Production method of flexible circuit board, produced flexible circuit board and application of flexible circuit board

A technology for flexible circuit boards and preparation steps, applied in the directions of printed circuit manufacturing, printed circuits, printed circuit coatings, etc., can solve problems such as restricting development, and achieve the effects of reducing disconnection, good compactness, and inhibiting electromigration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

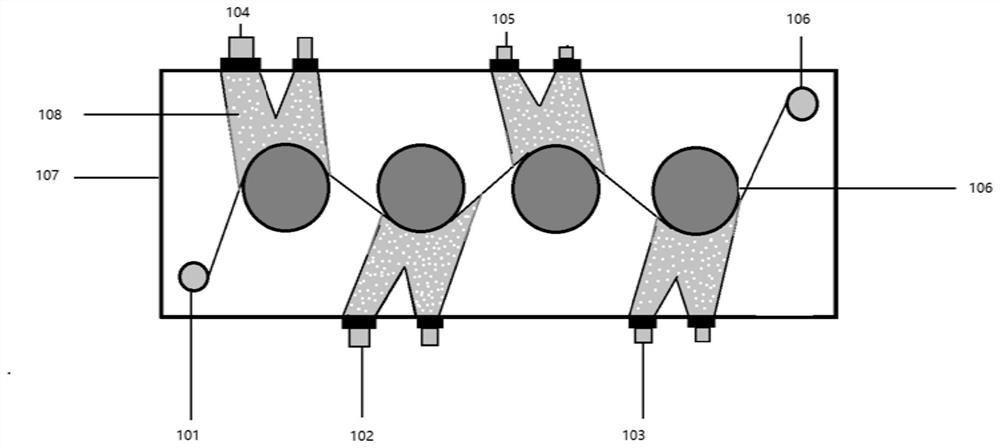

Method used

Image

Examples

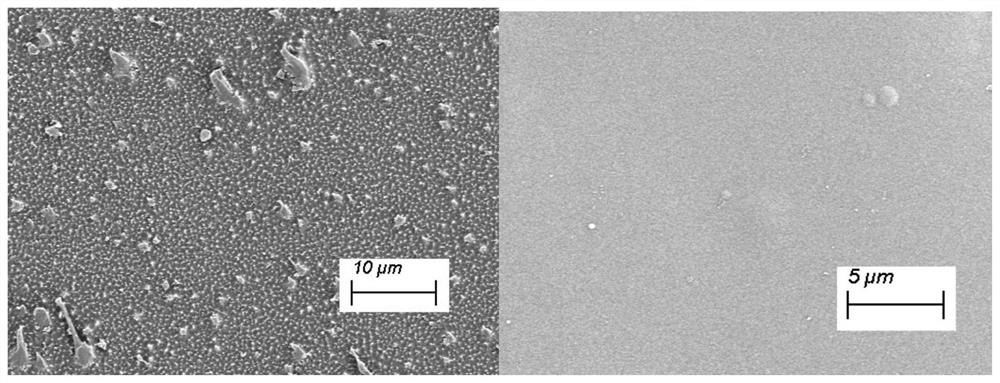

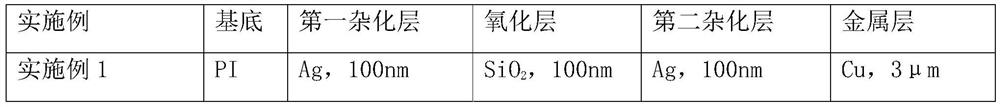

Embodiment 1

[0031] To prepare PI polymer flexible copper clad laminate, follow the steps below:

[0032] (1) Prepare the first hybrid layer, and deposit it on the surface of PI polymer through a high-energy ion beam system to obtain a hybrid layer of polymer and metal ions; the ion beam energy is 12keV, and the treatment dose is 1*10 18 ions / cm 2 , vacuum degree 5*10 -3 Pa, the target is Ag target, the thickness is 100nm;

[0033] (2) Prepare an oxide layer, prepare an insulating oxide by vapor deposition in the first hybrid layer, SiO2 as an evaporation source, and the working pressure of the vacuum chamber is 5.0×10 -3 Pa, the substrate temperature is 150°C, the power is 20kW, and the oxide thickness is 100nm;

[0034] (3) Prepare the second hybrid layer, deposit a high-energy ion beam on the surface of the first oxide layer to obtain a hybrid layer of polymer and metal ions, the ion beam energy is 12keV, and the treatment dose is 1*10 18 ions / cm 2 , vacuum degree 5*10 -3 Pa, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com