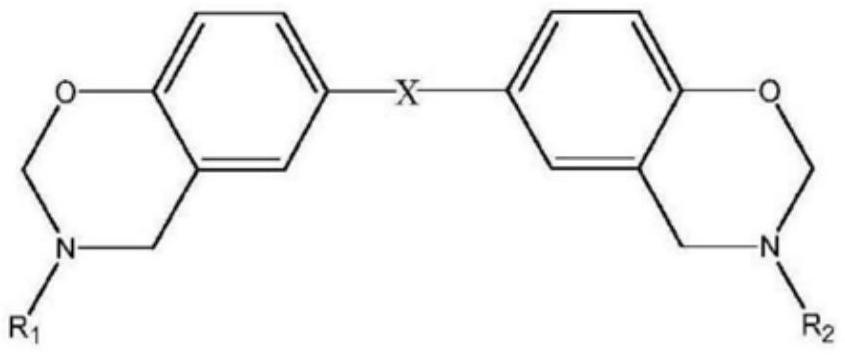

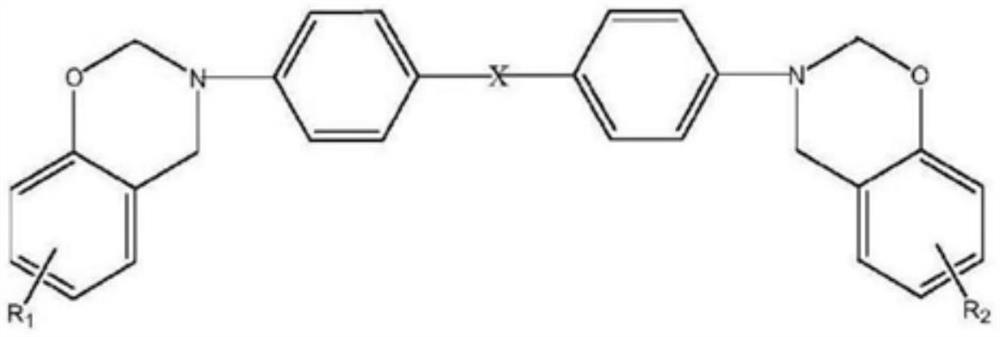

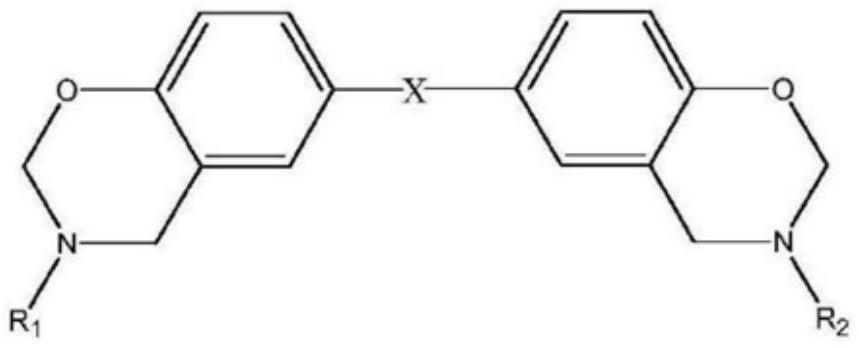

Benzoxazine-containing curable resin composition and preparation method thereof

A benzoxazine and curing resin technology, applied in the field of composite materials, can solve the problems of low crosslinking density, high brittleness of the cured product, and high curing temperature, and achieve the effects of high toughness mechanical properties, excellent mechanical properties, and lowering curing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dissolve 50 parts of dihydric phenol type benzoxazine resin Ba-BOZ, 40 parts of bisphenol A type epoxy resin E51, and 10 parts of amino-terminated nitrile rubber (ATBN) in acetone, and prepare a concentration of 50% Solution, after the solution is stirred evenly, use T700 carbon fiber unidirectional fabric to prepare prepreg, and test the volatile content and resin content of the prepared prepreg. The volatile content of the prepreg is 1.5%, and the resin content is 35.2%.

[0033] Carbon fiber reinforced benzoxazine resin-based composite laminates were prepared by autoclave molding process, cured at 160°C for 10 hours, and then cooled to room temperature. The prepared composites were cut into standard samples according to regulations, and tested in the universal material test The compressive strength and interlaminar shear strength of the composite materials were tested on the machine, and the performance data are shown in Table 1.

Embodiment 2

[0035] Dissolve 50 parts of dihydric phenol type benzoxazine resin Ba-BOZ, 10 parts of bisphenol A type epoxy resin E51, and 40 parts of amino-terminated nitrile rubber (ATBN) in acetone to prepare a concentration of 50%. Solution, after the solution is stirred evenly, use T700 carbon fiber unidirectional fabric to prepare prepreg, and test the volatile content and resin content of the prepared prepreg. The volatile content of the prepreg is 1.4%, and the resin content is 34.8%.

[0036] Carbon fiber reinforced benzoxazine resin-based composite laminates were prepared by autoclave molding process, cured at 160°C for 10 hours, and then cooled to room temperature. The prepared composites were cut into standard samples according to regulations, and tested in the universal material test The compressive strength and interlaminar shear strength of the composite materials were tested on the machine, and the performance data are shown in Table 1.

Embodiment 3

[0038] Dissolve 50 parts of dihydric phenol type benzoxazine resin Ba-BOZ, 20 parts of bisphenol A type epoxy resin E51, 20 parts of carboxyl-terminated nitrile rubber (CTBN) and 10 parts of flame retardant in acetone to prepare A solution with a concentration of 50%. After the solution is stirred evenly, a prepreg is prepared using a T700 grade carbon fiber unidirectional fabric. The volatile matter and resin content of the prepared prepreg are tested. The volatile matter of the prepreg is 1.5%, and the resin content is 35.1%.

[0039] Carbon fiber reinforced benzoxazine resin-based composite laminates were prepared by autoclave molding process, cured at 160°C for 10 hours, and then cooled to room temperature. The prepared composites were cut into standard samples according to regulations, and tested in the universal material test The compressive strength and interlaminar shear strength of the composite materials were tested on the machine, and the performance data are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com