Pulse electric field treatment preparation method of gingerol with high content of 6-shogaol

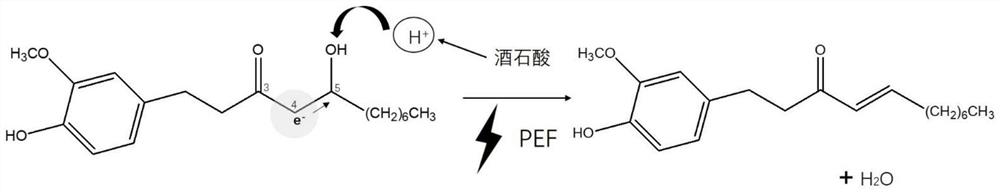

A pulsed electric field and shogaol technology, which is applied in the field of extraction and preparation of biologically active components, can solve the problems of complex gingerol purification technology, high production cost, unsuitability for industrial production, etc., so as to meet the requirements of high-efficiency and safe industrial production and inhibit high-temperature oxidation. effect, to achieve the effect of low temperature and high efficiency extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

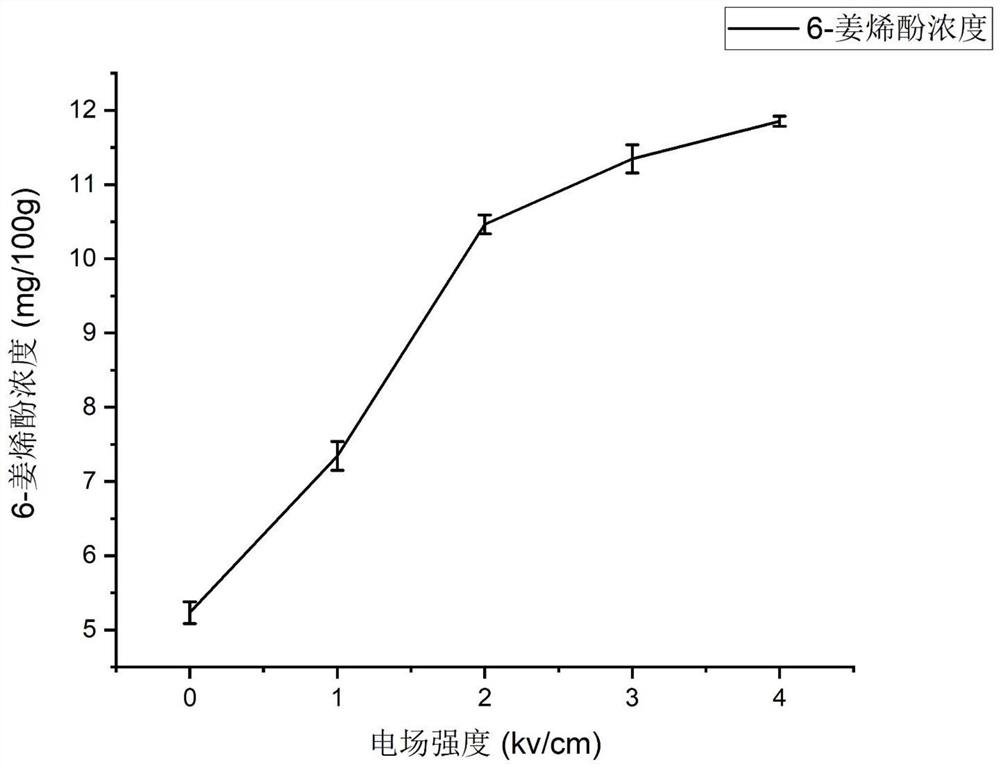

Examples

Embodiment 1

[0052] Select intact and undamaged turmeric, clean it, and slice it with a slicer. The thickness of the ginger slices is 2-3 mm. Dry the ginger slices. The water content of the dried ginger slices is about 7%. Grind them with a grinder and pass through a 40-mesh sieve. dried ginger powder;

[0053] Take 5g of prepared freeze-dried ginger powder and add 80% ethanol solution, the ratio of solid to liquid (g / ml) is 1:20, stir and mix evenly, add 0.1M tartaric acid solution dropwise, adjust the pH to 4.0, and make acidic ginger powder dispersion;

