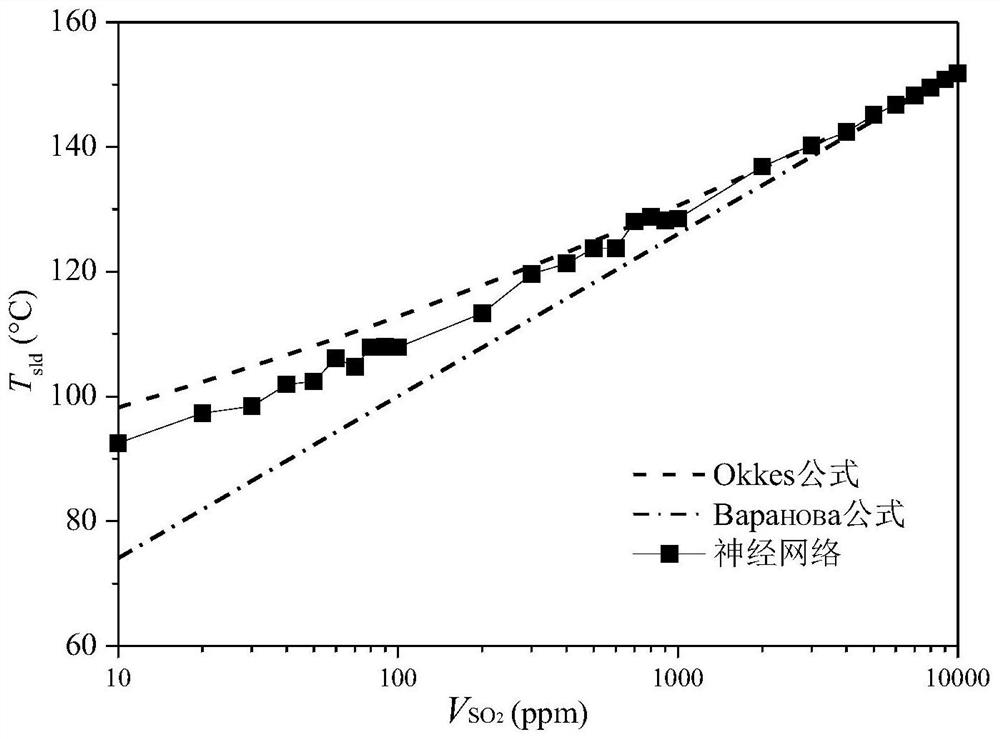

[0049] In this example, 300 sets of data are extracted from the existing flue gas acid dew point experimental data, theoretical / empirical formula calculation data, and literature data, that is, the flue gas acid dew point and the co...

Embodiment 2

[0059] In this example, the power plant boiler with model HG-1100 / 25.4-YM1 is used as the test object. Compared with industrial boilers and heating boilers, the known data of power plant boilers are relatively complete, and the sulfur dioxide content of flue gas at the inlet of the economizer is selected. , flue gas water vapor content, flue gas oxygen content, fuel low calorific value, fuel ash content, and fuel sulfur content are used as input parameters. It is expected to test the flue gas acid dew point, the upper limit of the range of flue gas acid dew point, The lower limit of the acid dew point range and the conversion rate between sulfur dioxide and sulfur trioxide gas in the flue gas, the input layer nodes and output layer nodes of the neural network are determined to be 6 and 4 respectively, and the prototype of the neural network is as follows Figure 4 shown.

[0060] In this embodiment, the data format of the training data set of the neural network is:

[0061] {...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com