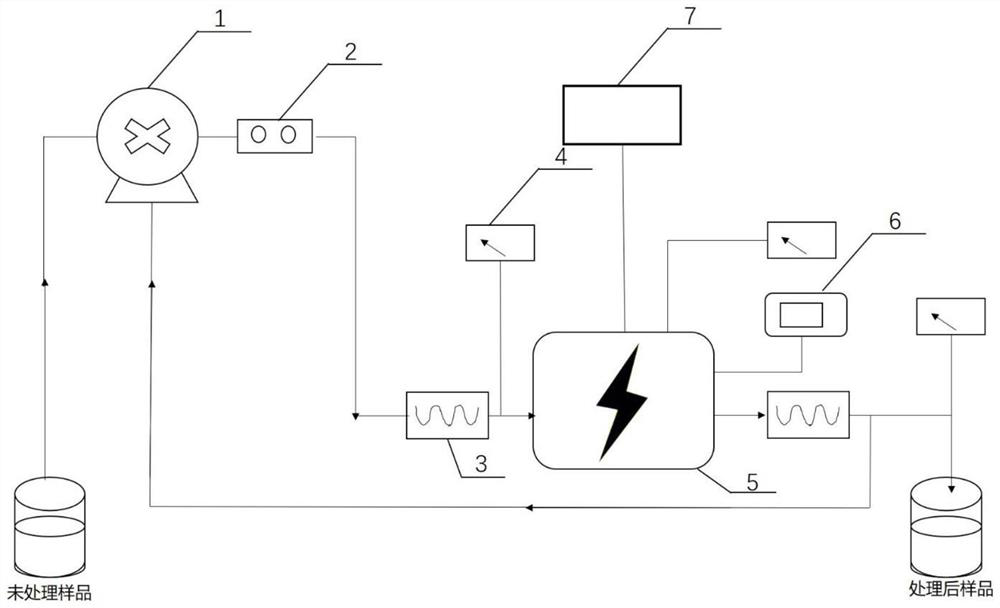

[0054] Put the acidic ginger powder dispersion into figure 2 The pulsed electric field treatment system shown in the figure is sequentially transported to the high-voltage pulsed electric field treatment chamber 5 through the pump 1 and the circulating condensing device 3 for pulsed electric field treatment. The flow rate of the acidic ginger powder dispersion is adjusted to 1.0t / h by the flowmeter 2, and the treatment temperature is...

Embodiment 2

[0058] Select intact and undamaged turmeric, clean it, and slice it with a slicer. The thickness of the ginger slices is 2-3mm. Dry the ginger slices. The water content of the dried ginger slices is about 8%. Grind them through a grinder and pass through 50 meshes Sieve to get dried ginger powder; get 5g of prepared freeze-dried ginger powder and add 70% ethanol solution, the ratio of solid to liquid (g / ml) is 1:15, stir and mix evenly, add dropwise 0.2M tartaric acid solution, adjust the pH to 5. Prepare acidic ginger powder dispersion;

[0059] Put the obtained acidic ginger powder dispersion into figure 2 The pulsed electric field treatment system is shown for treatment. It is sent to the high-voltage pulse electric field treatment chamber 5 through the pump 1 and the circulating condensing device 3 to receive the pulse electric field treatment. The flow rate of the acidic ginger powder dispersion is adjusted to 0.9t / h by the flowmeter 2, and the treatment temperature is...

Embodiment 3

[0061] Select intact and undamaged turmeric, clean it, slice it with a slicer, the thickness of the ginger slice is 2-3mm, dry the ginger slice, the moisture content of the dried ginger slice is about 9%, grind it through a grinder, and pass through a 50-mesh sieve , to get dried ginger powder; get 5g of prepared freeze-dried ginger powder and add 60% ethanol solution, the ratio of solid to liquid (g / ml) is 1:10, stir and mix evenly, add dropwise 0.3M tartaric acid solution, adjust pH to 3 , making acidic ginger powder dispersion;

[0062] Put the obtained acidic ginger powder dispersion into figure 2 The pulsed electric field treatment system is shown for treatment. It is sent to the high-voltage pulse electric field treatment chamber 5 through the pump 1 and the circulating condensing device 3 to receive the pulse electric field treatment. The flow rate of the acidic ginger powder dispersion is adjusted to 0.5t / h by the flow meter 2, and the treatment temperature is adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com